The Safe Operating Area (SOA) of a battery is a critical concept that defines the operational limits within which a battery can function safely and reliably. It encompasses a range of parameters, including voltage, current, temperature, and environmental conditions, that, if exceeded, may compromise the integrity, performance, and safety of the battery. In this guide, we will delve into the key aspects of battery operation, outlining the specific parameters that define the battery SOA. By understanding and implementing best practices for battery management within these parameters, users can ensure the safe and efficient operation of their battery systems.

What is Battery SOA (Safe Operation Area)?

Safe Operating Area (SOA) refers to the defined range of voltage, current, and temperature conditions within which a battery can operate without sustaining damage. In the context of a Battery Management System (BMS), the primary objective is to guarantee the safe operation of a battery pack. Detecting and preventing thermal runaway is crucial to avoiding potential mishaps. The BMS plays a pivotal role by continuously monitoring various battery parameters, optimizing power usage based on the gathered data, and simultaneously ensuring the safety of the battery pack. The SOA is a critical concept, establishing the permissible limits for voltage, current, and temperature, and the BMS utilizes this information to safeguard the battery pack by identifying and addressing issues such as overheating and implementing effective thermal management strategies.

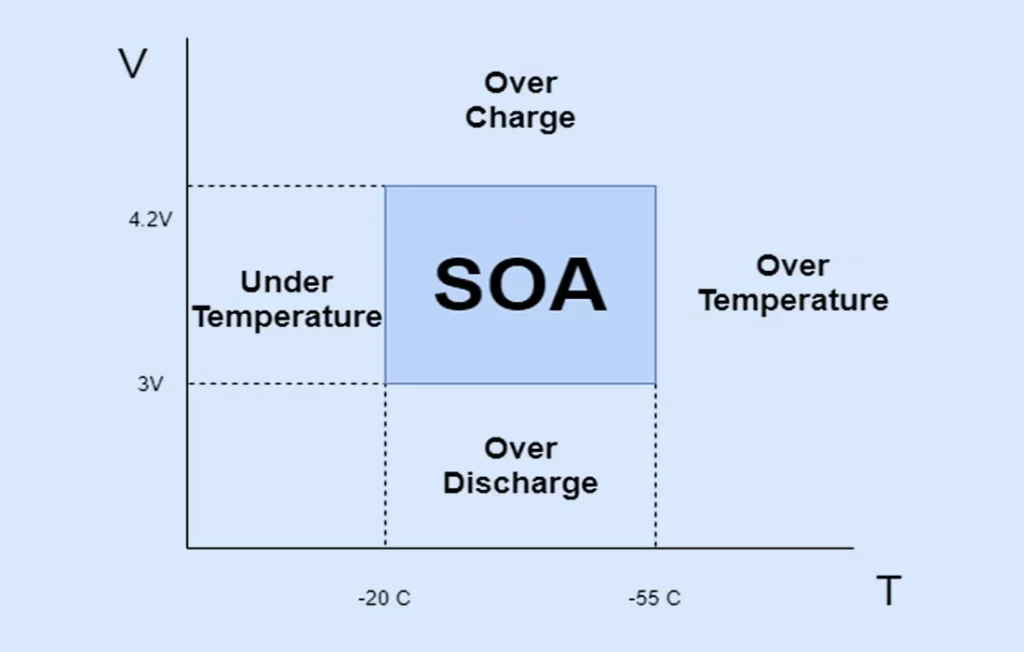

The battery SOA for Li-ion cells is determined by considering the operational range in terms of temperature, voltage, and current. In the case of Li-ion cells, the acceptable operating temperature spans from -20℃ to 60℃, and the safe operating voltage typically ranges from just below 2V to approximately 4V. Charging/discharging current rates for most Li-ion cells typically fall within the range of 0C to 20C, contingent on battery chemistry. It is noteworthy that discharging current limits often exceed the corresponding charging limits. However, these charging/discharging rates are also constrained by the operating temperature.

The depiction of the SOA primarily involves delineating boundaries based on temperature and voltage. Deviations from the specified voltage boundaries—either too high or too low—can result in degradation, such as dendrite formation and anode dissolution. Elevated temperatures may lead to battery breakdown, heat release, and eventual thermal runaway, while excessively low temperatures can induce cathode damage, short circuits, or lithium plating.

Therefore, to ensure the batteries are operating within SOA, there are 3 key protections are needed: overcharge and over-discharge protection, over-current protection, and temperature protection.

3 Protection Methods To Ensure Safe Operation Within SOA

Overcharge/Discharge Safeguard

- Potential Impacts

- Li-ion cells face rapid deterioration and the risk of ignition when subjected to overcharging beyond specified voltage thresholds.

- Most Li-ion cells are susceptible to damage when charged or discharged beyond designated voltage limits.

- Protective Measures

- Safeguard against cell voltage dropping below a set limit by halting discharge currents or prompting a cessation.

- Mitigate the risk of cell voltage surpassing prescribed limits by halting charge currents, ensuring the safety of all Li-ion cells.

Overcurrent Protection

- Potential Implications

- The lifespan of Li-ion cells diminishes when subjected to very high discharge currents or excessively rapid charging.

- Li-ion cells can sustain damage if exposed to high pulsed currents for extended periods.

- Safeguard Measures

- Restrict charge currents from surpassing predefined limits, considering cell voltage, temperature, and prior current, either by reducing the current or halting it directly.

- Ensure discharge currents do not exceed specified limits, employing the protective strategy outlined above.

Temperature Protection

- Potential Outcomes

- Drastic reduction in lifespan if Li-ion cells are discharged beyond a certain temperature range or charged outside an even narrower temperature span.

- Risk of thermal runaway and ignition if cells surpass a safe temperature threshold.

- Protective Measures

- Proactively prevent a cell’s temperature from surpassing a defined limit by directly halting battery currents, requesting cessation, or initiating cooling measures.

Key Parameters of SOA

Understanding the following fundamental parameters of battery safe operating area is essential.

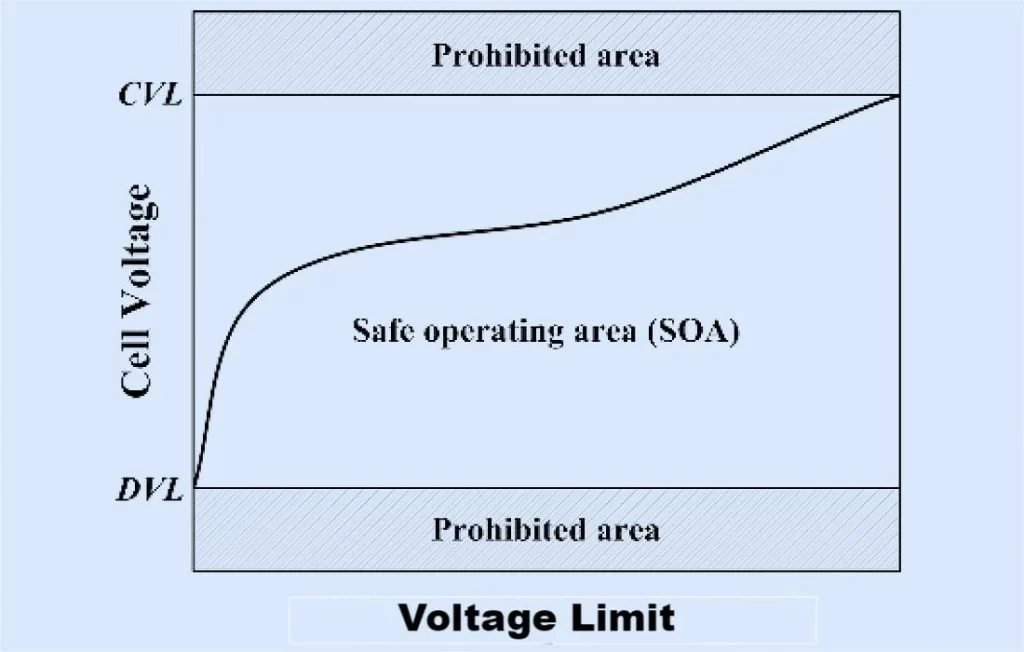

Voltage Limits

The voltage of a lithium-ion cell must be kept within specified limits to avoid damage. The maximum voltage is typically around 4.2V. Exceeding this can cause plating of metallic lithium, electrolyte decomposition, and other issues. The minimum voltage is around 2.5-3.0V. Discharging below this threshold can lead to copper dissolution, active material loss, and capacity fade. Staying within the upper and lower voltage limits is critical for safe operation and longevity.

Current Limits

Like voltage, battery current must also be constrained. The maximum discharge current relates to heating and power capability. Drawing too much current can lead to overheating. Cells are rated for a certain continuous and peak discharge current. The maximum charge current is also important. Too high of a charging current risks lithium plating, especially at low states of charge. Most lithium-ion batteries have a specified maximum charge current, often around 1C (the current to fully charge in 1 hour).

Temperature Limits

Lithium-ion batteries perform best within a moderate temperature range, typically 0°C to 45°C. Operation outside this window can impair performance and accelerate aging. Cooling systems like air or liquid cooling help regulate temperature during operation. Heating systems preheat cells prior to charging in cold environments. Staying within the operating temperature range helps maximize service life.

Environmental Factors

Moisture, dust, and other contaminants can degrade lithium-ion batteries over time. High humidity facilitates corrosion and dendrite growth. A sealed enclosure protects cells from dirt, debris, and splashing water. Periodic inspections check for any signs of physical damage or moisture ingress. Careful consideration of the operating environment is key to ensuring optimal battery life and performance.

Importance of Understanding and Maintaining SOA

- Safety: Operating a battery outside its designated SOA can lead to hazardous conditions, such as overheating, chemical reactions, and even the risk of fire or explosion. Adhering to the SOA is crucial for preventing accidents and ensuring the well-being of both individuals and the surrounding environment.

- Performance: Staying within the specified SOA promotes optimal performance and efficiency. Deviating from these guidelines may result in a decline in battery capacity, increased internal resistance, and a shortened overall lifespan.

- Reliability: By operating a battery within its designated SOA, users can maintain the reliability of their energy storage systems. This is particularly significant in applications where consistent and dependable power is essential, such as medical devices, telecommunications, and critical infrastructure.

- Cost Efficiency: Adhering to the SOA helps avoid premature wear and tear, reducing the need for frequent replacements and minimizing overall operational costs. This is especially pertinent in large-scale applications where battery replacements can be a significant financial burden.