In today’s world of energy storage, Battery Management Systems (BMS) are essential for ensuring the safety, efficiency, and longevity of batteries across various applications. When it comes to lead-acid batteries, which have been a cornerstone of energy storage for decades, a Lead-Acid BMS plays a critical role in preserving battery health and performance. Whether managing energy in a solar-powered system or relying on backup power, this comprehensive guide will walk you through everything you need to know about the BMS for lead-acid battery systems.

Understanding Lead-Acid Batteries

Lead-acid batteries have been around for over 150 years and remain widely used due to their reliability, affordability, and robustness. These batteries are made up of lead plates submerged in sulfuric acid, and their energy storage capacity makes them ideal for high-current applications.

There are three main types of lead-acid batteries:

- Flooded Lead-Acid (FLA): The traditional type, often used in automotive applications, where maintenance (such as adding water) is necessary.

- Absorbent Glass Mat (AGM): A more maintenance-free version that is often found in UPS systems and renewable energy storage.

- Gel Batteries: Sealed and designed for deep-cycle applications, these are common in off-grid solar power setups, golf carts and RVs.

Despite their durability, lead-acid batteries face significant challenges like sulfation (crystal formation on lead plates) and potential overcharging or deep discharge, which can dramatically shorten their lifespan. This is where the Lead-Acid BMS comes into play.

What is a Lead-Acid BMS?

A Lead-Acid BMS is a system that manages the charge, discharge, and overall safety of lead-acid batteries. Its primary function is to monitor the battery’s condition and ensure it operates within safe parameters, ultimately extending the battery’s life and preventing failures. While Lithium BMS has become more popular with newer battery technologies, a BMS for lead-acid battery systems remains vital for industries and applications that rely on traditional lead-acid power storage.

Key Functions

- Voltage Monitoring: Ensures each cell maintains the proper voltage levels, preventing overcharging or over-discharging.

- Temperature Control: Lead-acid batteries are sensitive to temperature changes, which can impact performance. The BMS prevents overheating and helps to optimize charging efficiency.

- Current Control: Regulates the current flowing in and out of the battery to protect against short circuits or current surges.

- State of Charge (SOC) Management: This monitors how much charge remains, helping users avoid deep discharges that degrade the battery.

Components

A Lead-Acid BMS consists of several critical components that work together to manage and protect the battery:

- Voltage Sensors: These measure the voltage across individual cells, ensuring they remain balanced during charging and discharging.

- Temperature Sensors: Monitoring battery temperature is crucial to avoid thermal runaway, especially in applications where batteries are exposed to varying climates.

- Control Circuits: The BMS’s brain, which processes data from the sensors and adjusts charging parameters or issues warnings if something goes wrong.

- Balancing Circuits: Some BMS systems include balancing circuits to ensure each cell charges evenly, preventing one from overcharging and potentially damaging the battery.

How It Works

The BMS for lead-acid battery systems functions through constant monitoring and regulation during all stages of battery operation: charging, discharging, and standby.

- Charging Phase: When the battery is being charged, the BMS monitors the voltage and ensures that cells do not exceed their safe voltage limit. If one cell charges faster than others, the BMS either stops charging that cell or activates balancing circuits to redistribute energy.

- Discharging Phase: During battery use, the BMS ensures that no cell falls below its minimum voltage threshold. This prevents deep discharge, which can lead to irreversible damage and significantly reduce the battery’s lifespan.

- Standby Phase: When the battery is idle, the BMS continues to monitor the voltage and temperature to prevent any anomalies, such as unexpected discharges due to external loads or environmental conditions.

In some systems, particularly those with large battery banks, active balancing is used to transfer energy from one cell to another in real-time, while passive balancing simply dissipates excess energy as heat.

Advantages of Using a Lead-Acid BMS

Implementing a Lead Acid BMS comes with numerous advantages, enhancing both performance and safety:

- Extended Battery Life: By preventing overcharging and deep discharges, a BMS can significantly extend the life of a lead-acid battery. This is especially important in applications like solar storage, where cycling is frequent.

- Enhanced Safety: With real-time monitoring of voltage, current, and temperature, the risk of dangerous conditions such as thermal runaway, short circuits, or even explosions is minimized.

- Optimized Performance: The BMS helps balance the charge across cells, ensuring the battery operates at peak efficiency and providing consistent power output.

- Lower Maintenance Costs: Since the BMS prevents common issues like sulfation, which usually requires expensive maintenance or even battery replacement, it reduces the overall cost of ownership.

Common Challenges and Limitations

While a BMS for lead-acid battery systems offers significant benefits, there are also some challenges:

- Sulfation:Despite the best efforts of a BMS, lead-acid batteries are prone to sulfation, particularly if left in a discharged state for too long. This crystallization can reduce capacity over time.

- Temperature Sensitivity:Lead-acid batteries can be sensitive to extreme temperatures, and the BMS must carefully monitor and adjust charging to avoid degradation in cold or hot environments.

- Weight and Size:Lead-acid batteries are heavier and larger than modern lithium alternatives. Even with a BMS, these factors can limit their use in space-constrained applications.

Additionally, Lead-Acid BMS systems are typically more simplistic compared to their lithium counterparts, due to the less complex nature of lead-acid chemistry. This may limit their effectiveness in highly demanding or mission-critical environments.

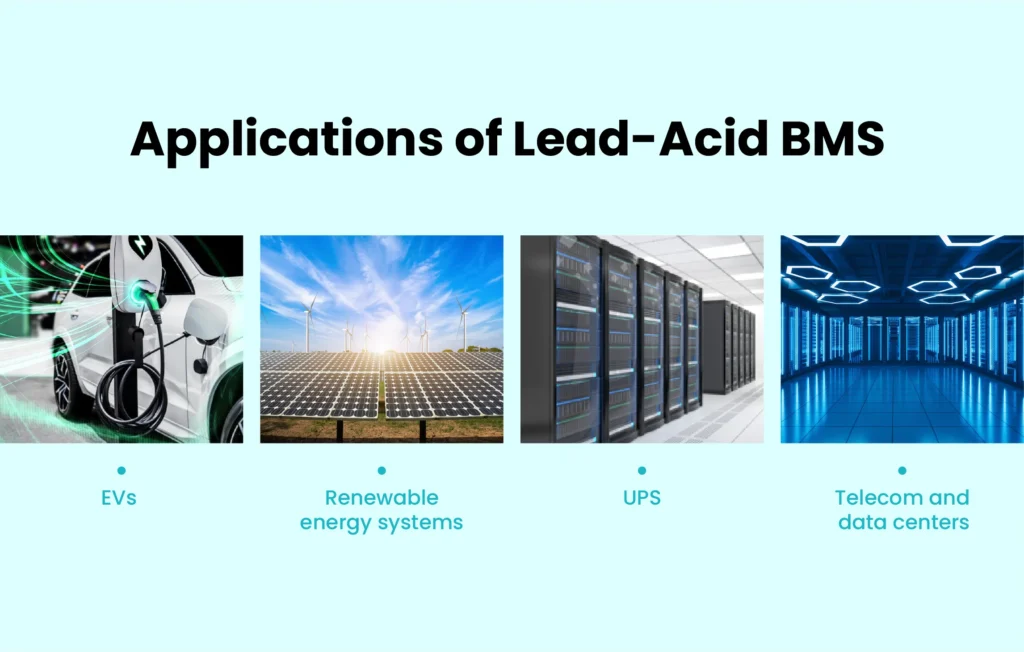

Applications of Lead-Acid BMS

Lead-acid batteries, when paired with a BMS, are integral to several key industries that depend on reliable, cost-effective energy storage solutions. Here’s a look at the primary sectors where a Lead-Acid BMS plays a crucial role:

Automotive Industry: Lead-acid batteries are commonly used in vehicles for starting, lighting, and ignition (SLI) functions. In electric vehicles (EVs) and hybrid models, they act as auxiliary batteries to power onboard electronics. A BMS ensures optimal performance by preventing overcharging or undercharging, thus enhancing battery lifespan and vehicle reliability.

Renewable Energy Systems: Lead-acid batteries are widely utilized in solar and wind energy storage systems due to their affordability and reliability. In these setups, a Lead-Acid BMS ensures efficient energy storage, regulates charge levels, and protects the battery from over-discharge, which is crucial for maintaining consistent power output during periods of low energy generation.

Uninterruptible Power Supplies (UPS): In critical power backup systems like UPS units, lead-acid batteries provide emergency power during outages. A BMS monitors the battery’s state of charge and ensures that it is always ready for action, reducing the risk of downtime in mission-critical environments like hospitals, data centers, and industrial plants.

Telecom and Data Centers: Telecom towers and data centers rely heavily on lead-acid batteries for backup power to ensure uninterrupted services. A BMS is essential for managing large battery banks, preventing overcharging, and balancing the charge across multiple cells to ensure optimal performance and longevity in these high-demand environments.

Choosing the Right Lead-Acid BMS

Selecting the appropriate Lead-Acid BMS for your system depends on several factors:

- Battery Capacity: The BMS must be rated for the capacity and voltage of the battery bank it’s managing.

- Application Type: Different applications, such as automotive vs. renewable energy, have specific requirements for voltage regulation, balancing, and temperature management.

- Communication Protocols: Some advanced BMS systems support communication protocols like CAN Bus or Modbus, allowing remote monitoring and diagnostics.

- Additional Features: Depending on your needs, look for features like active balancing, thermal management, and data logging.

Future Trends

As technology advances, Lead-Acid BMS systems are becoming more sophisticated. Some of the future trends include:

- Smart BMS Integration: BMS systems with IoT integration can remotely monitor battery health, send alerts, and even predict failures before they occur, improving overall system reliability.

- Advanced Balancing Techniques: New methods of balancing may emerge, improving the performance of large lead-acid battery banks by minimizing the risk of unequal charge distribution.

Conclusion

In summary, a Lead-Acid BMS is an essential tool for anyone relying on lead-acid batteries, providing safety, reliability, and performance improvements. At MOKOEnergy, we offer advanced BMS solutions tailored to your specific needs. Contact us today to find out how our BMS systems can optimize your battery setup and help you achieve the best results for your energy storage applications.