Batteries are applied in many things from electric vehicles to renewable energy solutions. However, without a reliable battery management system, these batteries can become a ticking time bomb. If you want to ensure your battery safety and optimal performance, a BMS is necessary. So, what do you need to know while BMS installation? Let’s deep into this field and learn how to install a BMB on your batteries and keep your devices running smoothly and safely.

What is a BMS (Battery Management System)?

A battery management system (BMS) is an electronic control unit that oversees and regulates the operation of rechargeable batteries, whether individual cells or entire battery packs. Its primary functions include:

- Monitoring battery parameters like cell voltages, temperatures, and currents

- Protecting batteries from overcharging, overdischarging, and excessive current

- Balancing cell voltages to ensure consistent performance

- Providing state-of-charge (SOC)and state-of-health (SOH) estimates

- Communicating with external devices or systems

BMS units are essential components in large-scale battery systems, finding widespread use in electric vehicles, renewable energy storage solutions, and other applications relying on high-capacity battery packs.

How to Install a BMS to Batteries

It is easy to install a BMS to the batteries. Installing a BMS on battery packs is a crucial process that requires careful planning and execution. Here’s a general step-by-step guide:

Step 1: Gather materials

Gather the necessary tools and materials, including the BMS unit, wiring harnesses, connectors, and insulation materials.

Step 2: Prepare battery packs

Prepare the battery pack by ensuring proper cell arrangement and spacing.

Step 3: BMS Wiring (This part will be explained in detail in the next section)

Connect the BMS to the battery pack according to the manufacturer’s instructions, ensuring proper wiring and connections.

Step 4: Install Sensors if Necessary

Install temperature sensors (if applicable) at strategic locations within the battery pack.

Step 5: Power Connecting

Connect the BMS to the external power and communication systems.

Step 6: BMS Setting

Configure the BMS settings and parameters according to the battery chemistry and pack specifications.

Step 7: BMS Testing

Test the BMS functionality and monitor the system’s performance.

Safety should always be the top priority during BMS installation. Follow proper safety protocols, such as wearing personal protective equipment (PPE) and working in a well-ventilated area.

Detail Guide of BMS Wiring in BMS Installation

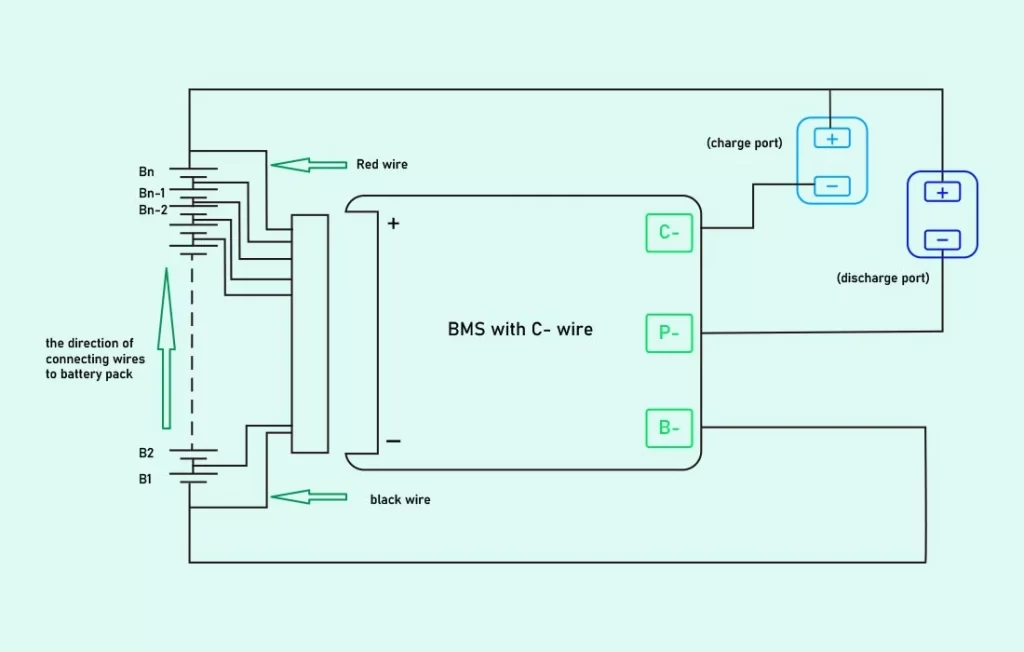

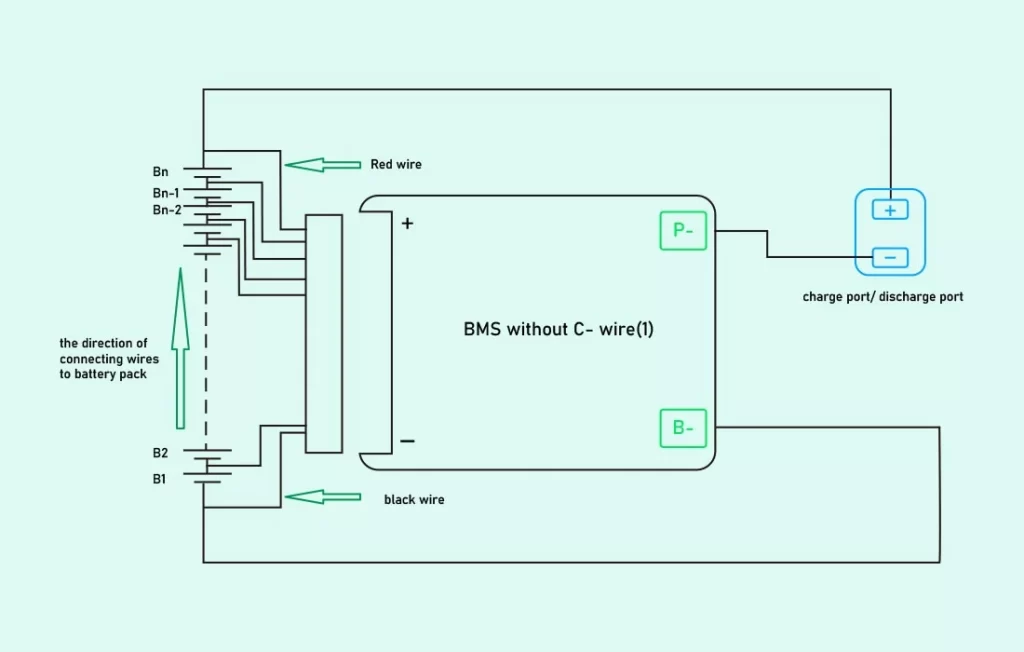

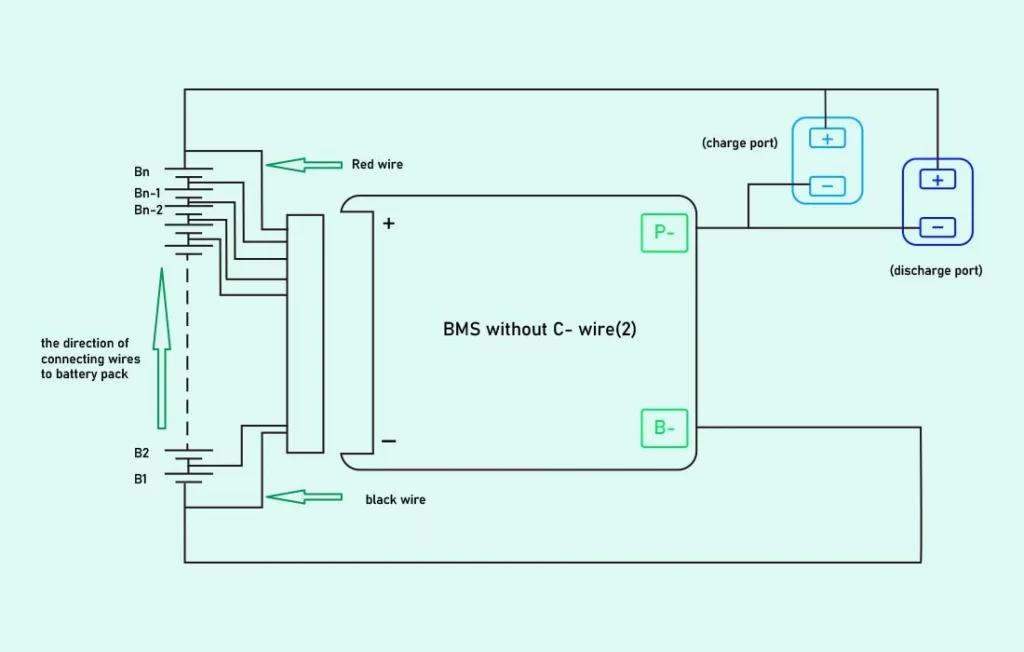

Proper BMS wiring is crucial for accurate battery monitoring and management. There are two types of typical wiring diagrams for a BMS installation: BMS with C- wire & BMS without C- wire.

The difference between them is that they connect to different ports. If you are using a BMS separate port, then you may need to connect the C- wire to the negative side of the charging connector. If you are using a Common port, there is no C-wire. And all that remains to be considered is the installation of the B- and P-wires.

BMS B- Wire Installation

If the B- wire for your BMS is not soldered to the board ahead of time, then you will need to solder it yourself. Since the B- wire connection is a high-current connection, you need to make sure that there is a large contact surface area between the wire and the pads on the BMS board. Also, you should notice that the B- wire is as short as possible. You need to be very careful when connecting the B- wire to the nickel portion between the cells. One tip is to solder the B- wire to a piece of nickel that is the same shape and size as the nickel piece on the battery. After soldering, please remember to remove any impurities from the bottom. Finally, place the pre-soldered nickel piece with the B-wire onto the negative terminal of the main battery pack and spot-weld it into place.

BMS P- Wire Installation

The P- wire will be used as the connection for charging and discharging the negative terminal of the power supply. This wire needs to be the same thickness as the B- wire. The points that need attention while soldering are the same and can be connected to the negative battery terminal using the same soldering technique using in installing B- wire. If the charge and discharge ports are the same, then the P-wire is connected to the same port. However, if the charge port and discharge port are separate, the P-wire needs to be connected to the negative terminal of the charge port and discharge port respectively. When connecting, it is better to install the connector to the charging or discharging wire first, and then connect the other end of the wire to the BMS.

Some Wiring Considerations

There are some points you need to pay attention to while wiring:

- Using appropriate wire gauges and insulation for voltage and current ratings

- Minimizing wire lengths to reduce resistance and voltage drops

- Implementing fail-safe mechanisms, such as fuses or circuit breakers

- Ensuring secure and reliable connections

Factors to Consider During BMS Installation

Several factors can impact the success and effectiveness of a BMS installation:

| Factor | Considerations |

| Battery Chemistry | Compatibility with different battery chemistries (e.g., lithium-ion, lead-acid) |

| Battery Pack Configuration | Series and parallel battery arrangements, total capacity, and voltage levels |

| Environmental Conditions | Operating temperature range, vibration, and moisture resistance |

| Power and Communication | Integration with external systems, data communication protocols |

Cost of BMS Installation

Some people will want to install their own BMS, so it is important to consider the cost of installing a BMS. It can be affected by several factors, such as the different BMS features and brands; the size and configuration of the battery pack; and additional components such as connectors and sensors. Although a DIY BMS installation may seem cost-effective at the outset, it poses a potential risk to the battery if not properly installed or maintained, and subsequent maintenance costs can increase. Therefore, it is recommended to choose a professional BMS company to provide you with assembly and installation services to ensure that the equipment can operate correctly and safely.

How to Choose The Right BMS Installation Company?

When choosing a BMS installation company, what factors will you consider? In my opinion, extensive experience and expertise in BMS installation are the first things to consider. Other factors like service offerings (installation, maintenance, troubleshooting) and industry certifications are also important.

MOKOEnergy is a leading provider of battery management systems and solutions. Their BMS offerings include:

- Advanced monitoring and protection features

- Customizable configurations for various battery chemistries and pack sizes

- User-friendly interface and configuration tools

- Robust communication protocols and integration capabilities

Whether you choose to pursue a DIY installation or engage professional services, prioritizing safety and following best practices is paramount. With reputable companies like MOKOEnergy offering comprehensive BMS solutions, you can have peace of mind knowing your battery systems are in good hands.

Take the first step towards reliable and efficient battery management by exploring MOKOEnergy’s BMS offerings or contacting a trusted BMS installation company today.