For electronic devices, efficient battery management is essential if you want to maintain the optimal performance of your equipment. Battery boards are such an important component for power distribution, protection, and control for a wide range of applications. Let’s learn what a battery board is, learn about the three types of battery boards, as well as find out how they work, their applications, and other things about battery boards.

Definition of Battery Board

A battery board is a specialized circuit board designed to manage and regulate the power supply from batteries. Its primary function is to seamlessly integrate batteries into electronic devices, ensuring efficient power delivery, protection against voltage fluctuations, and intelligent monitoring of battery health. Battery boards are available in various types to cater to different battery chemistries and configurations.

Essential Components of Battery Protection Board

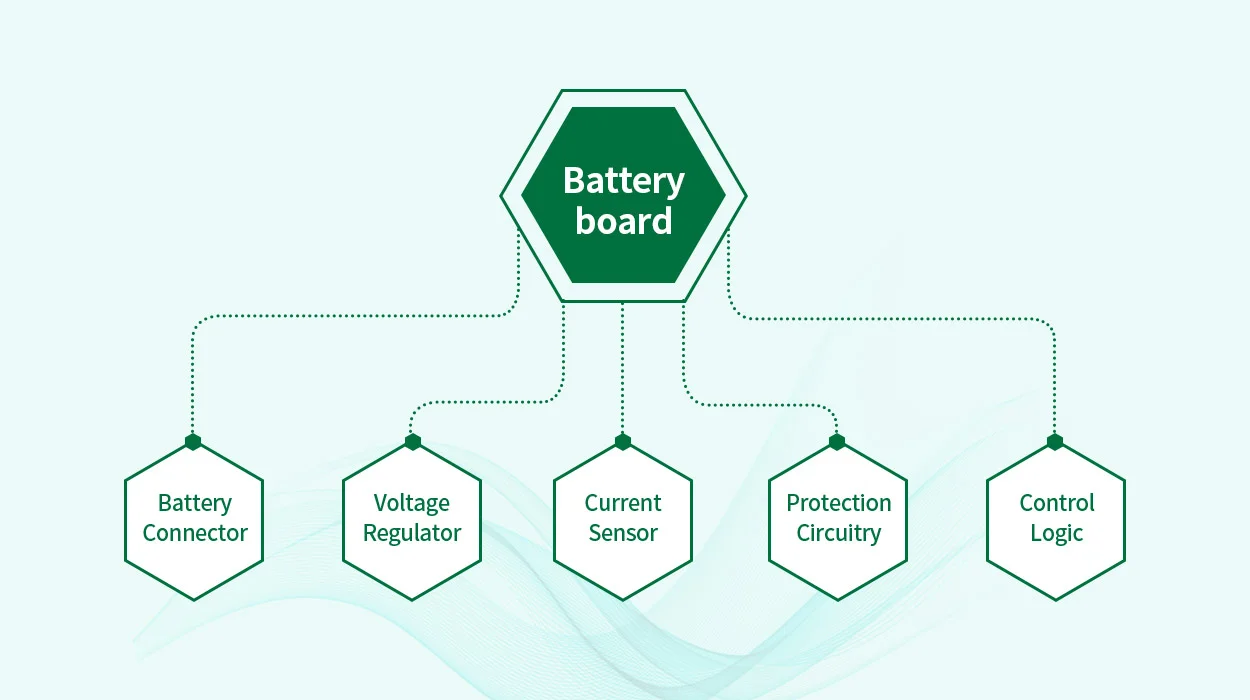

Battery board consists of several essential components that work together to manage the power supply. These components include:

Battery Connector: This physical interface connects the battery cells to the board, allowing power transfer and communication.

Voltage Regulator: The voltage regulator controls the output voltage to match the requirements of the electronic device, ensuring a stable and regulated power supply.

Current Sensor: The current sensor measures the flow of current in and out of the battery, enabling accurate monitoring and protection against overload or short circuits.

Protection Circuitry: The protection circuitry safeguards the battery and the connected device by preventing overcharging, over-discharging, and excessive current flow. It enhances safety and extends battery life.

Control Logic: The control logic provides intelligent management of the battery system. It incorporates features such as charging control, state-of-charge estimation, and communication interfaces.

3 Types of Battery Boards

Lithium-ion (Li-ion) Battery Boards: The lithium battery BMS board is designed specifically for Li-ion batteries, which are widely used in various portable electronic devices such as smartphones, laptops, and electric vehicles. They provide accurate voltage control and advanced safety measures, including safeguards against overcharging, over-discharging, and short-circuit incidents.

Lithium-polymer (LiPo) Battery Boards: LiPo battery boards are tailored for lithium-polymer batteries, which are similar to Li-ion batteries but utilize a different electrolyte composition. They are known for their higher energy density and flexibility in shape and size, making them suitable for applications where space and weight are critical, such as drones, wearables, and remote control vehicles.

Nickel-Cadmium (NiCd) Battery Boards: NiCd battery boards are designed for nickel-cadmium batteries, which were widely used in the past but have become less common due to environmental concerns. NiCd batteries have a high discharge rate and good performance in extreme temperatures, making them suitable for certain applications like emergency lighting, power tools, and medical devices.

What Battery Board Brings?

Battery boards play a vital role in powering electronic devices efficiently and reliably. Here are some key reasons highlighting their importance:

Power Regulation: Battery boards ensure the optimal delivery of power, matching the voltage requirements of the connected electronic device. This regulation prevents damage caused by overvoltage or undervoltage, enhancing the longevity of the device.

Protection and Safety: The protection circuitry in battery boards prevents hazards such as overcharging, over-discharging, and short circuits. These characteristics help reduce hazards, safeguard the integrity of the battery cells, and guarantee the secure functioning of the device.

Battery Monitoring: Battery boards facilitate the live tracking of battery key parameters such as voltage, current, and temperature. This monitoring allows users to estimate the state of charge accurately and make informed decisions about battery usage and replacement.

Enhanced Efficiency: By optimizing power delivery and minimizing energy losses, battery boards contribute to overall system efficiency. They help maximize the utilization of battery capacity, extending the runtime of devices and reducing the frequency of recharging or battery replacement.

Reliable Performance: Battery boards play a vital role in guaranteeing a steady and reliable power source, thereby minimizing the chances of unforeseen shutdowns or operational glitches. This level of dependability holds immense significance in critical scenarios where uninterrupted power is indispensable, including medical devices and industrial equipment.

Intelligent Battery Management: With built-in control logic, battery boards offer advanced features like charging control, state-of-charge estimation, and communication interfaces. These capabilities enable intelligent battery management, allowing users to monitor battery health, optimize charging cycles, and integrate the battery system with the broader device ecosystem.

Where do Battery Boards Apply?

Battery boards find applications in a wide range of industries and devices. Here are some notable applications:

Consumer Electronics: Battery boards power smartphones, tablets, laptops, wearable devices, and portable audio/video equipment, providing efficient and reliable power management.

Medical Devices: Battery boards play a vital role in medical devices like patient monitoring systems, infusion pumps, and portable medical equipment, guaranteeing continuous and secure functionality.

Electric Vehicles: Battery boards play a vital role in managing the power supply, charging, and overall performance of electric vehicle battery systems, enabling efficient and reliable transportation.

Renewable Energy Systems: Battery boards are utilized in solar energy storage systems, enabling efficient energy capture, storage, and distribution for off-grid or backup power applications.

Industrial Equipment: Battery boards are essential for powering industrial equipment such as robotics, unmanned aerial vehicles (UAVs), and remote monitoring systems, ensuring reliable and uninterrupted operation in challenging environments.

IoT Devices: Battery boards enable efficient power management in Internet of Things (IoT) devices, allowing for wireless communication, remote monitoring, and extended battery life.

Design Considerations for Battery Boards

When designing or selecting a battery protection circuit board, there are several important factors to consider:

Battery Chemistry and Configuration: Ensure that the battery board is compatible with the specific battery chemistry (e.g., Li-ion, LiPo, NiCd) and configuration (e.g., series, parallel) you intend to use. Different battery chemistries have distinct voltage and current characteristics, requiring appropriate voltage regulation and protection mechanisms.

Power Requirements: Take into account the power needs of the electronic device or system that the battery board will supply. This includes the required voltage level, current capacity, and any additional power features such as fast charging or power delivery.

Safety and Protection: Look for battery boards with robust protection circuitry to safeguard the battery and connected devices against overcharging, over-discharging, and excessive current flow. Advanced features like temperature monitoring and fault detection can enhance safety and prevent potential hazards.

Form Factor and Integration: Consider the physical dimensions and form factor of the battery board to ensure compatibility with the intended application. Some boards may be designed for specific device types or form factors, while others offer flexibility for integration into various systems.

Efficiency and Power Conversion: Evaluate the efficiency of the voltage regulator and power conversion circuitry on the battery board. Higher efficiency translates to better power utilization and longer battery life.

Industry Trends and Innovations of Battery Board

The battery sector is in a constant state of evolution, propelled by technological progress and evolving market requirements. Some notable trends and innovations include:

Increased Energy Density: Battery boards are being developed to accommodate high-energy-density battery chemistries, enabling longer device runtimes and enhanced portability.

Fast Charging Technologies: Innovations in charging circuitry and protocols are improving the charging speed and efficiency of battery systems, reducing downtime, and enhancing user convenience.

Safety Enhancements: Battery boards are incorporating advanced safety features such as thermal runaway prevention, smart cell balancing, and comprehensive protection mechanisms to ensure safe operation in diverse applications.

Environmental Sustainability: The industry is focusing on developing eco-friendly battery solutions, including recyclable materials, sustainable manufacturing processes, and improved energy efficiency.

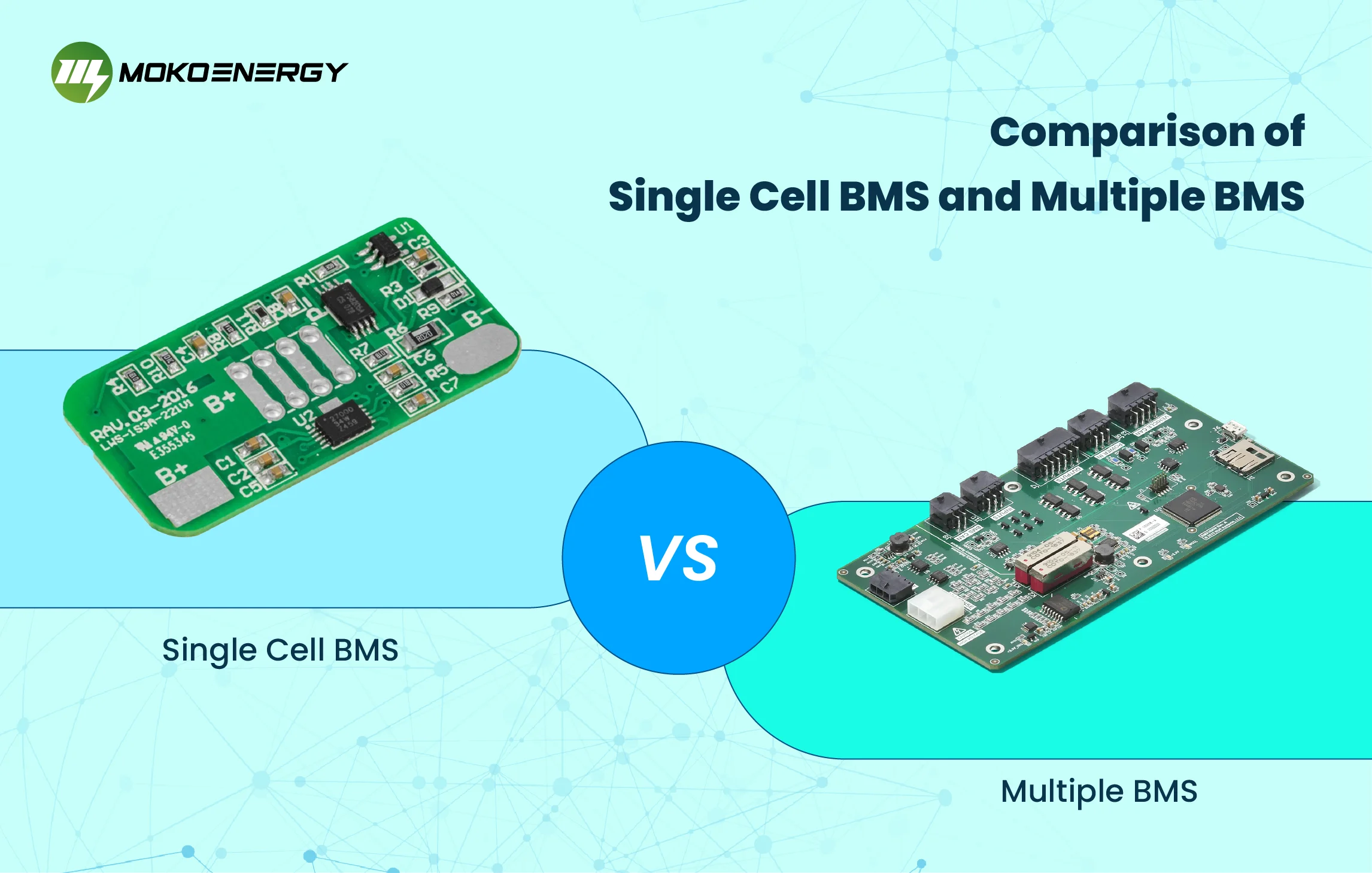

Battery Boards vs. BMS

It’s important to differentiate between battery boards and battery management systems. While battery boards focus on power distribution, protection, and control within a device or system, a BMS is a more comprehensive solution that oversees the entire battery pack. A BMS typically consists of multiple battery charger boards connected to monitor and manage individual battery cells or modules in a larger lithium battery pack. BMS functionality may include cell balancing, state-of-charge estimation, thermal management, and advanced monitoring and diagnostic capabilities.

How to Choose Between Battery Boards and BMS

When deciding between a battery board and a BMS, consider the following factors:

Battery System Complexity: Assess the complexity of your battery system. If it involves multiple cells or requires advanced monitoring and balancing functionalities, a BMS may be more suitable.

Application Requirements: Evaluate the power demands, form factor constraints, and communication needs of your application. Battery boards are ideal for simpler applications, while BMS offers more comprehensive features for advanced systems.

Safety Considerations: A BMS with advanced protection features and precise monitoring capabilities should be considered if safety is a top priority, particularly in critical applications.

Lithium Battery BMS Price: Battery Boards are generally more cost-effective compared to BMS, as they offer basic battery management functionality without additional advanced features. BMS solutions, with their comprehensive features and versatility, tend to be more expensive.

Where to Buy Battery Board?

All electronic components related to intelligent BMS battery management can be purchased from MOKOEnergy, including battery protection boards. Battery protection boards, also known as Battery Protection Circuit Modules (PCM), are the core components of a battery management system used to monitor and protect batteries from faults such as overcharging, over-discharging, and short circuits. MOKOEnergy’s battery board service is highly acclaimed by businesses and individuals. Let’s take a look at their advantages

Highlights of MOKOEnergy’s Battery Boards

- Adhesive Technology: MOKOEnergy’s protection board adopts adhesive technology, which provides better heat dissipation in the field of low-speed power BMS. The adhesive used is a type of injection thermal glue, ensuring that electronic components are securely fixed on the PCB board. Additionally, the adhesive material has excellent thermal conductivity.

- Compatibility with Various Battery Chemistries: MOKOEnergy’s battery board is designed to support different battery chemistries, including lithium-ion batteries, polymer battery protection board lithium, and lead-acid batteries, offering versatility and flexibility for various applications.

- Advanced Protection Features: The battery board incorporates comprehensive protection mechanisms such as overcharge protection, over-discharge protection, and short-circuit protection to ensure the safety and lifespan of the battery system.

- Quality Assurance: Our production processes and quality management system adhere to international standards and have obtained certifications such as ISO9001:2015, ISO13485, ROHS, UL, CE, FCC, and UL, guaranteeing product quality and stability.

- Flexibility and Scalability: With flexibility and scalability, MOKOEnergy can adjust and expand its solutions according to specific customer requirements, ensuring maximum satisfaction and meeting customer demands to the fullest extent.

Conclusion

Battery boards are vital in efficient power management, offering power distribution, protection, and control for various applications. Understanding their pin configuration, design considerations, and the differences between battery boards and BMS aids in selecting the appropriate solution for your needs. When searching for reliable battery board manufacturers, MOKOEnergy stands as a trusted option, providing high-quality battery boards, customization capabilities, and expertise in battery system integration. If you need any assistance, feel free to contact us anytime!

CONTINUE READING ABOUT THE BATTERY BOARD