Nowadays, new energy is becoming more and more popular. As a management system, BMS (Battery Management System) is important for new energy, especially for electric vehicle batteries. As the complexity of a machine increases, it typically requires more energy to operate, leading to a higher demand for batteries. But how can we use the batteries more scientifically? How does BMS work and optimize the batteries? This article gives answers. We provide a guide on BMS, covering its origin, applications, and forecasting its bright future.

What is the BMS Battery Management System?

A battery management system (BMS) refers to an electronic system responsible for overseeing the operations of a rechargeable battery, whether it is an individual cell or a battery pack. The BMS performs various functions, including safeguarding the battery from operating beyond its safe range, monitoring its current state, generating additional data, reporting that data, controlling the battery’s environment, authenticating it, and ensuring its balance.

People mainly use BMS in large-scale battery systems and can apply it in automobiles and energy storage. The primary function of BMS is to control battery packs, performing tasks like safety protection, charging and discharging management, and information monitoring.

Why Do We Need a BMS Battery Management System?

The importance of BMS becomes obvious when it comes to electric vehicles. The BMS serves as a link between the battery and the vehicle. It deals with complex signals such as battery cell voltage, collision, CAN, charging, water pump, high voltage, insulation, and so on. Overcharging a battery once might result in irreversible damage. Severe instances can cause lithium-ion batteries to overheat or overcharge, resulting in thermal runaway, battery rupture, or even explosion.

To avoid overcharging, over-discharging, and overheating, BMS must rigorously control charging and discharging. The primary power source for electric cars is lithium-ion batteries. Maintaining quality during lithium-ion battery mass production can be difficult, and inconsistent performance can lower lifespan and efficiency. Safety problems like fire and explosion can occur as a consequence of excessive charging or discharging.

Using BMS, you may carefully assess the battery pack’s utilization state, safeguarding it from overcharging and over-discharging. BMS balances battery pack charging levels, calculates charging levels, and turns them into understandable scope information. This assures safe functioning and increases the battery’s longevity.

Evolution of BMS Battery Management System

The concept of BMS can be traced back to the beginning of battery technology in the 1970s. However, it was not until the development of electric vehicles, especially plug-in hybrid electric vehicles, that BMS truly entered people’s vision.

BMS has evolved from simple protection circuits to more powerful intelligent management systems. The main advancements and developments include:

- Standardization of peripheral interface protocols

- Development of reversible thermal management

- Improvement of charging balancing solutions

- Strengthening of safety protection measures

- Application of big data analysis

Overall, the progress and development of BMS in the field of batteries provide strong support for battery longevity, high performance, and high reliability.

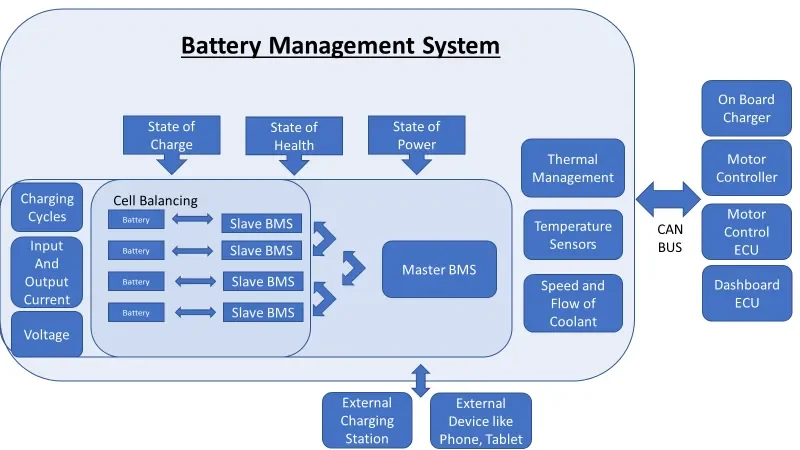

How Does BMS Battery Management System Work?

The Battery Management System (BMS) consists of a computer that is connected to multiple sensors. These sensors are responsible for observing and measuring the voltage, current, and temperature of every cell, and they transmit this data to the BMS.

After receiving the data, the Battery Management System evaluates the information to guarantee that every cell functions within the specified boundaries. If any cell exceeds these limits, the BMS makes efforts to resolve the issue and rectify the problem.

In the event that the cells within the battery pack reach elevated temperatures, the BMS takes charge of regulating the cooling system to lower the overall temperature of the battery pack.

In case of variations in cell voltage, the Battery Management System performs cell balancing. In order to equalize the voltage levels across all cells, the Battery Management System (BMS) facilitates the transfer of energy from one cell to another. This process aims to maintain a consistent voltage level among all the cells.

Components of BMS Battery Management Systems

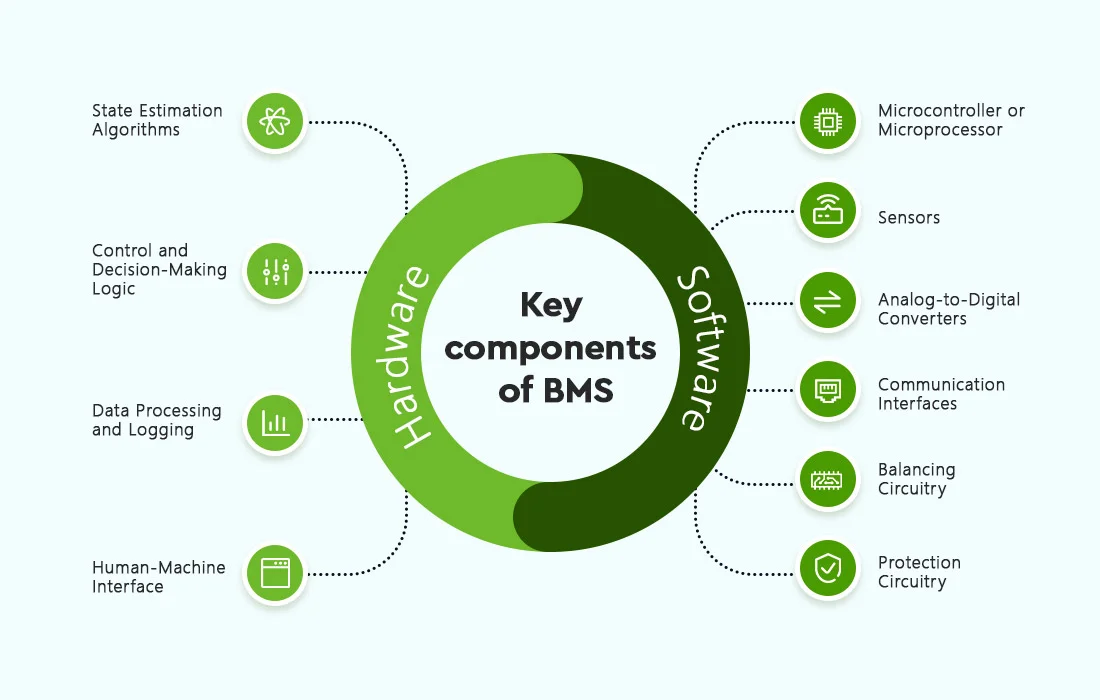

Hardware

Microcontroller or Microprocessor: The heart of the BMS is a microcontroller or microprocessor unit (MCU/MPU) that performs various functions and executes the BMS software. It processes data, controls peripheral devices, and communicates with external systems.

Sensors: BMS incorporates various sensors to measure parameters such as battery voltage, current, temperature, and sometimes humidity. These sensors provide crucial input for monitoring battery performance and ensuring safe operation.

Analog-to-Digital Converters (ADC): ADCs transform analog signals obtained from sensors, such as voltage and current sensors, into digital signals that can be effectively handled by the microcontroller. They enable accurate measurement and monitoring of battery parameters.

Communication Interfaces: BMS may include communication interfaces to exchange data with external devices or systems. Common communication protocols used in BMS include CAN , RS-485, Ethernet, SPI, and I2C.

Balancing Circuitry: In systems with multiple cells or modules, balancing circuitry is used to equalize the charge among individual cells. It typically consists of balancing resistors, switches, and control circuitry to redistribute energy and maintain uniform voltage levels.

Protection Circuitry: BMS incorporates protection circuitry to safeguard the battery against overvoltage, undervoltage, overcurrent, and overtemperature conditions. This circuitry may include voltage supervisors, current limiters, temperature sensors, and relays to disconnect or isolate the battery when necessary.

Software

The core of the entire system is the software of the BMS as it governs all hardware operations and performs analysis on sensor data to make decisions and estimate the system’s state. Functions such as switch control, monitoring the sample rate of sensors, controlling cell balancing, and even designing dynamic safety circuits are all managed by the BMS software.

State Estimation Algorithms: The software embedded in the BMS contains algorithms that utilize measured voltage, current, temperature, and other factors to estimate the SoC and SoH of the battery. These algorithms employ mathematical models and calibration data to provide accurate estimates.

Control and Decision-Making Logic: BMS software includes control algorithms that determine the actions and commands for various BMS functions, such as cell balancing, protection activation, charging/discharging control, and fault handling. These algorithms ensure safe and efficient battery operation.

Data Processing and Logging: BMS software processes the data from sensors and converts it into meaningful information. It performs calculations, data filtering, and signal processing to monitor battery performance, track SoC/SoH, and detect anomalies. BMS software may also log data for analysis, diagnostics, and future optimization.

Human-Machine Interface (HMI): Some BMS implementations include software components for user interaction and visualization. These may include graphical user interfaces (GUIs), display panels, touchscreens, or remote monitoring interfaces for users to access battery status, diagnostics, and configuration options.

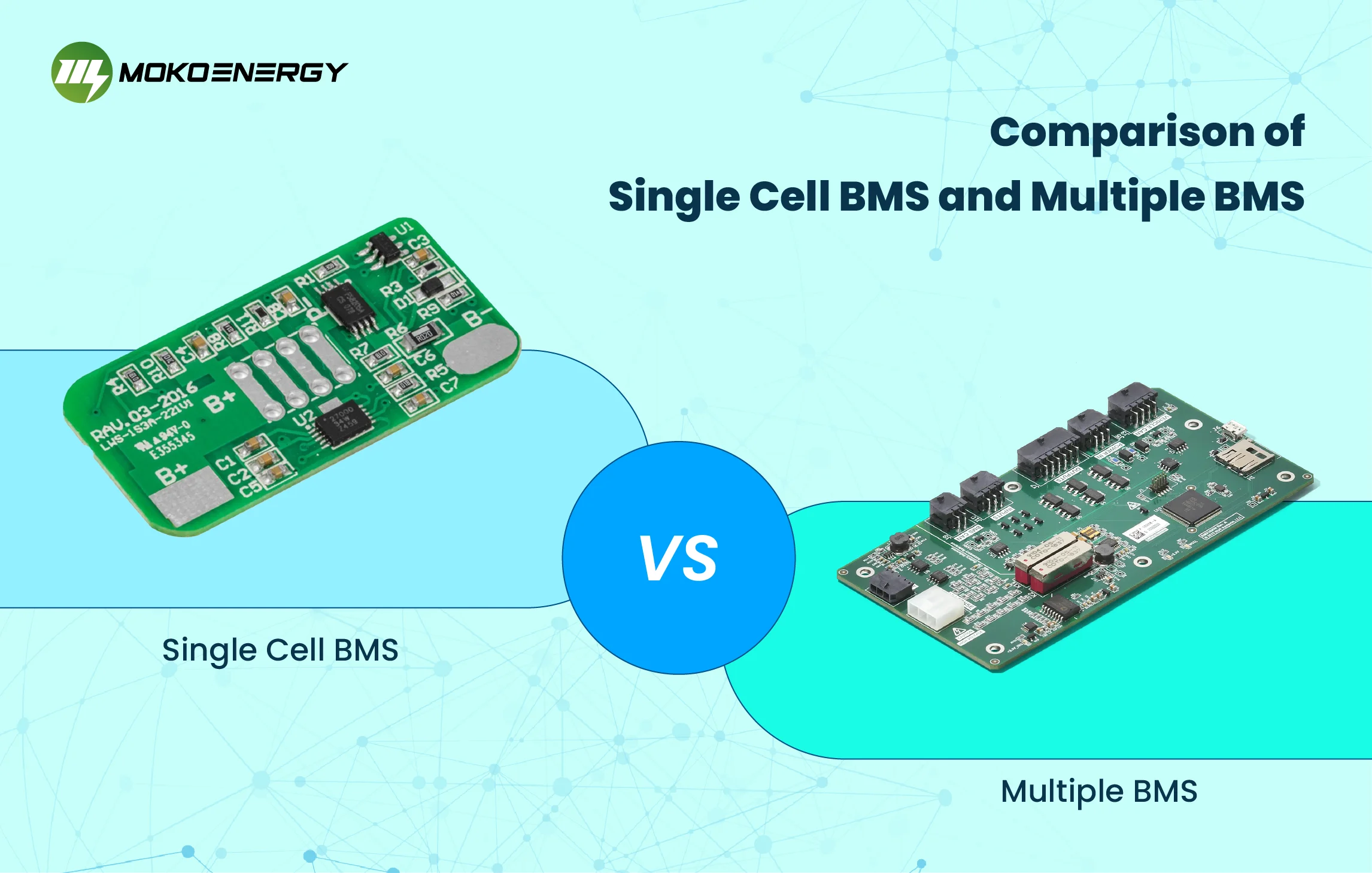

Types of BMS Battery Management Systems

Based on different Control methods: Passive BMS, Active BMS, and Hybrid BMS

If we classify BMS according to their control method, they can be divided into Passive BMS, Active BMS, and Hybrid BMS.

- Passive BMS: Passive BMS relies on passive balancing techniques to equalize the charge among battery cells. It does not actively control the charge transfer.

- Active BMS: Active BMS actively controls the charge transfer among battery cells using active balancing techniques. It can redistribute energy between cells to maintain balanced voltages.

- Hybrid BMS: The Hybrid BMS integrates passive and active balancing methods to achieve optimal battery performance and balance.

Based on different system architectures: Centralized BMS, Distributed BMS, and Modular BMS

If we classify BMS according to their system architecture, they can be divided into Centralized BMS, Distributed BMS, and Modular BMS.

- Centralized BMS: In a centralized BMS, a single central control unit manages and monitors all battery cells or modules in the system. It consolidates data and makes decisions based on the overall system status.

- Distributed BMS: Distributed BMS distributes control and monitoring functions among multiple battery management system modules or units, each responsible for a subset of battery cells or modules. These modules communicate with each other to exchange information and coordinate actions.

- Modular BMS: Modular BMS consists of independent BMS modules, each managing a separate battery pack or section. These modules can operate autonomously while sharing information with each other when needed.

Based on different communications: Wired BMS and Wireless BMS

BMS can also be classified into two categories by their communications. They are Wired BMS and Wireless BMS.

- Wired BMS: Wired BMS uses physical wired connections, such as CAN (Controller Area Network), RS-485, or Ethernet, to transmit data between the BMS components and the external systems.

- Wireless BMS: Wireless BMS utilizes wireless communication technologies, such as Bluetooth, Wi-Fi, or Zigbee, to transmit data between the BMS components and external devices. Wireless BMS offers flexibility in installation and reduces the need for physical wiring.

A Comparison Table of BMS Types

| BMS TYPE | DESCRIPTION | ADVANTAGES | DISADVANTAGES | APPLICATIONS |

| Passive BMS | A basic BMS that monitors cell voltages | Often used in applications that require wireless data transmissions, such as electric vehicles, and portable electronics | Limited functionality and frequent balancing required | Power tools, e-bikes, uninterruptible power supply (UPS) |

| Active BMS | Electronic switches for balancing cells | More efficient and advanced than Passive BMS | Expensive and complex to implement | Electric vehicles, aerospace, high-end energy storage |

| Hybrid BMS | Combination of Passive and Active BMS | Balances functionality and cost | Limited functionality compared to more specialized BMS | Mid-range electric vehicles, industrial energy storage |

| Centralized BMS | Monitors and controls batteries in one central location | Easy maintenance and detection of battery problems | Wiring complexity, risk of single-point failure (SPOF) | Large-scale energy storage systems, electric vehicles, management of a large number of cells |

| Distributed BMS | Various nodes monitor individual cells on the battery | Prolongs battery lifespan by reducing stress on cells | Complex communication and management | Small-scale energy storage systems, portable electronics, battery packs with a relatively small number of cells |

| Modular BMS | A scalable BMS designed to provide flexibility in size | Ability to adapt to various battery sizes and configurations | Additional assembly complexity and cost | Energy storage systems, electric vehicles, scalable applications |

| Wired BMS | Uses wired communication methods | High data integrity, reliable communication, and a relatively low risk of interference | Limited flexibility, susceptibility to physical damage to wires, installation can be challenging, and cost can be high | Generally used in applications that prioritize data reliability and security such as energy storage systems and medical devices |

| Wireless BMS | Uses radio-frequency (RF) communication | Convenient and practical, can be used in applications where physical wiring is impossible or impractical, and a low risk of physical damage to the wires | Susceptibility to interference, reduced data integrity, the possibility of security breaches, and the need for careful maintenance | Small-scale energy storage systems, portable electronics, battery packs with a relatively small number of cells |

What Can We Benefit from the BMS Battery Management System?

Improved Performance by Monitoring

By using balancing management, it can ensure that the voltage difference between cells in the battery pack is not significant, thereby improving the overall charging and discharging performance of the battery pack.

Battery Health Management (BHM) technology can perform real-time monitoring and diagnostics of the battery’s health status, allowing users to understand the battery’s condition at any time and facilitate timely monitoring and maintenance. In addition, the data acquisition function of the BMS protection board can also predict battery faults or abnormal conditions in advance, and take corresponding maintenance and repair measures.

Enhanced Battery Safety and Reliability

The BMS (Battery Management System) protection board plays an important role in preventing problems such as overcharging, over-discharging, and short circuits. It can effectively reduce the risk of battery damage or even fire, thus protecting personal and property safety.

Prolonged Battery Lifespan

The BMS real-time collects, processes, and stores important information during the battery pack operation, exchanges information with external devices such as the vehicle control unit, and solves key issues such as safety, availability, usability, and service life in the lithium battery management system. Its main function is to improve the utilization of the battery, prevent overcharging and over-discharging of the battery, extend the battery’s service life, and monitor the battery’s status.

BMS Battery Management System Technologies

Lithium Battery Monitoring System

The Lithium Battery Monitoring System is a complex monitoring and control system based on lithium-ion batteries. In addition to basic battery management functions, it is also capable of providing battery forecasting and safety assurance and can monitor and report the real-time status of the battery.

Bluetooth and wireless BMS Solutions

Bluetooth and wireless BMS solutions utilize wireless technologies such as Bluetooth, WiFi, etc. to connect the battery management system with other devices such as smartphones, tablets, etc. This enables remote control and data transfer.

BMS Integration with the IoT

Connecting the battery management system to the IoT platform enables data exchange, and information-sharing, and improves battery system reliability and efficiency.

Advanced BMS Algorithms and Analytics

Advanced BMS algorithms and analysis techniques use big data and AI to analyze and predict battery state and performance. Based on the analysis results, they optimize and control energy storage systems. This can enhance the durability and longevity of batteries.

Applications of BMS Battery Management System

Here are the applications of BMS:

Electric vehicles (EVs) and hybrid vehicles: BMSs in EVs and hybrid vehicles are responsible for managing the battery pack, ensuring optimal performance, and preventing overcharging or deep discharge. They also monitor the temperature, current, voltage, and SoC to extend the battery life and maintain safety.

Renewable energy systems (solar, wind, etc.): In renewable energy systems, BMS are used to manage the storage and distribution of the energy produced. They help to optimize the performance of the storage system, ensuring that the maximum amount of energy is stored and available for use when needed.

Energy storage systems (residential, commercial, grid-scale): BMS in energy storage systems are essential for monitoring and controlling the charge and discharge cycles, ensuring that the stored energy is used efficiently, and prolonging the life of the battery.

Industrial and marine applications: BMS in industrial and marine applications are used to manage large battery banks, ensuring optimal performance, reliability, and safety. They are responsible for monitoring various parameters such as temperature, voltage, and current, and protecting the battery from potential hazards.

Telecom and data center backup power systems: BMS in telecom and data center backup power systems ensure that the batteries are in good condition and ready to provide backup power when needed. They monitor the battery’s health, charge level, and other parameters to maintain optimal performance and reliability.

BMS VS Similar Systems

Contrasting BMS with Battery Monitoring Systems (BMoS)

Battery management systems (BMS) and battery monitoring systems (BMoS) are designed for monitoring the battery status. However, BMS includes battery management, charging, and discharging operations, and usually contains more functions and modules, such as battery balancing and fault detection.

Comparing BMS to Battery Energy Storage System (BESS)

Both energy storage systems (BESS) and battery management systems (BMS) serve the purpose of storing energy. We typically refer to BESS as a larger system capable of handling higher power inputs and outputs. Additionally, BESS usually incorporates more complex control algorithms and higher scalability, enabling larger-scale and multi-storage system applications.

Differences Between BMS and Battery Protection Circuit Modules (PCM)

We use the battery protection circuit module (PCM) as a safety circuit board to protect a single battery or battery pack. We mainly use PCM together with a single battery or battery pack. It typically contains only basic functions such as overcharge and over-discharge protection, unlike the battery management system (BMS). BMS, on the other hand, provides more comprehensive battery management and control functions, such as battery balancing and fault detection. It can provide more comprehensive monitoring and management of the battery pack.

BMS Battery Management System Implementation

Choosing the right BMS for a specific application involves evaluating factors such as energy storage required operating time, and temperature. It is crucial to ensure that the BMS functions and performs well enough to meet specified requirements. Installation and integration of BMS require consideration of factors such as battery type, communication protocols, battery layer, and ventilation. To ensure efficient signal transmission and overall reliability of the system, it should be appropriately integrated with other components.

Proper calibration and configuration of BMS parameters are also crucial for system performance. To ensure the accuracy and reliability of the system, it is necessary to calibrate and configure BMS parameters correctly with battery parameters. Regular monitoring, maintenance, and testing are key to maintaining non-em stable and efficient operation of the BMS system. This includes continuous monitoring and periodic calibration of battery performance, temperature, and capacity to quickly identify and resolve any issues.

Besides, compliance testing and certification can ensure that BMS systems comply with international and industry standards. These enhance the quality and reliability of the system and reduce potential risks caused by BMS system failures.

BMS Battery Management System Market and Industry Trends

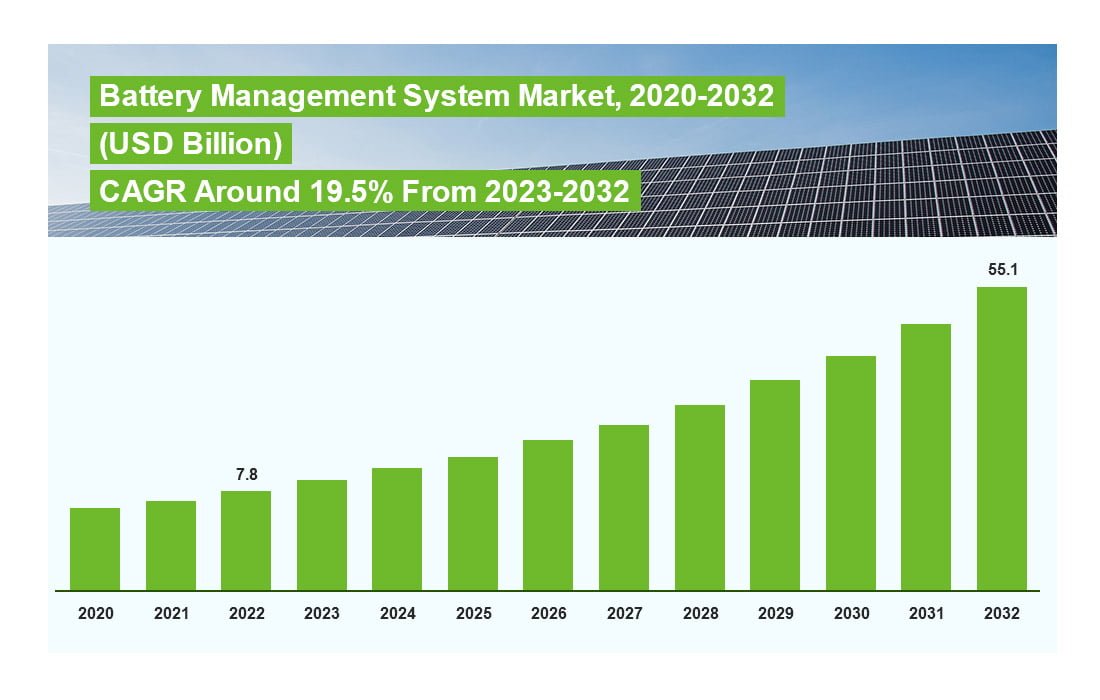

A Continuously Expanding Market of BMS

Due to the advancements in BMS technology, its application fields continue to expand. Emerging trends and innovations in battery management system technology include intelligence, remote monitoring and control, and multi-energy collaborative optimization. Furthermore, there are emerging uses, such as battery health monitoring and optimization, which rely on technologies like big data and artificial intelligence.

The market scale of battery management systems is constantly expanding, mainly due to the increase in applications in emerging fields and continuous technological advancements. Currently, global electric vehicles, renewable energy storage, and power grid systems are important markets for battery management systems.

Market growth and forecasts estimate that the battery management system market scale will continue to grow rapidly in the coming years. The Global Battery Management System Market Size in 2022 stood at USD 7.8 Billion and is set to reach USD 55.1 Billion by 2032, growing at a CAGR of 19.5%.

Top Manufacturers in the BMS Industry

These sections include international large companies, local companies, and start-ups. Among them, battery suppliers, electronic component manufacturers, and system integrators are the major participants in the battery management system field.

Here are some top manufacturers in the BMS industry around the world:

- Nuvation Energy- USA

- Lithium Balance – Denmark

- MokoEnergy – China

- Victron Energy – Netherlands

- Leclanché – Switzerland

- BMS PowerSafe – France

- Saft Batteries – France

Built in 2006, MOKOEnergy devoted itself to creating perfect energy products and solutions. In the present day, MOKOEnergy provides comprehensive services as a complete solution provider for BMS. These services encompass OEM, ODM, and DFM, covering the entire process from design and integration to component selection, assembly, and testing. Our expertise lies in designing, producing, assembling, and thoroughly testing BMS Battery Management Systems to guarantee optimal safety and reliability. Our BMS battery management system is not only flexible and of high quality, but also at a competitive price. This is why more and more customers choose MOKOEnergy.

BMS Battery Management System Challenges and Future Outlook

Limitations and Potential Challenges in BMS Implementation

Implementing BMS has limitations like battery tech, testing standards, safety, and data management. Battery tech constantly evolves, making BMS adaptation challenging. We need to improve areas like data storage and management, testing standards, and safety to ensure effective and safe use.

Trend and Prospect of BMS

Smart BMS tech research and development focuses on new battery tech, intelligent algorithms, and safer solutions. Researchers are investigating emerging applications such as battery health management, utilizing big data and AI technology. These applications are expected to undergo further development and find broader usage.

Future developments in BMS tech will improve electric vehicles, and renewable energy, promoting updated battery management. BMS development will also create new applications and models, advancing social and economic sustainability.

Choose BMS to Update Your Battery System

BMS technology has been widely used in many fields. As technology advances, BMS tech expands to various fields like industrial automation, smart homes, military, etc.

The crucial role of BMS is optimizing battery performance and safety, and maintaining battery health, longevity, and system reliability. Besides, BMS also minimizes energy loss during charging, promoting battery durability, and cost savings.

As a professional BMS Battery manufacturer, MOKOEnergy provides several types of BMS Battery Protection Boards. Our products include Power Tool BMS, Energy Storage BMS, Light EV BMS, Consumer Electronics BMS, Medical Devices BMS, and Lighting BMS. To guarantee safety and dependability, we engage in the design, production, assembly, and testing of BMS Battery Management Systems. Besides, we offer solutions for your battery. Please contact us if you need.

CONTINUE READING ABOUT THE BMS PRODUCTS