In today’s digital age, we are currently witnessing a proliferation of new battery-enabled applications on the market as battery technology continues to evolve. However, the widespread use of batteries has also brought about current problems, where the presence of overcurrents can lead to catastrophic accidents such as equipment failures, fires, and even explosions. Therefore, overcurrent protection has become a key element in ensuring the safety of battery applications. This paper will introduce the concept of overcurrent protection, discuss the risks of not BMS overcurrent protection, and highlight the battery management system and battery protection board as two excellent overcurrent protection solutions.

Understanding BMS Overcurrent Protection

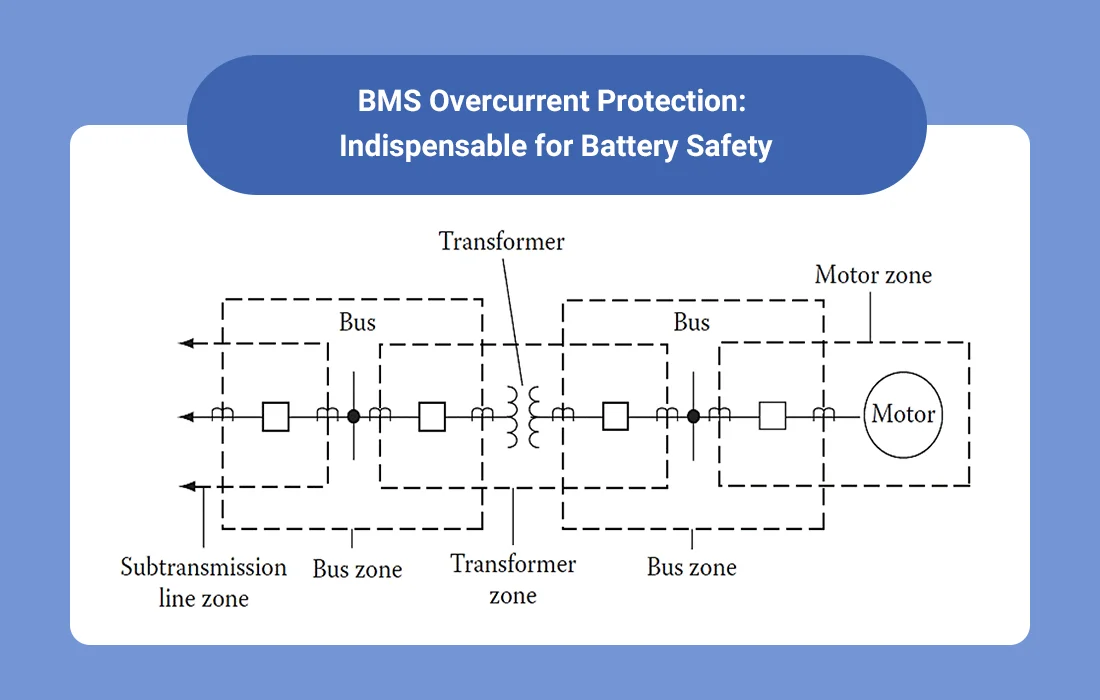

BMS overcurrent protection involves a protective device taking action when the current surpasses a predefined maximum limit. When the current in the protected circuit exceeds the preset threshold, the protective device intervenes actively, employing timing mechanisms to ensure the selectiveness of its response. This can result in either the circuit breaker tripping or the transmission of an alarm signal.

Many electronic devices come with a specified current rating. When these devices surpass their rated current, it results in equipment damage. Consequently, manufacturers incorporate a current protection module into these devices. When the current exceeds the predefined threshold, the device automatically activates the protective mechanism, which is known as overcurrent protection. The USB interface, such as computer motherboard USB over-current protection is generally going to protect the motherboard was burning down.

Overcurrent protection includes short circuit protection and overload protection:

- Short circuit protection is distinguished by its substantial set current and immediate response. Electromagnetic current tripper (or relay) and fuse are commonly used as short circuit protection components.

- The overload protection stands out for its low setting current and its action that counters time limits. Thermal relays and delay-type electromagnetic current relays are commonly used as overload protection components. Fuse is commonly used as an overload protection device, inrush current.

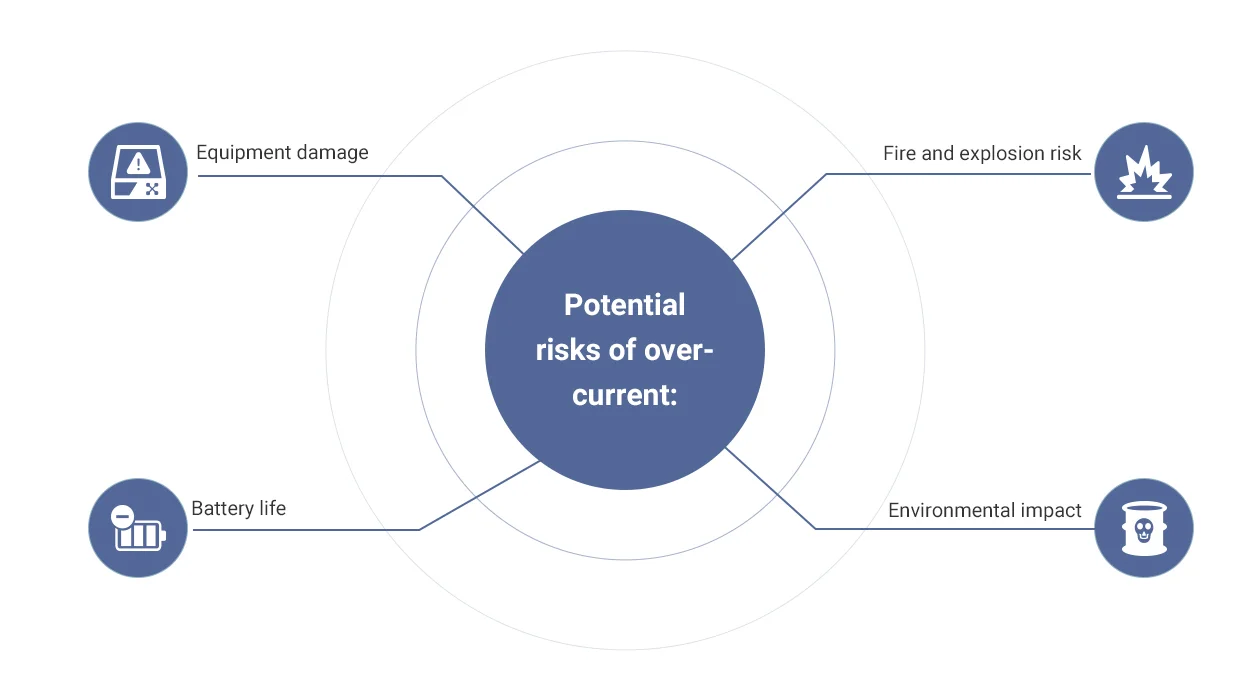

Potential Risks of Overcurrent

Overcurrent protection becomes crucial when it comes to battery safety, as overcurrent problems can trigger a series of adverse effects:

Equipment damage

Overcurrent may be one of the main causes of electronic equipment damage. Electronic components such as capacitors, resistors, transistors, etc., all have specific current ratings, and exceeding these ratings may cause these components to overheat, burn out, or become damaged. This has the potential to diminish the facility’s performance or even render it entirely nonfunctional.

Fire and explosion risk

In some cases, excessive current may cause the battery to overheat and cause a fire or explosion. This is especially dangerous for applications such as electric vehicles and energy storage systems, which use high-capacity and high-power battery packs. Overcurrent protection can detect and prevent this situation in time to ensure the safety of users and the environment.

Battery life

The life of the battery is related to the current it receives. Excessive current can trigger chemical reactions inside the battery, leading to battery polarization or electrolyte loss, which will accelerate the aging process of the battery and shorten the battery life. Through over-current protection, the aging rate of the battery can be reduced, the service life of the battery can be extended, and the cost can be reduced.

Environmental impact

Frequent replacement or discarding of damaged electronic devices generates a large amount of electronic waste, which has a negative impact on the environment. Overcurrent protection helps reduce the generation of this waste and reduces the environmental pollution of e-waste.

BMS and Battery Board: Overcurrent Protection Solution

BMS

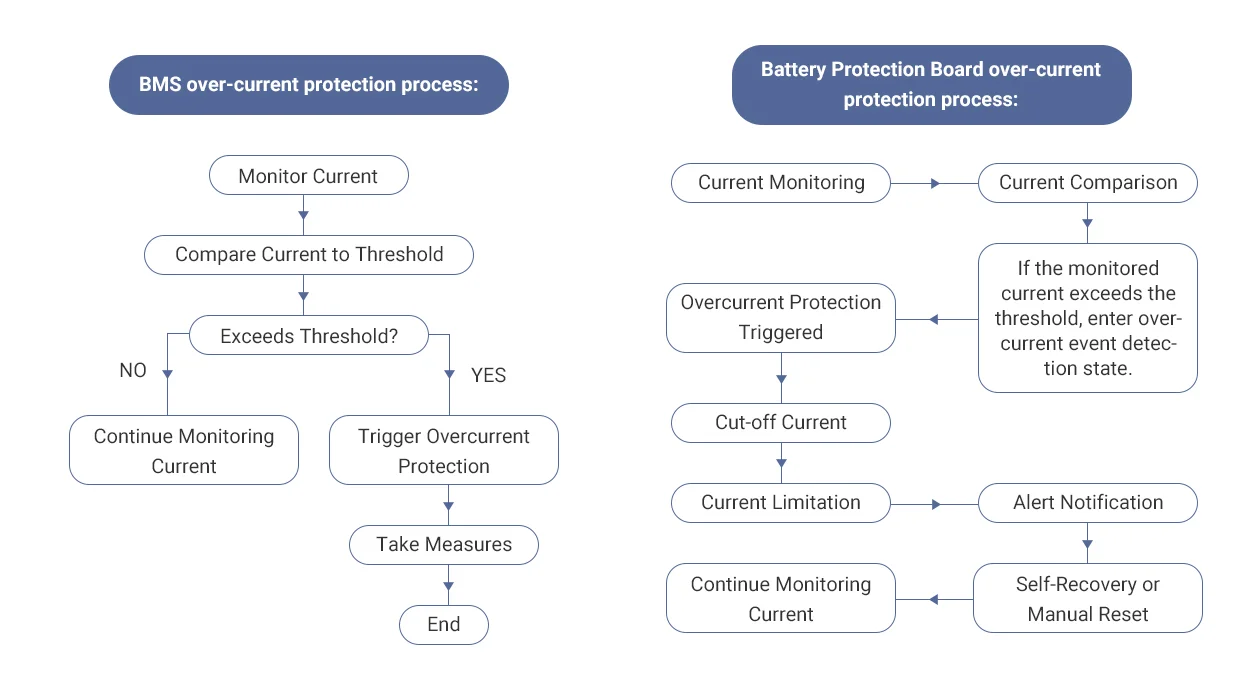

The battery management system, or BMS for short, is one of the key components in a battery pack that monitors, controls, and protects the battery, including BMS overvoltage protection and overcurrent protection. The following is the working principle of BMS for overcurrent protection:

1. Current monitoring: The BMS employs current sensors for actively monitoring the real-time current within the battery pack. These sensors are typically constructed based on the principle of current Hall effect or resistance. By monitoring the current, the BMS is able to track the charging and discharging process of the battery pack as well as any abnormalities.

2. Current comparison: The BMS compares the monitored current with pre-set safety thresholds. These thresholds are set according to the specifications and design requirements of the battery. If the monitored current exceeds the threshold, the BMS will recognize the situation as an overcurrent event.

3. Overcurrent protection trigger: Once the BMS detects an overcurrent event, it will trigger the BMS overcurrent protection mechanism. This mechanism can take a variety of measures to reduce the current to protect the battery and related equipment from damage or hazardous conditions caused by overcurrent.

a. Current disconnect: One of the most common responses to an overcurrent is to disconnect the battery charging or discharging circuits. The BMS can quickly stop the flow of current by disconnecting the associated relay or transistor. b. Current Limit: Sometimes the BMS will detect an overcurrent event and trigger a BMS overcurrent protection mechanism.

b. Current limiting: Sometimes the BMS will limit the flow of current so that it is within safe limits. You can achieve this by actively modifying the charging or discharging current of the battery to guarantee it stays below a predetermined threshold.

c. Alarm notification: The BMS can also trigger an alarm system to notify the operator or user that an overcurrent event has occurred. This helps to take timely action such as stopping charging or discharging and checking the status of the battery pack.

4. Data logging and reporting: The BMS typically records the occurrence of an overcurrent event, including time, current value, and other relevant information. This data is important for troubleshooting, maintenance, and improving battery system performance.

In summary, the BMS overcurrent protection working principle of a BMS involves monitoring the current within the battery pack in real time, comparing it to a preset safety threshold, and taking appropriate measures to protect the safety of the battery and equipment when an overcurrent event is detected. This BMS overcurrent protection mechanism is a critical part of the battery system and ensures battery stability, longevity, and user safety.

Battery Protection Board

The battery protection board is a protective device used in battery packs, and one of its main functions is to provide overcurrent protection. Here is how the battery protection board works for overcurrent protection:

1. Current monitoring: The battery protection board is connected to the positive and negative terminals of the battery pack and monitors the flow of current in real-time by means of a current sensor or current measurement circuit. This is usually done by detecting a BMS over voltage drop in the circuit or by using a current sensor.

2. Current comparison: The battery protection board has a built-in microcontroller or specialized integrated circuit that compares the monitored current with preset current thresholds. These thresholds are pre-set according to the battery specifications and design requirements.

3. Overcurrent protection trigger: When the battery protection board detects that the current has exceeded the set safety threshold, it will trigger the overcurrent protection mechanism to avoid damage to the battery and equipment caused by excessive current.

a. Cutting off current: The most common overcurrent protection measure is to cut off the current flow to the battery. Battery protection boards are usually equipped with a set of relays or MOSFETs. When the overcurrent protection is triggered, these switching elements will quickly disconnect the current path, preventing further current flow.

b. Current limiting: Some battery savers utilize a current limiting method where they dynamically adjust the current to limit it to a safe range rather than cutting it off completely.

c. Alarm notification: Some battery protection boards can also trigger an alarm to notify the user or operator that an overcurrent event exists so that they can take appropriate action to resolve the problem.

4. Self-recovering or manual reset: In some cases, battery protection boards have a self-recovering feature that will automatically reset once the current drops to a safe level. In other cases, users may need to manually reset the battery saver to continue using the battery pack.

In summary, the overcurrent protection working principle of the battery protection board includes real-time monitoring of the current, comparing it with a set threshold, and triggering overcurrent protection measures (such as cutting off the current, limiting the current, or sending out an alarm notification) to protect the safety of the battery and the device. This overcurrent protection mechanism is critical to the stable operation of the battery pack and prolonging battery life.

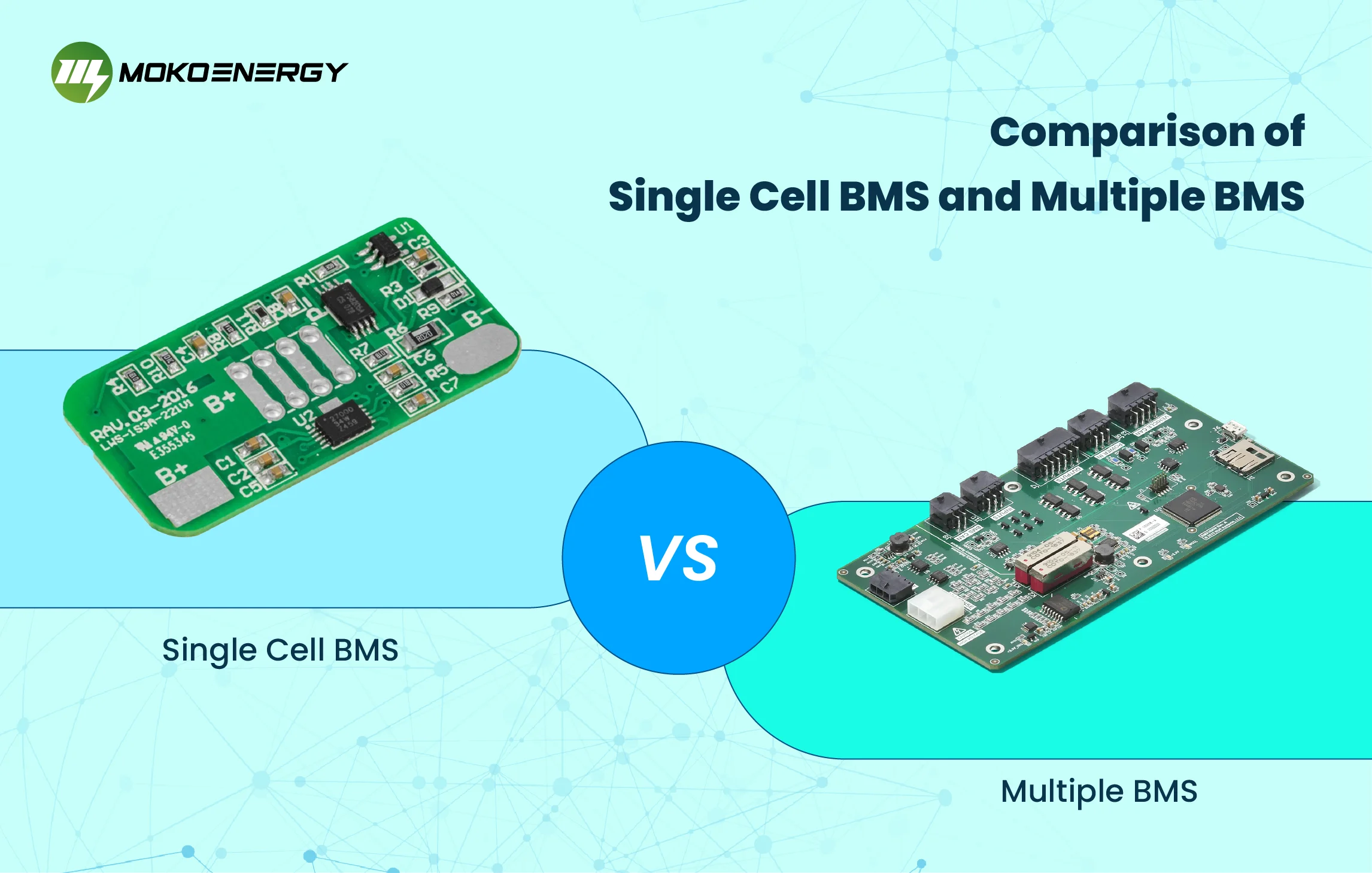

Comparison of BMS and Battery Board in Terms of Overcurrent Protection

From the above, it can be seen that both BMS and battery protection boards can effectively carry out overcurrent protection and ensure the safety of the use of facilities, so what is the difference between them? Let’s examine the distinctions in a table to help you make a more informed choice between the two.

| FEATURE | BMS | BATTERY PROTECTION BOARD |

|---|---|---|

| Position and Scope | Typically the central control system of the battery pack | Usually located within the battery pack |

| Complexity | Complex, dealing with multiple battery cells or modules | Relatively simple, focusing on a single battery pack |

| Monitoring Precision | High, capable of detecting and responding to small current variations | Lower, suitable for small-scale battery packs |

| Application Range | Used in large battery packs such as electric vehicles and energy storage systems | Used in small battery packs like portable power banks and power tools |

| Overcurrent Protection Mechanism | Offers multiple options, including dynamic current adjustment, cutting off the current, issuing alerts, etc. | Typically responds to overcurrent events by cutting off the current |

MOKOEnergy‘s BMS and Battery Board Solution is the Best in Over-current Protection

Overcurrent protection refers to the lithium battery in the power supply to the load, the current will change with the change of voltage and power, when the current is very high, it is easy to burn the protection board, battery, or equipment. The overcurrent protection function of either the protection board or the battery management system actively monitors the battery pack’s current in real time during the charging and discharging process. When the current surpasses the safe limits, it promptly interrupts the current flow, preventing potential damage to the battery or equipment, and effectively fulfilling its protective role.

MOKOEnergy has studied battery safety, especially overcurrent protection, and with the efforts of more than 70 R&D staff, we have introduced a battery management system and a battery protection board that effectively protects the battery pack:

Battery Management System

The BMS improves the overcurrent protection performance and safety of battery packs consisting of multiple cells. Functional safety is critical because commonly used lithium-ion batteries or other batteries can easily pose a major safety hazard when operated outside of safe operating areas. That’s why our BMS products support ASIL D functional safety capabilities under the additional ISO 26262, maintaining safe performance even when application scenarios are under extreme conditions, such as under severe temperature, humidity, and current variations.

Dedicated to BMS overcurrent protection for high-capacity and high-power automotive and industrial applications, we offer BMS solutions including complete chipsets, software, and functional safety documentation. Through our reference designs, we have established friendly relationships with customers in several countries and continue to provide the latest BMS innovations for applications such as sustainable mobility and renewable grids.

Battery Protection Board

When a customer overshoots the discharge current of a lithium battery protection board, the board will overheat and the wires inside the battery will overheat, which can cause thermal damage. This can seriously cause the battery to catch fire.

With the MOKOEnergy board’s lithium battery protection board overvoltage protection and current protection function, short circuits and current can be avoided, making the use of the battery safer. The same 50A or discharge current of the same protection board, different companies may use different programs, we use high-end cutting-edge battery protection boards that are usually equipped with micro-controllers and special integrated circuits, you can realize real-time monitoring of the current, and at the same time, its protection will be more accurate and rapid. If the protection board is not accurate, may cause the critical moment of protection to be too slow to lead to direct breakdown of the protection board.

Conclusion

BMS overcurrent protection is crucial in electronic facilities and battery management, it helps to prevent catastrophic accidents, prolongs the life of the equipment, and improves the safety of the battery. BMS and battery protection boards are excellent overcurrent protection tools, they provide solid safety for our electronic devices so that we can enjoy modern technology with more peace of mind. When choosing the right overcurrent protection solution for your application, consider MOKOEnergy products, which represent the best in reliability and performance. If you need any help, you can come to us.

CONTINUE READING ABOUT THE BMS OVERCURRENT PROTECTION