In the field of energy storage, Battery Management Systems (BMS) play a pivotal role in ensuring the optimal performance and longevity of batteries. These sophisticated electronic systems are designed to monitor, control, and protect battery packs, but like any technology, they are not immune to challenges. As battery technology continues to evolve, so do the complexities associated with BMS. In this blog, we will embark on common BMS problems that users encounter and provide practical troubleshooting tips. Whether you are a seasoned professional in the energy storage industry or a curious enthusiast looking to understand more about BMS, join us as we explore the common issues that can arise and unravel the solutions that will keep your battery systems running smoothly.

What is BMS?

Battery Management System plays a critical role in regulating and protecting batteries across a wide range of applications from electric vehicles to consumer electronics. At their core, they monitor key parameters and control how energy flows in and out of the battery.

By continually tracking voltage, current, temperature changes, and other metrics, a BMS can prevent issues like overcharging, deep discharging, and operating outside safe temperature ranges – all of which can cause permanent battery damage over time. Beyond protection, an optimized BMS works to actively improve battery performance and extend its usable lifespan.

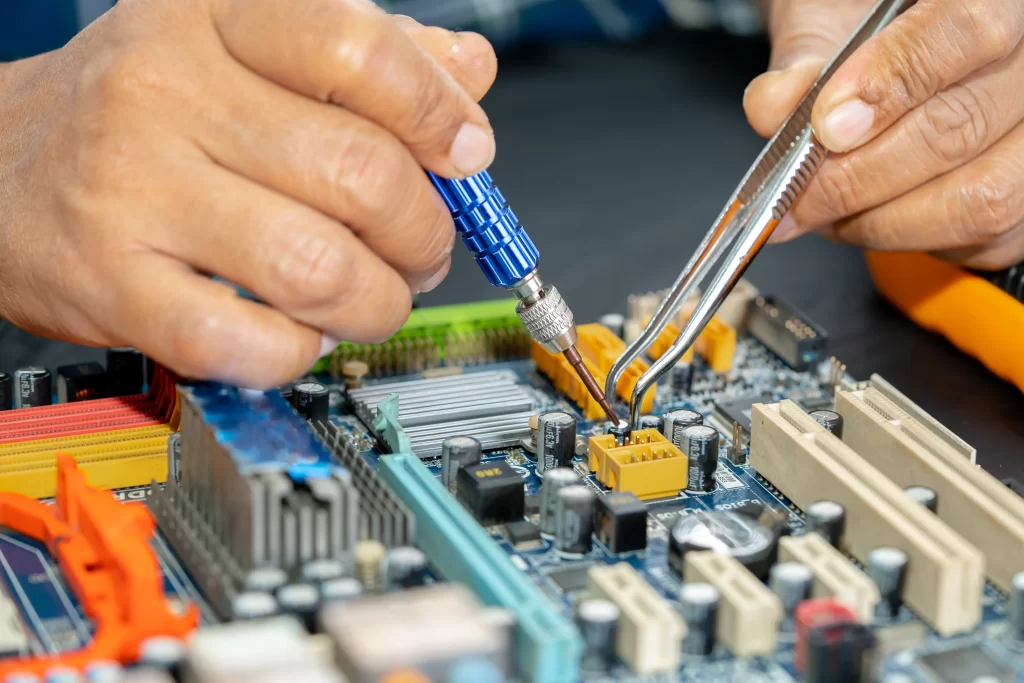

Maintaining a robust, reliable BMS requires care across both its hardware and software components. Circuit boards, sensors, and communication protocols enable data collection and analysis, while control algorithms and programming determine the appropriate charge/discharge rates and safety boundaries. As with any complex system, regular checkups and maintenance are advised to catch any emerging issues early.

When cared for properly, the BMS operates seamlessly in the background to keep the battery safe and performing at its peak. As batteries continue to power more and more aspects of both personal and industrial technology, the role of intelligent Battery Management Systems will only increase in importance.

Common BMS Problems and Causes

Following is an overview of common BMS problems along with their potential causes.

| Common BMS Problems | Causes |

| Voltage Imbalance | 1. Cell variations in capacity 2. Aging or damaged cells 3. Faulty cell monitoring circuits 4. Poor cell balancing algorithm implementation |

| Overcharging/Overdischarging | 1. Inaccurate voltage sensing 2. Faulty charge/discharge control algorithms 3. BMS calibration issues 4. External factors affecting charging/discharging |

| Thermal Management Issues | 1. Inadequate cooling system 2. Poor thermal sensor calibration 3. Overly aggressive temperature control settings 4. Insufficient heat dissipation measures |

| Communication Failures | 1. Faulty communication lines 2. Incompatible communication protocols 3. BMS software glitches 4. EMC (Electromagnetic Compatibility) interference |

| Capacity Loss | 1. Cell aging and degradation 2. Inconsistent charging/discharging cycles 3. Incorrect state-of-charge estimation 4. Lack of proper maintenance |

| False Alarms | 1. Sensor malfunctions 2. Inadequate threshold settings 3. BMS software bugs 4. External electromagnetic interference |

Voltage Imbalance

Individual cells within a battery pack can become unbalanced over time, meaning some cells become overcharged while others become undercharged. This occurs because there are always slight differences between cells in terms of their self-discharge rates, internal resistances, capacities, and operating temperatures. The result is that some cells end up drifting above or below the average voltage. Out-of-balance cells reduce the overall usable capacity of the battery and can lead to both premature cell aging as well as overcharge or undercharge damage. An effective BMS must have precise monitoring and cell balancing capabilities to measure voltage differences and keep cells locked in at the proper levels. Both passive and active balancing techniques may be incorporated, but the algorithms must be robust enough to respond to real-world operating conditions across long periods.

Overcharging/Over discharging

Overcharging happens when a battery is charged beyond its recommended voltage, while over-discharging occurs when the battery is depleted below its safe voltage limit. It there are problems like malfunctioning charging systems, inaccurate voltage monitoring, or user errors in handling the battery, it may cause overcharging or over-discharging. Both scenarios can lead to irreversible damage, reduced capacity, and safety hazards. Also, it will reduce battery life, increase heat generation, potential electrolyte breakdown, and in extreme cases, thermal runaway or cell rupture.

Thermal Management Issues

Lithium-ion batteries use flammable electrolytes that can decompose and release heat if a cell is breached or critically overcharged. This heat can spiral into thermal runaway if adjacent cells also start failing. Besides direct damage, high operating temperatures also accelerate cell aging even without reaching runaway levels. BMS systems must incorporate thermal sensors and the ability to modulate or cut off charge/discharge current to keep cells in a safe temperature window.

Communication Failures

In larger battery systems, monitoring and control electronics are distributed across many PCB assemblies rather than a single centralized BMS computer. This means vital measurement, safety, and battery health data must be continuously synchronized across multiple microcontroller nodes. Any communication failures between these nodes can cripple the BMS, preventing proper cell voltage assessments and the triggering of protective responses when out-of-bounds conditions occur.

Capacity Loss

Factors like cycling, high temperatures, and prolonging high/low state of charge all contribute to lower usable pack capacity over time. BMS tracks capacity fade and provide SOH estimations to notify of diminishing run times.

False Alarms

Battery management systems often rely on voltage, current, and temperature alarm thresholds to catch potentially hazardous cell conditions before they escalate into catastrophic events. However, incorrect sensor readings or overly tight alarm limits can lead to false positive triggers that reduce system availability through unnecessary power cutoffs, contactor openings, or alerts during benign operating conditions. Battery management engineers must select reliable sensor components across expected environmental conditions and then apply filtering and analytics to avoid false alarms. System diagnostics should also clearly differentiate between valid critical events versus mere sensor glitches or excessive conservatism.

How to Prevent and Solve These BMS Problems?

Troubleshooting Strategies

Maintenance and troubleshooting for Battery Management Systems (BMS) require a holistic approach to ensure the reliability and longevity of energy storage systems. Regular inspections and testing are foundational elements, allowing for the identification of potential issues before they escalate. Routine checks should encompass all components, including wiring, sensors, and communication pathways, with diagnostic tools used to conduct comprehensive testing on key parameters like voltage and temperature. Software updates are crucial for addressing bugs and maintaining compatibility with evolving technologies, while sensor calibration ensures the accuracy of monitoring equipment. Implementing cell balancing techniques and capacity testing helps monitor the health of individual cells, addressing voltage imbalances and capacity issues before they impact overall system performance. Proper functioning of temperature control systems, including cooling and heating mechanisms, is essential to prevent overheating, requiring regular inspections and cleaning of cooling components. Robust communication pathways are maintained through regular testing, redundancy, and backup systems to ensure reliable data exchange between BMS components. Additionally, user education on proper battery handling and operational guidelines, coupled with emergency response plans, further contributes to system resilience. Swift responses to issues, guided by a well-established emergency response plan, help mitigate risks and enhance overall system reliability.

Maintenance Strategies

In troubleshooting scenarios, a systematic approach involves investigating false alarms, irregular readings, or communication failures. This includes checking for outdated software, recalibrating sensors, and inspecting wiring and communication hardware. When addressing voltage imbalances or capacity issues, a thorough analysis of individual cells may be necessary, leading to actions such as cell balancing or replacements. Thermal management issues require an inspection of cooling components, ventilation systems, and temperature sensors, followed by corrective measures like repairs or replacements. User errors can be mitigated through ongoing education and training programs, ensuring adherence to recommended procedures for charging, discharging, and overall battery usage.

Ultimately, a proactive stance, combining regular maintenance with effective troubleshooting strategies, is essential for sustaining the reliability and optimal performance of Battery Management Systems in various energy storage applications.

Conclusion

Grasping common battery management system failure issues and their remedies is fundamental for those interacting with batteries. Pinpointing the roots of malfunctions allows sidestepping disasters and upholding critical safety steps when handling batteries. Above all, proactive prevention spares one from subsequently addressing a prospective catastrophe.

MOKOEnergy is an experienced manufacturer of battery management systems (BMS) for energy storage applications across industries. We understand that having a reliable BMS is crucial for systems that use batteries, especially in safety-critical situations like electric vehicles and medical devices. Our BMS solutions are designed to maximize battery safety, lifetime, and performance. We use advanced algorithms to continuously monitor parameters like cell voltage, current, and temperature, allowing for early detection and prevention of issues like over-charging, over-discharging, and overheating. With deep BMS technology expertise built over years, MOKOEnergy provides customized solutions tailored to the specific needs of the application. We also offer comprehensive support across the product lifecycle – from design, testing, and production to maintenance. Contact us to learn how our advanced BMS can unlock the full potential of your battery-powered systems safely and reliably.