In our technology-driven world, batteries power essential devices and systems. Battery management systems (BMS) play a crucial role in optimizing battery performance and safety. It continuously monitors and safeguards batteries, enhancing efficiency and prolonging lifespan. BMS topologies, and different configurations of BMS components, offer unique advantages and are vital for efficient battery management.

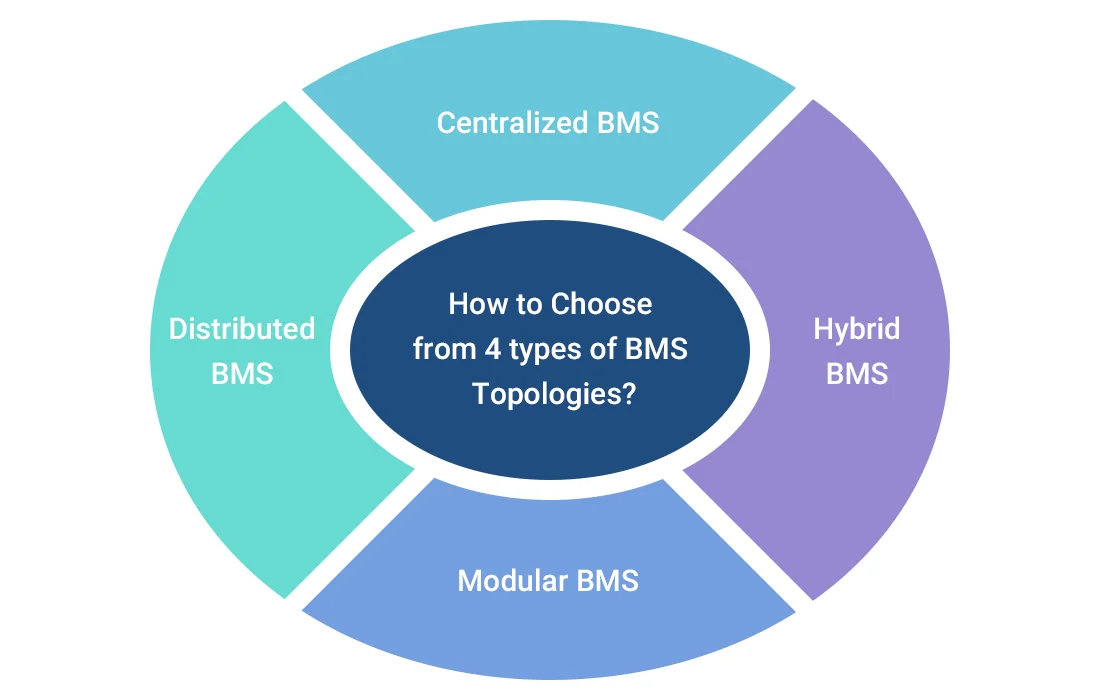

In this blog, we will explore four basic types of BMS topologies: centralized BMS topologies, distributed BMS topologies, modular BMS topologies, and hybrid BMS topologies. We will delve into the workings of each topology, discussing their battery architectures, key components, and how they contribute to battery performance optimization and safety. Additionally, we will compare the 4 types of Battery Management System topologies based on factors like scalability, flexibility, fault tolerance, and cost to provide valuable insights for making informed decisions.

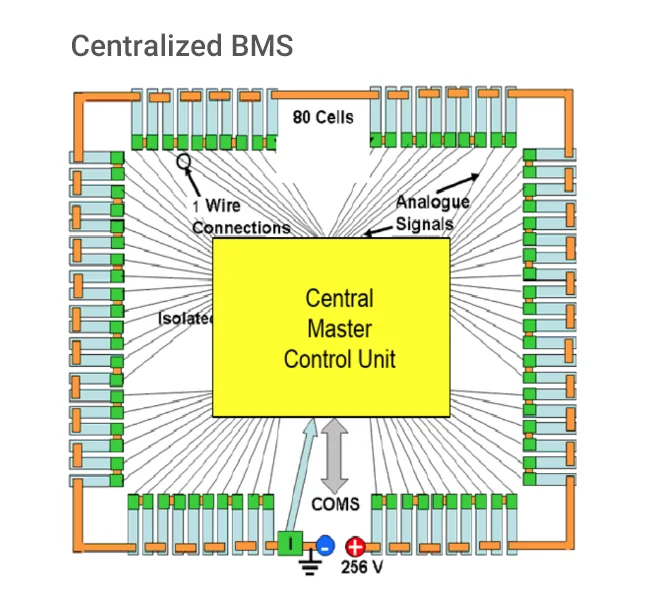

Centralized BMS Topologies

Centralized BMS topology is a configuration in which all battery monitoring and control functions are concentrated within a single central unit. This central unit acts as the brain of the system and is responsible for gathering data from individual battery cells or modules, processing the information, and making decisions based on predefined algorithms. The centralization of control simplifies the BMS design and communication within the system, as all information flows through a single point.

- Advantages and Limitations of the Centralized BMS Topology

Advantages:

- Precise Control: With direct access to data from all battery cells, a centralized BMS can provide accurate and real-time monitoring, leading to precise control and optimization of battery performance.

- Cost-Effectiveness: Centralized BMS systems are generally cost-effective, especially for smaller battery packs, as they require fewer components and communication links compared to distributed or modular systems.

- Simplified Integration: Due to its single-point control, integration with other vehicle or system components is usually straightforward, making it a preferred choice for automotive applications.

Limitations:

- Limited Scalability: The centralized approach may face challenges in handling larger and more complex battery systems, as the central unit may become overwhelmed with a high number of battery cells to monitor and control.

- Single Point of Failure: Since the entire BMS relies on the central unit, any malfunction or failure in this unit could potentially lead to a complete system shutdown.

- Increased Wiring Complexity: In larger systems, the centralized architecture may require extensive wiring to connect all battery cells to the central controller, leading to increased complexity and potential signal interference.

- Architecture and Components Involved in a Centralized BMS System

The architecture of a centralized BMS system consists of the following key components:

- Central Processor: The central processor, also known as the main controller, is the heart of the BMS. It collects data from various battery cells or modules and analyzes this information to determine the status of the battery pack.

- Cell Monitoring Circuits: Each battery cell or module is equipped with a monitoring BMS circuit that measures parameters such as voltage, current, and temperature. These circuits transmit data to the central processor.

- Communication Interfaces: Communication interfaces, such as CAN (Controller Area Network) or LIN (Local Interconnect Network), facilitate data exchange between the central processor and the individual cell monitoring circuits.

- Balancing Circuits: In cases where individual battery cells exhibit different charge levels, the central processor can command balancing circuits to equalize the charge across the cells by redistributing energy.

- Safety Features: The centralized BMS includes safety features like overcurrent protection, overvoltage protection, and overtemperature protection to safeguard the battery cells from potential hazards.

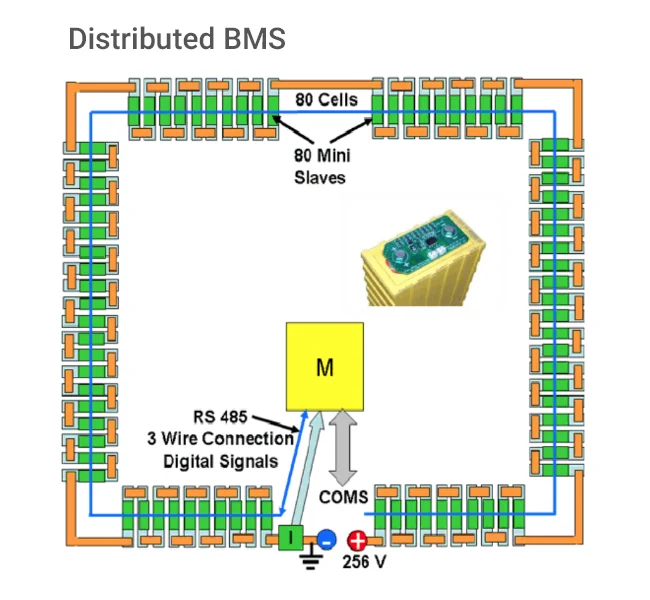

Distributed BMS Topologies

Distributed BMS topology, in contrast to the centralized approach, distributes intelligence across multiple nodes or sub-modules. Each node is responsible for monitoring and managing a subset of battery cells or modules independently. The nodes communicate with each other to coordinate their actions and collectively manage the entire battery pack.

- Advantages and Limitations of the Distributed BMS Topology

Advantages:

- Improved Reliability: The distribution of intelligence ensures that even if a node fails, the rest of the system can continue functioning, enhancing overall reliability.

- Enhanced Scalability: Distributed BMS can accommodate larger battery systems without overwhelming a central processor, making it ideal for applications requiring significant expansion capabilities.

- Simplified Wiring: In larger systems, distributed wireless battery management system topology may require less wiring than a centralized architecture, reducing complexity and signal interference.

Limitations:

- Increased Complexity: Distributed BMS may require more advanced communication protocols and coordination between nodes, leading to increased system complexity.

- Higher Implementation Costs: The redundancy and additional communication components can increase the initial implementation costs compared to a centralized BMS.

- Architecture and Components Involved in a Distributed BMS System

The architecture of a distributed BMS system comprises the following key components:

- Node Controllers: Each battery cell or module is associated with its dedicated node controller. These node controllers are responsible for monitoring the individual cells and reporting their status to neighboring nodes.

- Communication Network: The distributed approach relies on a communication network, such as CAN or Ethernet, which connects the node controllers. Nodes exchange information and collectively manage the battery system.

- Coordination and Decision Making: The node controllers communicate with each other to coordinate actions and make collective decisions for balancing and protection, ensuring that the entire battery pack operates optimally.

- Balancing Circuits and Safety Features: Each node may include balancing circuits and safety features to maintain cell balance and protect the battery cells from potential hazards.

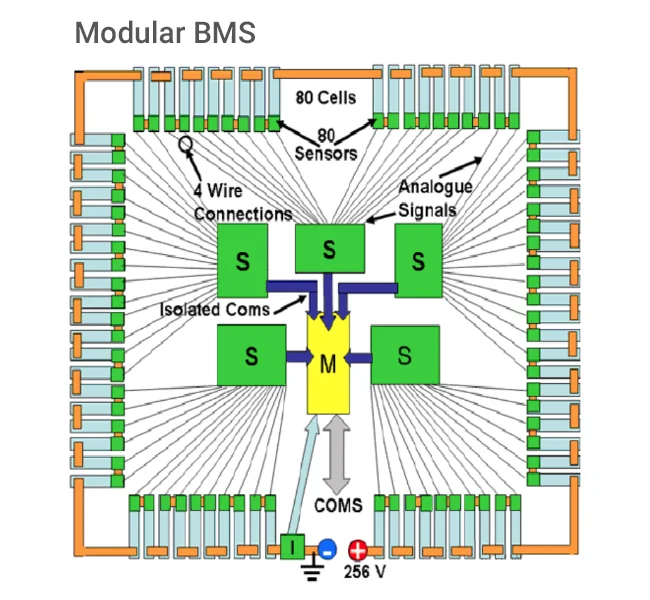

Modular BMS Topologies

Modular BMS topology divides the battery pack into smaller, self-contained modules, each equipped with its BMS. These modules are usually independent and can function autonomously, providing a high level of flexibility and scalability to the overall battery system.

- Advantages and Limitations of the Modular BMS Topology

Advantages:

- Flexibility: Modular BMS allows for a flexible design, making it suitable for various battery configurations and accommodating different application requirements.

- Easy Integration: Each module operates independently, simplifying integration with other vehicle or system components, such as power inverters or chargers.

- Reduced Downtime: In the event of a BMS failure, only the affected module needs to be repaired or replaced, minimizing downtime and ensuring continuous operation.

Limitations:

- Communication Complexity: The interconnection between modules requires a well-defined communication protocol to ensure proper coordination and control.

- Balancing Challenges: Ensuring proper balancing across modules can be more challenging than within a single centralized or distributed unit.

- Architecture and Components Involved in a Modular BMS System

The architecture of a modular BMS system consists of the following key components:

- Battery Modules: The battery pack is divided into individual modules, each containing a group of battery cells. These modules can be connected in series or parallel configurations based on system requirements.

- Module Controllers: Each battery module is equipped with its BMS controller, responsible for monitoring and managing the cells within that specific module.

- Inter-Module Communication: Modules communicate with each other and a central coordinator to exchange data and coordinate actions, such as balancing and protection, to ensure the entire battery pack operates efficiently.

- Central Coordinator: In some cases, a central coordinator may be included to manage communication between modules and oversee the overall battery system performance.

Hybrid BMS Topologies

Hybrid BMS topology combines elements of centralized, distributed, and modular approaches to achieve the most suitable configuration for specific applications. The hybrid approach aims to leverage the strengths of each topology while minimizing its limitations.

- Advantages and Limitations of the Hybrid BMS Topology

Advantages:

- Tailored Solutions: Hybrid BMS provides tailored solutions, offering the best combination of topologies to optimize battery management in diverse applications.

- Versatility: The hybrid approach can adapt to various battery sizes, complexities, and performance requirements, making it suitable for a wide range of industries.

Limitations:

- Design Complexity: Integrating multiple battery management systems topologies can increase design complexity, requiring careful planning and coordination.

- Potential Cost Increase: Depending on the combination of topologies used, a hybrid BMS may involve higher implementation costs compared to singular approaches.

- Architecture and Components Involved in a Hybrid BMS System

The architecture of a hybrid BMS system will vary based on the specific combination of centralized, distributed, or modular elements tailored to the application’s requirements.

In a hybrid system, certain battery modules may operate under a distributed BMS, while others use a centralized or modular BMS. The various components and communication interfaces will be designed to facilitate seamless integration and coordination between different BMS approaches.

Centralized vs Distributed vs Modular vs Hybrid: 4 BMS Topologies Comparison

Comparison Table

Below is a comparison table highlighting the key differences between centralized, distributed, modular, and hybrid BMS topologies based on scalability, flexibility, fault tolerance, cost, and other important factors:

| ASPECT | CENTRALIZED | DISTRIBUTED | MODULAR | HYBRID |

|---|---|---|---|---|

| Scalability | Limited | High | High | High |

| Flexibility | Limited | High | High | High |

| Fault Tolerance | Low | High | Moderate | High |

| Redundancy | Minimal | High | Moderate | High |

| Communication Complexity | Low | High | Moderate | Moderate |

| Integration Simplicity | High | Moderate | High | Moderate |

| Cost | Low | Moderate | Moderate | Varies |

Suitability of Each Topology for Different Applications and Battery Systems

- Centralized BMS Topologies

Suitability: Centralized BMS is suitable for smaller battery systems with relatively simple architectures. It is commonly used in applications where cost and simplicity are essential factors, such as small electric vehicles, portable devices, and low-power energy storage systems.

Considerations: For larger and more complex battery systems, the limited scalability and fault tolerance of a centralized BMS may become a concern, as it may struggle to handle the increasing number of cells and communication links.

- Distributed BMS Topologies

Suitability: Distributed BMS is ideal for larger battery systems with high scalability requirements, such as electric buses, grid energy storage, and industrial energy storage solutions. It offers excellent fault tolerance and redundancy, making it suitable for critical applications where system downtime must be minimized.

Considerations: The complexity of communication between nodes may increase implementation costs, and careful coordination is essential to ensure seamless cooperation between distributed nodes.

- Modular BMS Topologies

Suitability: Modular BMS is well-suited for applications that require flexibility and scalability. It is commonly used in electric vehicles, data centers, and large-scale energy storage systems where modules can be added or removed as needed, allowing for easy expansion and maintenance.

Considerations: While offering high flexibility, the communication complexity between modules and the challenge of balancing across modules should be carefully addressed during the design phase.

- Hybrid BMS Topologies

Suitability: Hybrid BMS provides the most customizable solution, making it suitable for applications with specific requirements that can benefit from a tailored combination of topologies. It is often used in advanced electric vehicles, high-performance energy storage, and critical industrial applications.

Considerations: Designing a hybrid BMS requires a thorough understanding of the system’s needs, and the implementation costs may vary depending on the combination of topologies chosen.

In summary, the choice of BMS topology should align with the specific requirements of the battery system and application. Centralized BMS is cost-effective and straightforward, best suited for smaller and less complex systems. Distributed BMS offers high scalability and fault tolerance, making it ideal for larger and more critical applications. Modular BMS provides flexibility and scalability, making it suitable for various industries. Hybrid BMS allows for customization, offering a tailored solution for specific needs. Understanding the trade-offs and advantages of each topology will help in making informed decisions to optimize battery performance and safety.

Centralized vs Distributed vs Modular vs Hybrid: Which Topology Best Meets Your Needs?

Selecting the most suitable Battery Management System (BMS) topology is a critical decision that depends on various factors. When evaluating BMS topologies, consider the following key factors:

Battery System Size and Complexity

The size and complexity of the battery system play a significant role in determining the suitable BMS topology. Smaller and less complex systems may be well-served by a centralized BMS, while larger and more complex systems may require distributed or modular BMS for scalability and fault tolerance.

Application Requirements

Different applications have varying demands on battery systems. For example, electric vehicles require high reliability, fault tolerance, and real-time monitoring, making distributed or hybrid BMS more suitable. Renewable energy storage systems may benefit from modular BMS for flexibility and ease of expansion.

Scalability and Expandability Needs

Consider the future growth and expansion requirements of the battery system. If there is a possibility of adding more battery cells or modules in the future, a scalable BMS topology like distributed or modular may be preferred.

Fault Tolerance and Redundancy

Critical applications, such as medical devices or grid-scale energy storage, may demand high fault tolerance and redundancy. In such cases, distributed or hybrid BMS can provide redundancy and maintain system operability even in the event of component failures.

Cost Considerations

Evaluate the budget constraints for the project. Centralized BMS may be more cost-effective for smaller battery systems, while distributed or modular BMS can involve higher initial costs but offer better long-term scalability.

Each topology brings its own set of advantages and limitations, and understanding these factors will help make an informed decision to ensure optimized battery performance, safety, and reliability for a given application.

BMS Topologies Real-World Examples

- Electric Vehicles (EVs)

Tesla Model S: Tesla’s electric vehicles use a centralized BMS topology. The central controller gathers data from thousands of individual battery cells to optimize charging and discharging, improve range, and ensure the safety of the battery pack.

Nissan Leaf: The Nissan Leaf, an electric car, utilizes a distributed BMS topology. Each battery module has its controller, and the nodes communicate to manage the entire battery pack efficiently.

BMW i3: The BMW i3 employs a modular BMS topology. The battery pack is composed of individual modules, each with its BMS, allowing for easy expandability and maintenance.

- Grid Energy Storage

MOKOEnergy: MOKOEnergy is a BMS board manufacturer, we specialize in BMS PCB, smart energy management devices, and other energy storage and management solutions. Our BMS for grid energy storage includes several BMS topologies, such as centralized, distributed, modular, and hybrid. The products in the new energy series are capable of storing and dispatching electricity using BMS for lithium ion batteries, making them suitable for large-scale grid energy storage systems. This plays a significant role in enhancing grid stability and supporting the transition to renewable energy.

- Portable Devices

Smartphones and Laptops: Portable devices like smartphones and laptops typically use a centralized BMS topology. The BMS monitors the individual battery cells to optimize charging and prolong battery life.

Power Banks: Some power banks use a modular BMS topology, where battery cells are grouped into modules with individual controllers, allowing for expandability and customization.

Conclusion

As battery technology continues to evolve, choosing the appropriate BMS topology has become crucial for maximizing the potential of battery systems. Centralized BMS offers simplicity and low cost but may lack scalability. Distributed BMS provides high scalability and fault tolerance but adds communication complexity. Modular BMS allows for flexibility and easy maintenance but may face balancing challenges. Hybrid BMS offers customization by combining topologies. Choosing the appropriate topology based on battery system size, complexity, and application needs optimizes performance, safety, and cost-effectiveness, contributing to a greener and more sustainable future.

MOKOEnergy is a company that specializes in providing solutions for new energy devices, especially BMS boards. With up to 17 years of research and development experience, our new energy management products and services are widely used in key power supply areas such as new energy developers, residential, grid, transportation, commercial, and industrial sectors. For further inquiries about battery management systems, please feel free to contact us. By communicating with our professional team of experts, we can provide you with suitable BMS solutions.

CONTINUE READING ABOUT THE BATTERY MANAGEMENT SYSTEM TOPOLOGIES