Contract BMS OEM&ODM Service

Maximise Safety, Performance, and Longevity

for your lithium battery with

MOKOEnergy BMS & PCM

Types of BMS Battery Protection Board on Different Market

MOKOEnergy designs, produces, assembles, and tests BMS Battery Management Systems to ensure safety and reliability.

3S 12V Lithium BMS Battery Protection Board for Electric Drill

3S 12V Lithium Battery BMS PCB Board for Electric Screwdriver

4S 16V BMS Lithium Battery Protection Board for Electric Vehicles Garden Tools

12.8V LifePO4 BMS for Solar Generator

21V Lithium Battery BMS for Electric Chainsaw

60V 30Ah LiFePO4 Battery with BMS for Electric Lawn Mower Power Tool

15S 48V 100A Master BMS Battery Energy Storage System for Telecom Base Station

Energy BMS for Solar Storage System

100A Lithium-ion BMS System for Data Center

600V Lithium BMS for Smart Grid

Smart Lithium Battery Lifepo4 BMS for Power Station

32s 102.4v 50a Lifepo4 Battery Integrated BMS for Large-scale Energy Storage Cabinet

Built-in 12V 400Ah LiFePO4 BMS for RV Battery

Home Energy StorageBMS Battery Protection Board

16s 18s 19s 20s 21s 24s 72v 80a 120a Lithium Lifepo4 BMS for Golf Car

Waterproof BMS Battery Circuit Board for Elderly Scooter

12v 4s 20a Lifepo4 BMS Board with Balance for E-Motorcycle

7s 24v 150a Liion Bms for E Forklift

20a Li-ion 60v 16s Lithium Battery Pack BMS for E-bike

BMS Battery Management System Embedded in Your E-motor Bike

BMS PCB Board for electric Tractor

BMS Battery protection module PCM for Mine Vehicles

14.8v 4s 10a PCB PCM BMS with Temperature Sensor and Balancing for Smartphone Battery Board

3s 4s 150a BMS Battery Protection Module for Drones

4S 14.8V 16.8V 12A BMS Lithium Battery Protection Board for Laptop battery

4s 14.8v16.8v 20a Li-ion BMS PCM Protection Board for Electric Toys

Battery Protection Board BMS for Electric Street Sweeper

3S 12A 11.1v 12.6V Lithium BMS Protection Module for Electric Vacuum Cleaner

3S 4S 11.1V 14.4V BMS with 3A~10A Lithium Battery PCB Board for Sloar Street Light

3S 4S 8S 15S 16S 12V 24V 48V lifepo4 Battery BMS for Temperature Control Balanced Lamp

60V 300A Lithium BMS Board for Passenger Car

300V 500A Lithium BMS Board for Electric Buses

600V 600A Lithium Battery BMS Board for Electric Trains

12V 40Ah Lifepo4 Battery Pack Balanced BMS for Your Electric Boats

Power Tool

3S 12V Lithium BMS Battery Protection Board for Electric Drill

3S 12V Lithium Battery BMS PCB Board for Electric Screwdriver

4S 16V BMS Lithium Battery Protection Board for Electric Vehicles Garden Tools

12.8V LifePO4 BMS for Solar Generator

21V Lithium Battery BMS for Electric Chainsaw

60V 30Ah LiFePO4 Battery with BMS for Electric Lawn Mower Power Tool

Energy Storage

15S 48V 100A Master BMS Battery Energy Storage System for Telecom Base Station

Energy BMS for Solar Storage System

100A Lithium-ion BMS System for Data Center

600V Lithium BMS for Smart Grid

Smart Lithium Battery Lifepo4 BMS for Power Station

32s 102.4v 50a Lifepo4 Battery Integrated BMS for Large-scale Energy Storage Cabinet

Built-in 12V 400Ah LiFePO4 BMS for RV Battery

Home Energy StorageBMS Battery Protection Board

Light EV

16s 18s 19s 20s 21s 24s 72v 80a 120a Lithium Lifepo4 BMS for Golf Car

Waterproof BMS Battery Circuit Board for Elderly Scooter

12v 4s 20a Lifepo4 BMS Board with Balance for E-Motorcycle

7s 24v 150a Liion Bms for E Forklift

20a Li-ion 60v 16s Lithium Battery Pack BMS for E-bike

BMS Battery Management System Embedded in Your E-motor Bike

BMS PCB Board for electric Tractor

BMS Battery protection module PCM for Mine Vehicles

Consumer Electronics

14.8v 4s 10a PCB PCM BMS with Temperature Sensor and Balancing for Smartphone Battery Board

3s 4s 150a BMS Battery Protection Module for Drones

4S 14.8V 16.8V 12A BMS Lithium Battery Protection Board for Laptop battery

4s 14.8v16.8v 20a Li-ion BMS PCM Protection Board for Electric Toys

Battery Protection Board BMS for Electric Street Sweeper

3S 12A 11.1v 12.6V Lithium BMS Protection Module for Electric Vacuum Cleaner

Public Utilities

3S 4S 11.1V 14.4V BMS with 3A~10A Lithium Battery PCB Board for Sloar Street Light

3S 4S 8S 15S 16S 12V 24V 48V lifepo4 Battery BMS for Temperature Control Balanced Lamp

Automotive

60V 300A Lithium BMS Board for Passenger Car

300V 500A Lithium BMS Board for Electric Buses

600V 600A Lithium Battery BMS Board for Electric Trains

12V 40Ah Lifepo4 Battery Pack Balanced BMS for Your Electric Boats

Industrial

BMS Battery Protection Board As Per Different Categories

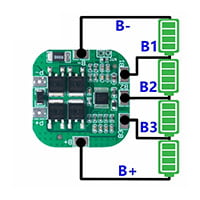

Lithium Battery Protection Board

Perfect for lithium-ion and lithium-polymer batteries, ensuring efficiency and safety in applications like smartphones, laptops, and electric vehicles.

Lead Acid BMS

Ideal for lead-acid batteries, enhancing performance and durability in applications like cars, motorcycles, and backup power systems.

Nickel BMS

Suitable for nickel-cadmium or nickel-metal hydride batteries, regulating current and voltage in applications like toys, cameras, and cordless tools.

BMS for Specialty Chemistry

Customized for uncommon or novel cell chemistries, adapting to specific needs and characteristics in applications like medical devices, military equipment, and renewable energy storage.

Low voltage BMS

Designed for lower voltage systems, typically below 60 volts, include levels such as 6v, 12v, 24v, and 48v. It enhances battery performance in consumer electronics and portable devices.

High Voltage BMS

Tailored for elevated voltage systems from 60V to 1500V , ensuring precision control for large-scale energy storage and industrial equipment.

For battery packs that have a large number of cells connected in series, such as special vehicles or mobile charging cars. Allows flexible configuration and customization.

Low Current BMS

For low-power applications, such as power banks or flashlights. Handles small currents, offers basic functions and protections.

High Current BMS

For high-power applications, such as EVs or ESS. Handles large currents, offers advanced functions and protections.

Centralized BMS

A single central control unit manages all aspects of battery management. Suited for smaller-scale applications, simplifying control and reducing complexity.

Distributed BMS

Multiple independent BMS units manage subsets of battery cells, coordinated by a central controller. Ideal for large battery packs in applications like electric vehicles.

Hybrid BMS

Combines distributed and centralized elements. Multiple BMS units manage modules, supervised and coordinated by a central controller, offering scalability and control balance.

Modular BMS

Flexible and adaptable battery management with a modular design, suitable for diverse system architectures, including distributed, centralized, or custom configurations.

Master-Slave BMS

A master and slaves monitor and control the battery pack. Each slave measures the voltage, current, and temperature of a few cells, while the master handles the computation and communication. Good for high-power applications and flexible energy management.

Parallel BMS

Efficiently manages battery cells/modules connected in parallel configurations, ensuring even distribution of currents. Ideal for applications needing increased capacity or current handling.

Series BMS

Designed for overseeing battery cells/modules connected in series, it maintains balanced voltage and prevents individual cell overcharging or over-discharging. Suited for applications requiring higher overall voltage.

Active Balancing BMS

Employs active components to actively redistribute energy between cells for efficient voltage balance, ideal for energy-efficient applications.

Passive Balancing BMS

Uses passive components to equalize cell voltages during charging, suitable for applications where energy efficiency is less critical.

Hybrid Balancing BMS

Combines passive and active balancing for a balanced approach that optimizes efficiency and effectiveness.

Bluetooth BMS

Allows users to connect directly to the BMS using a Bluetooth-enabled device, such as a smartphone or tablet, for monitoring and control.

IoT Based Battery Management System

Transmit battery data to remote servers or cloud platforms, enabling real-time monitoring, analysis, and control from anywhere with an internet connection.

Cloud Connected BMS

Connects the BMS to a cloud-based virtual BMS for advanced analytics, prediction, and optimization of battery performance.

Key Features of Battery Management System

How Does Battery Management System Work?

Battery monitoring

The BMS constantly monitors the battery pack’s voltage, current, and temperature through sensors connected to the battery pack. It also measures the State of Charge (SOC) of the battery pack.

Battery protection

If any parameter exceeds the safe operating limits, the BMS takes protective action. For example, if the voltage exceeds the maximum limit, the BMS will stop the charging process to prevent overcharging. Similarly, if the temperature exceeds the safe range, the BMS will reduce the charging current to prevent damage to the battery.

Balancing

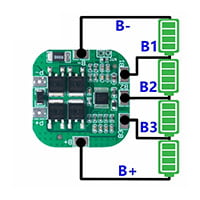

If the BMS detects that the battery pack’s individual cells have different voltages, it uses a balancing circuit to equalize the voltage between the cells, extending the battery pack’s lifespan.

Data communication

The BMS communicates with other systems and devices, such as the vehicle control system, charging system, and other electrical loads. The data exchange enables the BMS to regulate the battery’s charging and discharging current, providing the desired power output for the connected loads.

User interface

Some BMS systems come with a user interface that displays information about the battery pack’s status, such as SOC, battery voltage, temperature, and fault diagnosis codes.

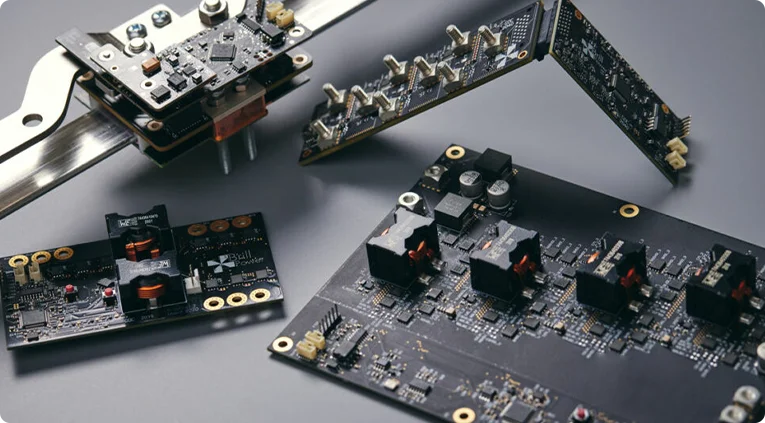

Components of Our Battery BMS System

Not only do we manufacture battery protection boards, but all the electronic components involved in smart BMS battery managemet can be sourced from MOKOEnergy.

-

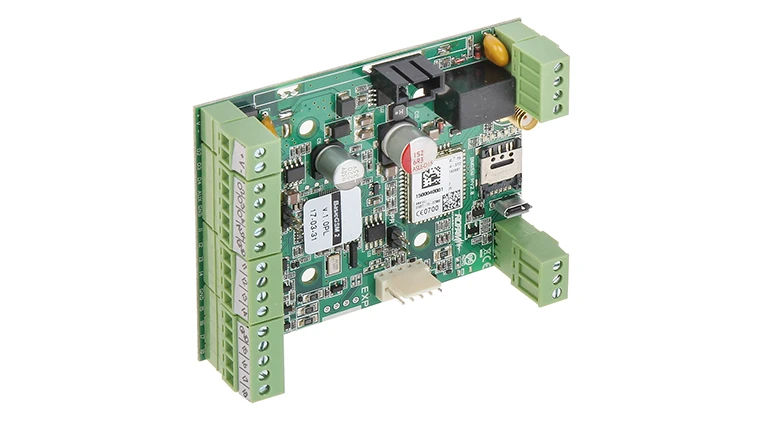

Battery Protection Board

-

Battery Monitor

-

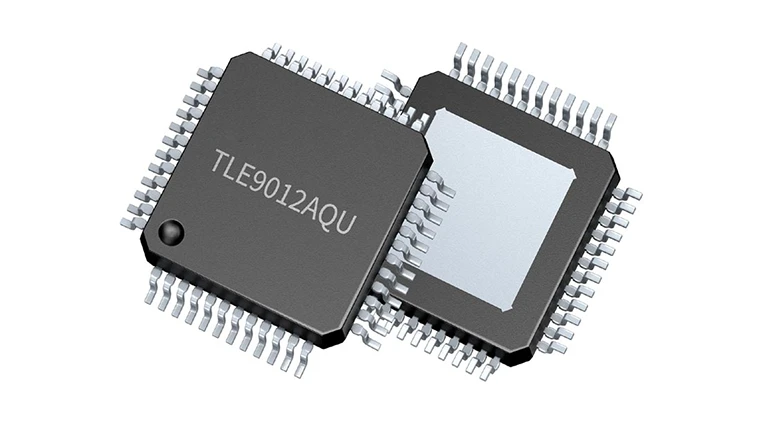

Battery Management ICs

-

Battery Controller

-

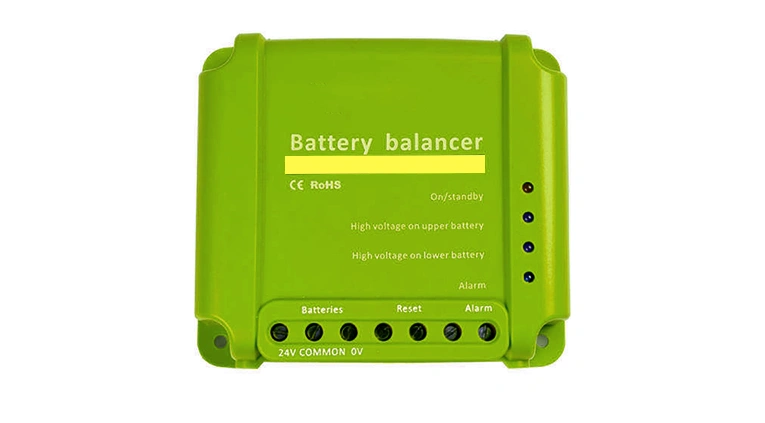

Battery Balancer

-

Communication Module

-

Remote Monitoring System

-

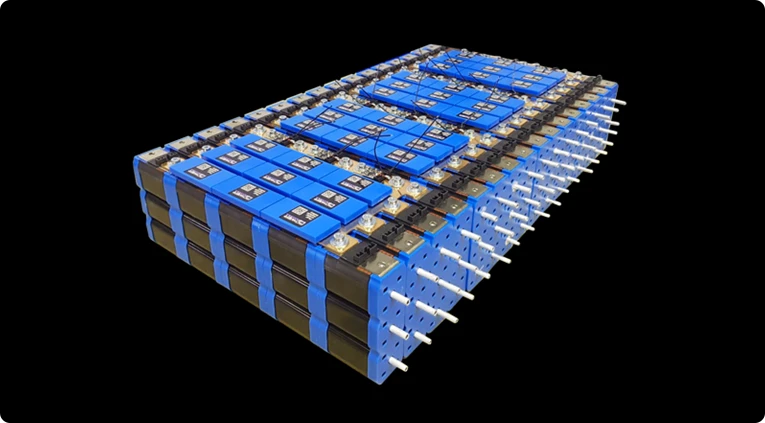

Battery Pack

Also known as the Battery Protection Circuit Module(PCM), is the core component of the battery management system, used to monitor and protect the battery, prevent over-charge, over-discharge, short circuits and other faults.

Used to monitor battery voltage, current, temperature, SOC and SOH, and then feedback to the BMS controller in real-time to help the controller make correct control and protection decisions.

Monitor battery voltage, current, temperature and other parameters, and transmit these parameters to the central processing unit.

Used to control battery charging and discharging, which can be achieved by controlling the charger and discharger.

This device balances the capacity of battery packs by transferring charge from batteries with a high voltage to batteries with a low voltage.

Transmit data from the BMS to electric vehicles or other devices, and receive instructions from these devices.

Remotely monitors and controls the battery management system over the Internet to discover battery faults and anomalies in time, ensuring battery safety and reliability.

Supply power, such as lithium batteries or supercapacitors, to ensure the normal operation of the BMS system.

Why Choose MOKOEnergy BMS

Modularity & Scalability

Any number of battery cells can be connected in series or parallel.

Compatibility

Compatible with any lithium-ion cell type and format

Custom Solution

Offer a combination of stability, agility, and flexibility as per customers’ requirements.

Series Connection

The maximum series connection can be up to 32 series.

Performance

In-depth knowledge of BMS host applications and features, design optimization for manufacturability, DFM, DFT, reliability, and TCO.

Turnkey BMS Solution

Offers one-stop services including OEM, ODM, and DFM services as a turnkey supplier of BMS design, integration, components, assembly, and testing.

Quality

Proprietary ATE, integrated programming, calibration, and functional testing. Comply with CGP/ITAR and other certifications.

Time-to-Market

Reduce time to market by leveraging an existing portfolio of mature and highly engineered BMS solutions.

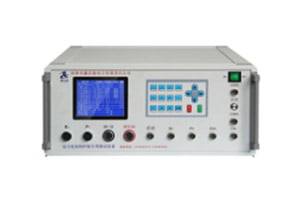

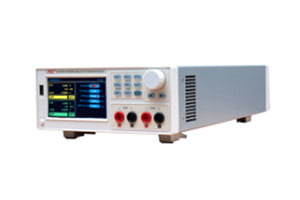

Each BMS Board is 100% Tested with Automatic Tester

Our All-in-one Service

Fully integrated R&D, design, supply chain, manufacturing, automated testing, and applications support.

PCB Design & Manufacturing

Provides PCB board design and manufacturing services as an OEM, ODM and DFM manufac-turer to ensure the reliability and performance of BMS.

Component Procurement

Help customers to purchase the components required by BMS, including chips, resistors, capacitors, etc.

Assembly

Our services include PCB assembly, component assembly and welding for our customers.

Software Development

Software is provided to monitor and control the status of the battery to ensure the performance and stability of the BMS.

Mechanical Engineering

Provides CAD/CAM,CNC,3D printing, Molding, and Enclosure manufacturing.

Experimental Testing

Provide testing services such as debugging, rework, in-house testing, high and low-temp-erature testing, temperature humidity testing and EMI testing.

Quality Control

Perform functional testing and certification for each component of BMS, including AQL inspection, ISO9001:2015, ISO13485, ROHS, UL, CE, FCC, RoHS, etc.

Packaging and Logistics management

Help customers to manage BMS logistics, including material purchase, inventory manage-ment, transportation, and delivery.

Customer Service

Provide timely technical support and customer service to solve customers' questions and other needs regarding BMS products.

FAQs of BMS Battery Management System

A Battery Management System (BMS) is an electronic system that monitors and manages the charging and discharging of batteries. It helps to extend the life of the battery, prevent overcharging and undercharging and ensures safe and efficient operation.

The main components of a smart battery management system include a microcontroller, sensors, relays, battery balancers, and communication interfaces.

A BMS battery management solution can manage various types of batteries, including lead-acid, lithium-ion, nickel-cadmium, and nickel-metal-hydride.

Yes, a BMS can communicate with other devices, such as chargers, inverters, and monitoring systems, using various communication interfaces like CAN, RS232, or Bluetooth.

The calibration frequency of a Battery management system depends on the manufacturer’s recommendation and the application. In general, it is recommended to calibrate a BMS every six months to maintain its accuracy and reliability.

Some common BMS faults include incorrect battery voltage readings, overcurrent protection faults, communication errors, and temperature sensor failures.

There are several communication types for smart battery management system, including CAN bus, Modbus, Ethernet, and Wi-Fi.

Yes, a BMS can help improve battery performance by ensuring that the battery is charged and discharged at the correct rate and preventing overcharging and overheating.

The lifespan of a smart BMS system depends on several factors, including the quality of the components and the frequency of use. On average, a battery BMS system can last between 5-10 years.

It depends on the application. For small-scale applications with only one or two batteries, a BMS may not be necessary. However, for larger-scale applications with multiple batteries, a BMS is recommended for safe and efficient operation.

Yes, a BMS battery management system can help prevent battery fires by monitoring the battery’s temperature and preventing it from overheating.

Based on the Topology, the battery management system can be classified into Centralized BMS Architecture, Modular BMS Topology, Primary/Subordinate BMS, and Distributed BMS Architecture