Cell balancing in BMS is essential for maximizing the potential of modern energy storage devices like batteries, enabling us to live life to the fullest by providing reliable power even during overwhelming and non-ending situations, such as a quarter meeting without a power supply. The remarkable science of Battery Management Systems (BMS) serves as the kernel of battery operations, ensuring output checks and protecting against external damages. BMS functions encompass temperature monitoring, preventive arrangements, forecasting, and data collection through battery parameter analysis. When a battery comprises sequential cells in series, proper cell balancing becomes crucial to maintain its life cycle, optimize performance, and ensure high efficiency. In this article, we’ll explore more details of cell balancing in battery management systems so that you will know whether you need a balanced BMS.

What is Cell Balancing?

Cell balancing in BMS, also known as cell balancing lithium-ion battery redistribution, plays a vital role in improving the overall potential and longevity of battery packs while enhancing each cell’s State of Charge (SOC). Imbalances arise when individual cells within the battery pack exhibit varying SOC, causing the overall battery capacity to be limited by the weakest cell. To optimize battery life, cell balancing becomes crucial to equalize each cell’s charge within the pack. In the realm of Battery Management Systems (BMS), two primary cell balancing techniques are employed, and we will explore them in detail.

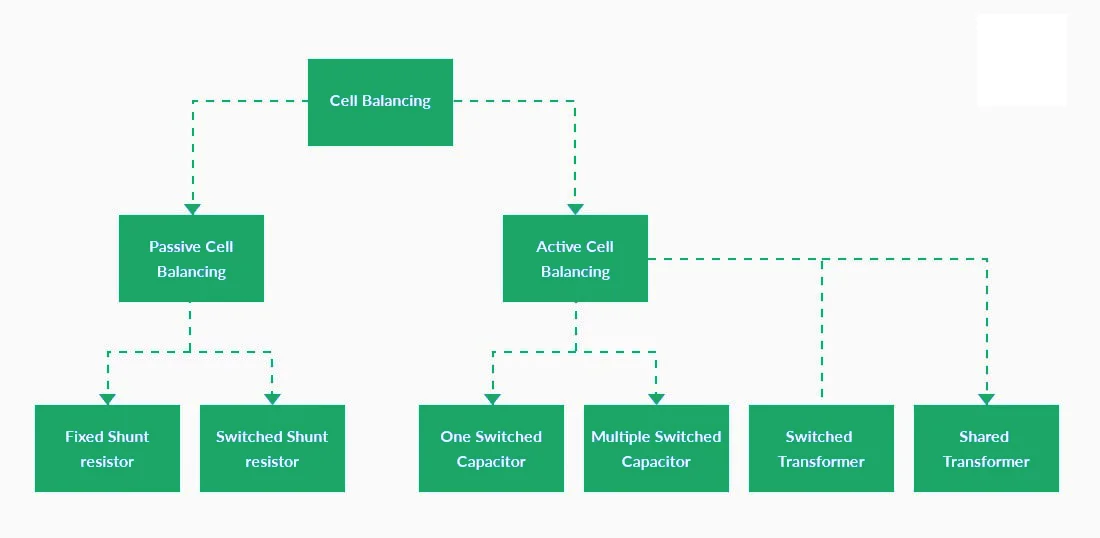

Types of Cell Balancing Techniques

Active Cell Balancing

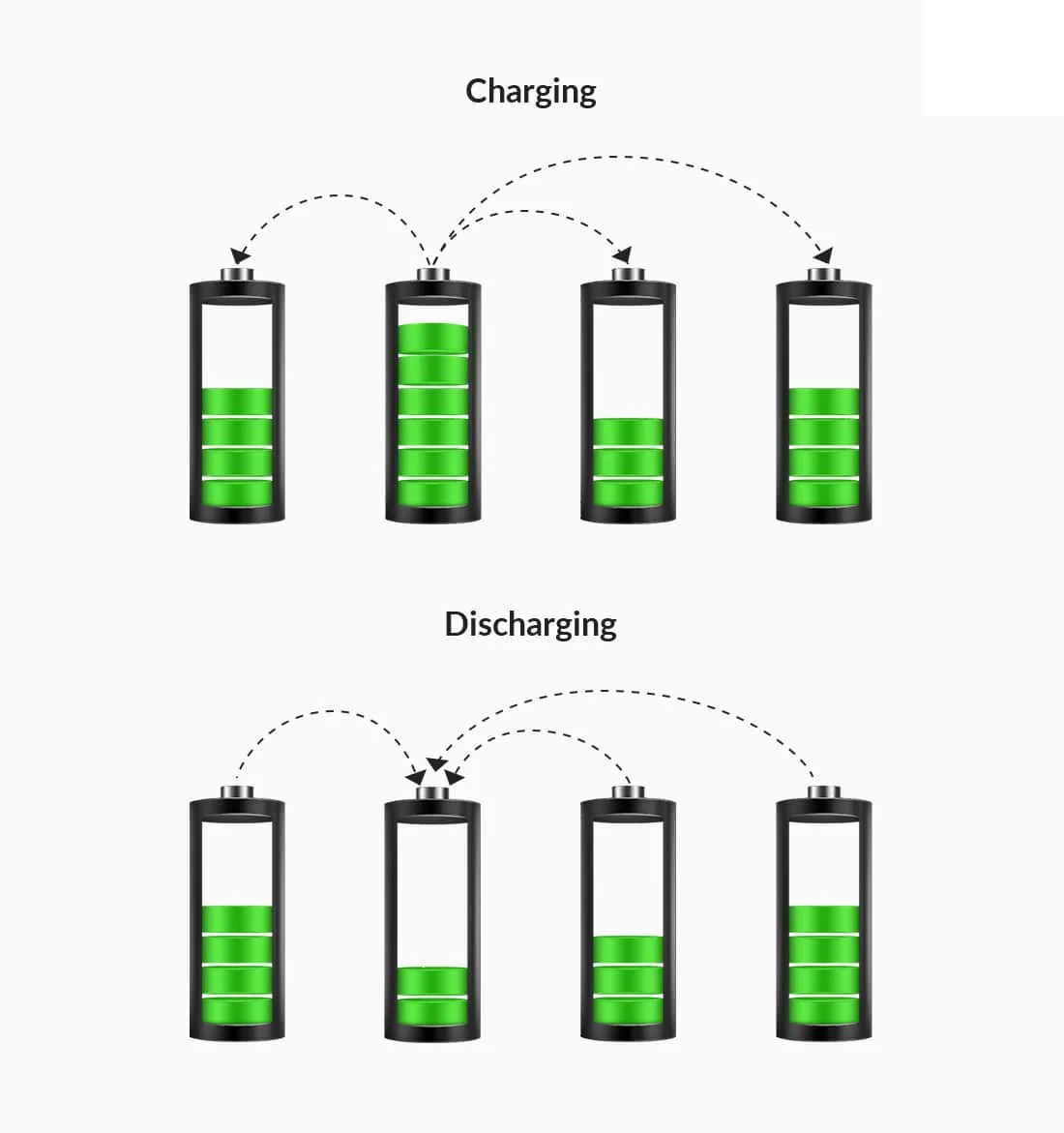

In active cell balancing in BMS, energy moves from cells with higher voltage to those with lower voltage within the battery. This process actively ensures that the battery with a higher state of charge (SoC) transfers its energy to the battery with a lower state of charge, effectively preventing the loss of heat energy. Instead, active balancing BMS employs shuttling or converters to equalize the energy levels between the highest and lowest voltage cells.

Charge shuttling facilitates the transfer of charges to achieve balanced cell voltage, while energy converters use transformers and conductors to transfer energy. This advanced battery balancing method optimizes battery performance, promoting efficiency and extending cell life.

Advantages of Active Cell Balancing

- BMS with active balancing proves highly effective, especially when dealing with batteries comprising cells of varying capacities.

- It enhances battery energy efficiency by effectively reserving and retaining excess energy.

- The implementation of active cell balancing BMS contributes to a longer life expectancy for individual cells.

- This technique stands out for its swift cell balancing process, optimizing battery performance promptly.

Disadvantages of Active Cell Balancing

- When energy is transferred between cells, there is a large loss of energy, usually between 10% and 20%.

- Active cell balancing only facilitates a one-way flow of energy, moving solely from higher to lower voltage cells.

- The complexity of the control algorithm and the need for a power electronics interface result in higher production costs for active cell balancing.

Passive Cell Balancing

Passive cell balancing in BMS or passive balancing BMS involves the dissipation of excess energy from higher energy cells until they align with or equal the voltage of the lower voltage cell. This technique employs either fixed shunting or switching shunting resistor methods for achieving balance within passive cell balancers.

Advantages of Passive Cell Balancing

- Passive Cell Balancing eliminates the need to balance a well-functioning battery pack.

- This technique ensures no unnecessary energy wastage when the battery is balanced.

- All cells are maintained at the same State of Charge, promoting uniformity and efficiency.

- It is a cost-effective method for cell balancing, making it an economical choice.

- Passive Cell Balancing offers self-discharging current and addresses long-term mismatches, enhancing battery performance.

Disadvantages of Passive Cell Balancing

- Passive Cell Balancing exhibits low thermal management capabilities, potentially impacting battery temperature control.

- When the State of Charge is full, this technique does not provide further balancing.

- The method only balances the top 95% of each cell by burning off excess energy, leaving a slight imbalance in the remaining 5%.

- Passive Cell Balancing results in a considerable amount of energy loss, leading to decreased transmission efficiency.

- This technique does not contribute to improvements in battery run time, limiting overall battery performance enhancements.

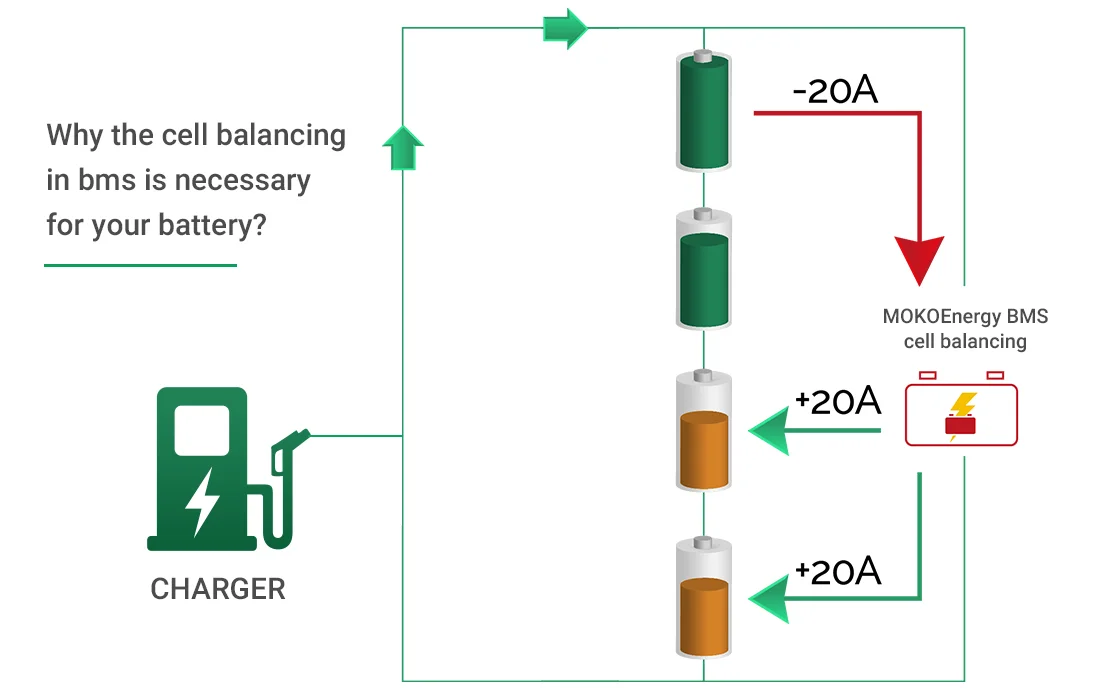

How BMS Cell Balancing Works

Cell balancing in the MOKOEnergy BMS takes place during the CHARGE mode, powered by pin 3 on the Main I/O connector. Once any cell exceeds the Start Balancing voltage, the BMS initiates the balancing algorithm for all cells. It applies a load to cells with voltages above the lowest cell’s maximum difference, bringing them into balance. This continues until all cells are within the defined voltage difference, even after the charger is off.

To ensure safety, the BMS incorporates a protective feature against over-discharging when a defective or dead cell is present. It employs a minimum balancing voltage threshold to safeguard cells from over-discharge and prevent any potential race conditions where the BMS might remove the charge from alternating cells.

Start balancing voltage should be set around 5-10% of the maximum state of charge, with a recommended maximum voltage difference of 10mV between cells for most lithium-ion chemistries. The minimum balancing voltage setting must be below the settling voltage to allow effective balancing.

During balancing, the BMS pauses periodically to allow cell voltages to settle and re-evaluate balance. Longer pauses occur at elevated temperatures to prevent overheating. Balancing ceases when the heatsink temperature exceeds 50°C to avoid burn hazards.

Cell Balancing Algorithms

Cell balancing employs two primary algorithms:

Voltage-based balancing

In voltage-based cell balancing, the focus is on comparing and confirming the equality of voltage levels among cells. If any discrepancies are detected, cell balancing is triggered through this method.

History-based balancing

In history-based cell balancing, the state of charge (SoC) serves as the reference point. The algorithm assesses the difference in cell charges (available) and activates cell balancing when the difference exceeds a predefined threshold, usually set at 1.

Why do we need BMS Cell Balancing?

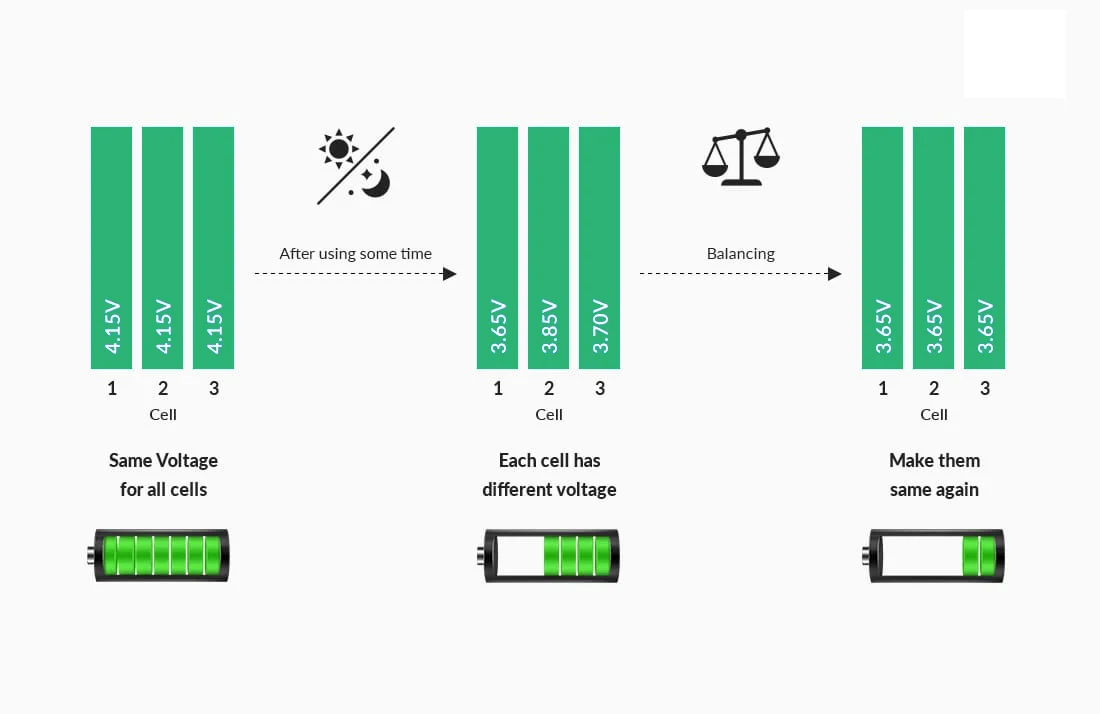

Cell balancing is a crucial technique that ensures the voltage levels of individual cells in a battery pack connected in series remain equal, thereby maximizing the battery pack’s efficiency. While assembling the battery pack, cells are carefully selected for the same chemistry and voltage value. Yet, as the charging and discharging processes unfold, cells experience voltage variations due to a myriad of factors, resulting in cell unbalancing, which subsequently leads to several challenges.

Thermal Runaway

A critical concern is thermal runaway, where overcharging and over-discharging of lithium cells can lead to hazardous situations. To illustrate this, consider a four-battery pack where one cell reads 3.5V while the others display 3.2V. During charging, they are treated as a series, leading to excessive charging of the 3.5V cell beyond the recommended voltage threshold.

Cell Degradation

To illustrate this, consider a four-battery pack where one cell reads 3.5V while the others display 3.2V.

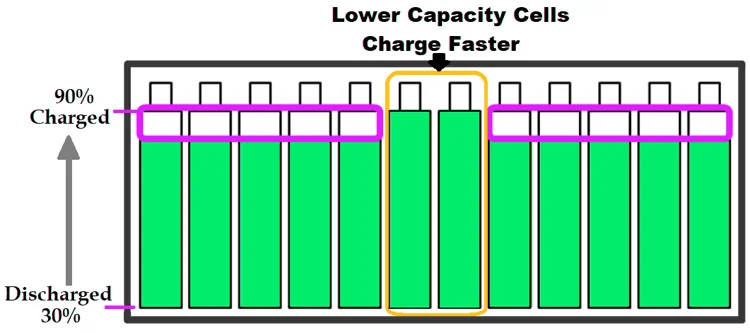

Incomplete charging of Pack

Over time, some cells in the pack may weaken compared to their neighbors, leading to faster charging and discharging. As cells charge in series, if one cell reaches the maximum voltage, the charging process stops, leaving weaker cells partially charged.

Incomplete use of Pack energy

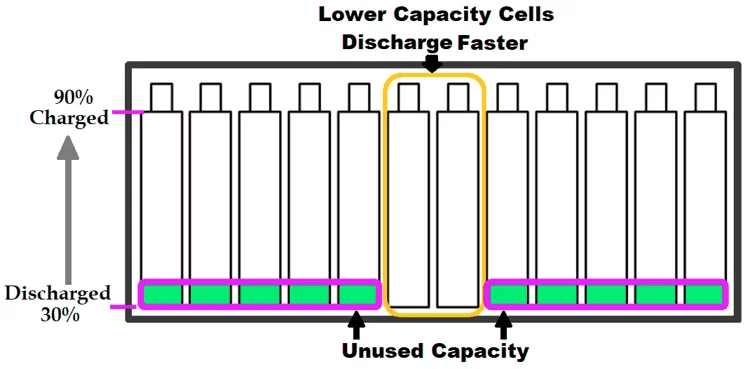

During discharge, weaker cells deplete faster than healthy cells, reaching the minimum voltage prematurely. This results in unused capacity in the battery pack.

Incomplete Charging of Battery Packs

Considering these potential disadvantages, cell balancing becomes imperative to maximize the battery pack’s efficiency. While in certain low-cost applications with no battery replacement concerns, cell balancing may be omitted, in most cases, such as electric vehicles, cell balancing is indispensable to optimize the battery pack’s performance.

What causes Cell unbalancing in battery packs?

Ensuring cell balance within a battery pack is crucial, but understanding why cells become unbalanced is essential to address the issue effectively. When initially assembling a battery pack by placing cells in series, efforts are made to ensure their voltage levels are the same, resulting in balanced cells. However, during usage, cells can become unbalanced due to various reasons.

SOC Imbalance:

Measuring the State of Charge (SOC) of individual cells is complex, making it challenging to match cells based on SOC instead of just voltage levels during pack assembly. Due to these variations in State of Charge (SOC), the Open Circuit Voltage (OCV) may undergo changes over time.

Internal resistance variation:

Finding cells with identical Internal Resistance (IR) is difficult, and as the battery ages, the IR of cells can change, resulting in some cells having different IR values. This variance affects the current flow through cells and, consequently, their voltages.

Temperature:

Cell charging and discharging capacities are influenced by the surrounding temperature. In large battery packs like those in EVs or solar arrays, cells may experience temperature differences, causing one cell to charge or discharge faster than others, leading to imbalances.

Given the above reasons, preventing cell imbalance during operation is challenging. The solution lies in using an external system called the Battery Balancing System. Numerous hardware and software techniques are employed for battery cell balancing, each with its unique advantages. Let’s explore the different types and widely used techniques.

Precautions of Battery Balance

During the charging balancing process, certain considerations need attention:

Ensure periodic stops in charging to measure battery voltage accurately and facilitate the balancing process.

Beware of voltage glitches caused by voltage conversion and inductive resonance of the charger, as they can lead to measurement errors.

Use an external power transistor with low on-resistance during charging.

When performing a discharge balance on the battery, the following points should be noted: During the discharge balance process, there is expected to be a certain amount of power consumption. Additionally, be mindful that unused power will be consumed during this phase of balancing. Recognize that balancing the battery during discharge may take longer due to the influence of resistance on discharge speed, resulting in lower balancing efficiency.

To achieve a shorter balancing time, employ an external power transistor with a smaller on-resistance.

If using a resistor with low resistance, a high-power device is necessary.

Conclusion

In conclusion, cell balancing in BMS plays a pivotal role in optimizing the efficiency and performance of battery packs, ensuring a reliable power supply during critical situations. With the remarkable science of Battery Management Systems acting as the kernel of battery operations, MOKOEnergy excels in delivering cutting-edge solutions that cater to the evolving needs of energy storage. Their team of expert engineers leads the industry in cell balancing techniques, providing tailor-made BMS solutions and lithium cell balancers that maximize battery life and promote sustainable energy practices.

MOKOEnergy’s commitment to excellence, quality, and innovation positions them as a leading player in the energy storage industry. Whether it’s for electric vehicles, renewable energy storage systems, or vital backup power applications, MOKOEnergy’s BMS solutions stand as a testament to their dedication to a greener and more sustainable future. With MOKOEnergy as your trusted partner, you can unleash the full potential of your battery packs and embrace a future powered by efficient and eco-friendly energy storage solutions. Contact us and our expert will answer all questions about your BMS project!