The popularity of lithium-ion batteries has led many people to choose lithium batteries. However, lithium batteries can not be used without a suitable battery management system (BMS), to choose the right battery protection board, we must remember the following points: their components, functionality, types, selection considerations, applications, installation guidelines, advancements, and future trends.

What is a Battery Protection Board?

Battery protection board, i.e. the circuit board that plays a protective role. It is mainly composed of electronic circuits, which can accurately monitor the voltage of the battery cell and the current of the charging and discharging circuits at any time under the environment of -40℃ to +85℃, and control the on-off of the current circuits in time.

Common lithium battery protection board usually includes a control IC, MOS switch, resistor, capacitor, and some auxiliary devices. Among them, the control IC controls the MOS switch to make the battery cell and the external circuit conductive under normal conditions. When the voltage of the battery cell or the current of the circuit exceeds the specified value, it immediately controls the MOS switch to shut down to protect the safety of the battery cell.

Essential Components of Battery Protection Board

Battery protection boards consist of several essential components that enable their functionality:

Voltage Monitoring: These boards continuously monitor battery voltage to prevent overcharging and over-discharging. The voltage thresholds for activating protection measures typically range from 4.2 volts per cell (for overcharging) to 2.5-3.0 volts per cell (for over-discharging).

Current Sensing: Battery protection boards detect excessive current flow and short circuits, protecting the battery and the electronic device. Current sensors are designed to handle specific current ranges, such as 10A, 20A, or higher.

Temperature Monitoring: These boards monitor battery temperature to prevent overheating. The temperature thresholds triggering protection mechanisms usually range from 60 to 80 ℃ (140-176 ℉).

Cell Balancing: In multi-cell battery packs, battery protection boards ensure voltage balance among the cells. Cell balancing operates within a voltage range of approximately 3.6-4.2 volts per cell, depending on the battery chemistry.

Overcurrent Protection: Battery protection boards implement current limiting measures to prevent excessive current draw. The specific current limits and response times vary based on the board’s design and application requirements.

Types of Battery Protection Boards

There are several types of battery protection boards available, designed to cater to different types of batteries and specific protection requirements. Here are some common types:

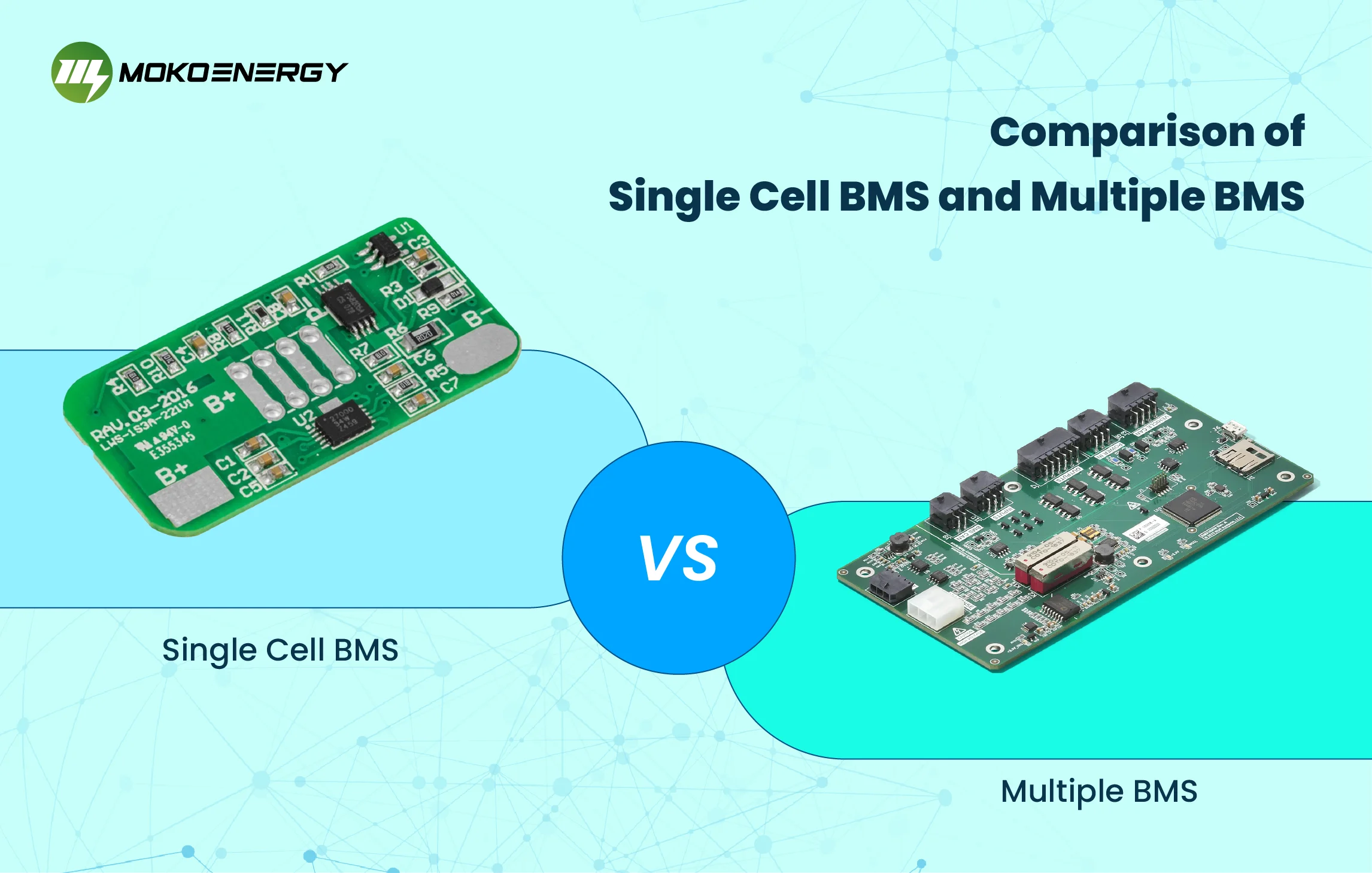

Single-cell Protection Boards: These boards are designed for applications that use a single battery cell, such as smartphones and wearables. They support battery chemistries like lithium-ion (Li-ion) or lithium-polymer (LiPo) with voltage ranges typically from 3.7 to 4.2 volts.

Multi-cell Protection Boards: Multi-cell protection boards are suitable for battery packs with multiple cells, such as those used in electric vehicles (EVs) or energy storage systems. They accommodate various battery chemistries and voltage ranges, such as Li-ion battery packs with voltages ranging from 7.2 to 48 volts or higher.

LiFePO4 Battery Protection Board: Lithium Iron Phosphate (LiFePO4) batteries have different voltage characteristics compared to Li-ion or LiPo batteries. LiFePO4 battery protection boards are specifically designed for these batteries, offering appropriate protection and voltage detection for LiFePO4 chemistry.

Lead-Acid Battery Protection Board: Lithium-based batteries exhibit distinct charging and discharging behaviors in contrast to lead-acid batteries, which are frequently employed in automotive and stationary power systems. Battery protection boards for lead-acid batteries are designed to ensure the safe and efficient operation of these batteries.

Smart Battery Protection Board: Smart battery protection boards incorporate advanced features like communication interfaces (e.g., I2C, SPI) and built-in monitoring and control capabilities. They allow for more precise control, data logging, and integration with external systems or microcontrollers.

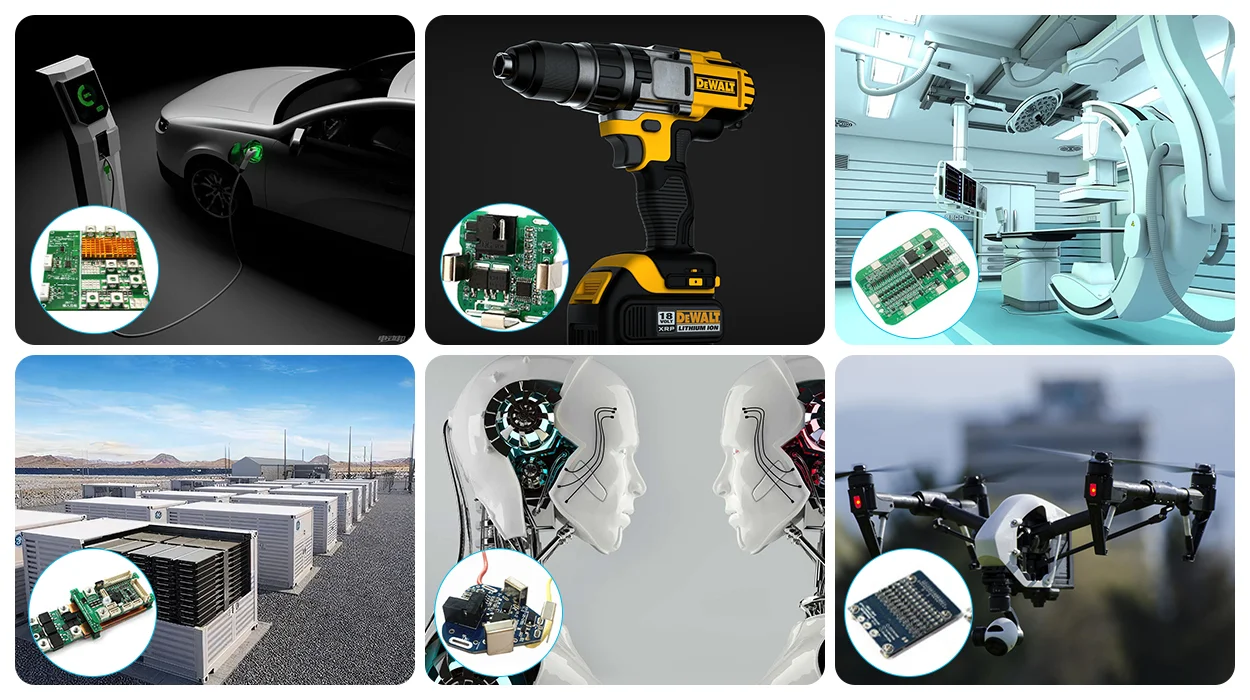

Where Are Battery Protection Boards Used?

Electric Vehicles (EVs) and Hybrid Vehicles: Battery protection boards are essential for managing and protecting the batteries used in electric and hybrid vehicles, ensuring their safety, efficiency, and lifespan.

Power Tools: Battery-powered tools like drills, saws, and power banks incorporate battery protection boards to prevent damage due to overcharging, over-discharging, or high-current demands. They enhance safety and extend the battery life for longer-lasting tool operation.

Energy Storage Systems: Battery protection circuit boards have a vital function within energy storage systems that incorporate renewable energy sources such as solar or wind power. They optimize energy utilization, prevent damage to the batteries, and ensure efficient operation.

Medical Devices: Battery-powered medical devices rely on battery protection boards to maintain safe and uninterrupted operation. These boards protect against voltage irregularities, overcurrent situations, and temperature fluctuations, ensuring patient safety and device functionality.

Robotics: Battery protection boards are used in robotic applications to protect the batteries from voltage spikes, overcurrent situations, and abnormal temperature levels. They help maintain the stability and reliability of the robot’s power source.

Drones and UAVs: Battery protection boards are essential in unmanned aerial vehicles (UAVs) and drones to monitor battery voltages, prevent over-discharging, and protect against excessive current draw during flight, ensuring flight safety and maximizing battery life.

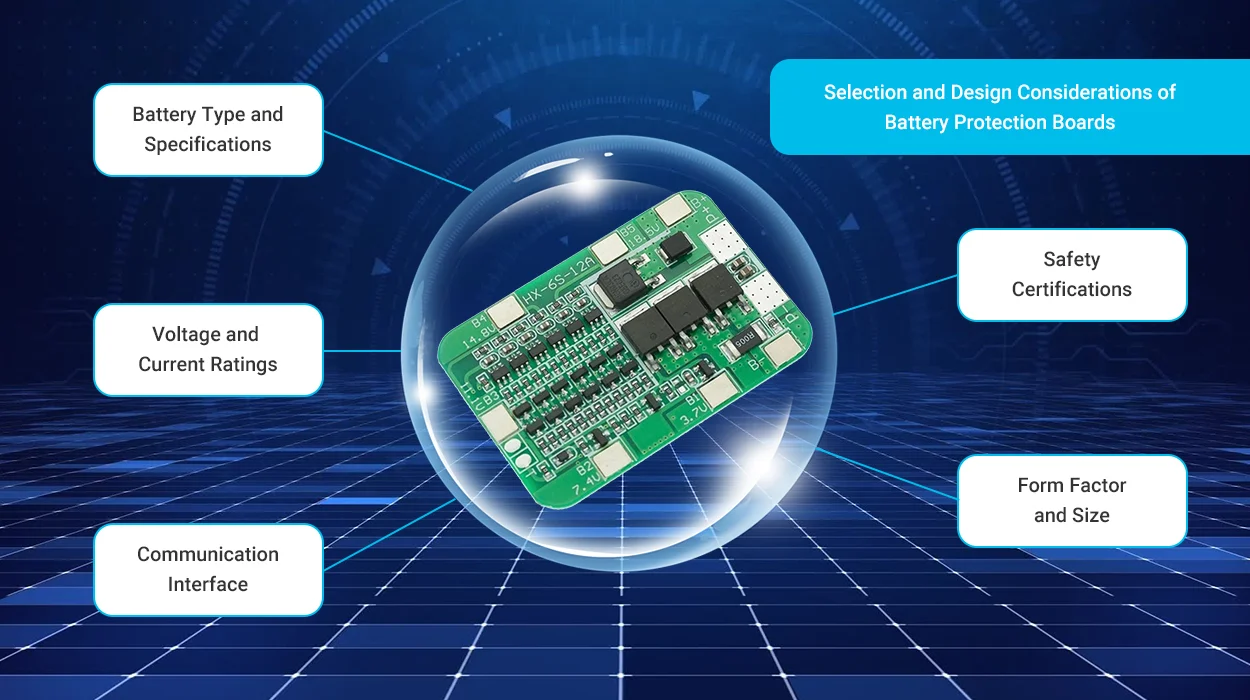

Selection and Design Considerations of Battery Protection Board

- Battery Type and Specifications

Identify the specific type of battery you will be using, such as lithium-ion (Li-ion), lithium-polymer (LiPo), lead-acid, or others. Understand the voltage range, capacity, and charging/discharging characteristics of the battery to select or design a protection board that aligns with its requirements.

- Voltage and Current Ratings

Determine the voltage and current ratings required for your application. Select a BMS battery protection board that can handle the maximum voltage and current levels expected during charging and discharging.

- Communication Interface

Determine if you require a lithium battery BMS protection board with a communication interface (e.g., I2C, SMBus). This allows for advanced monitoring, control, and integration with external systems or microcontrollers. Choose a board with the appropriate communication interface based on your application needs.

- Safety Certifications

Check whether the battery protection board possesses any safety certifications or adheres to industry standards. This will guarantee that the board has undergone thorough testing and fulfills the essential safety prerequisites.

- Form Factor and Size

Consider the physical dimensions and form factor of the protection board. Make sure that it can be accommodated within the available area in your specific application or battery pack. Some boards are available in different sizes or form factors to accommodate various applications.

Advancements and Future Trends of Battery Protection Board Technology

BMS protection board technology continues to advance, offering new features and addressing emerging challenges. Some noteworthy advancements and future trends include:

Intelligent Protection Boards: Battery protection boards are becoming increasingly intelligent, incorporating features such as predictive analytics, real-time monitoring, and adaptive protection algorithms. These advancements enhance performance, optimize battery usage, and improve overall system efficiency.

Wireless Charging Integration: Battery protection boards are being integrated with wireless charging technology, simplifying and enhancing the charging experience while ensuring seamless safety measures.

Miniaturization and Increased Energy Density: Battery protection boards are designed to accommodate the miniaturization trend in electronics. This allows for the development of smaller, more compact devices with increased energy density, meeting the demands of portable and wearable applications.

Impact on Emerging Technologies: Lithium-ion battery protection board will continue to play a significant role in emerging technologies such as electric aircraft, smart grids, and Internet of Things (IoT) devices. These boards enable safe and efficient power management in these innovative applications.

Where to Buy Battery Protection Board

In the previous section of the article, we introduced what a battery board is, its main functions and applications, as well as the factors to consider when selecting a suitable battery protection board. So, where can you buy satisfactory battery protection boards? It is important to choose a reliable supplier who can recommend suitable battery protection boards based on your work requirements, patiently explain the relevant product features and performance, and provide timely after-sales support when you encounter any product-related issues.

In my opinion, MOKOEnergy is such a trustworthy high-quality supplier. With 17 years of experience in a range of smart BMS-related electronic components, including battery protection boards, MOKOEnergy has a solid reputation. Now, let’s take a look at the key features of the popular MOKOEnergy battery protection board series:

- Precise Wiring: The lithium battery protection board features a precise PCB design, ensuring accurate and clear wiring connections.

- Versatile Application: The integrated battery BMS PCB board is specifically designed for lithium battery testing, allowing for easy identification of correct cable connections.

- Easy to Use: The lithium battery PCB protection board module offers hassle-free installation and usage, eliminating the need for complex wiring processes and enabling a simple and fast setup.

- Rapid and Safe Charging: Incorporates an intelligent lithium cell management IC that facilitates fast and secure charging of the battery.

- Comprehensive Protection: Provides a range of protection functions, including safeguards against overcharge, over-discharge, short battery protection circuit, and temperature fluctuations.

- Efficient Heat Dissipation: Equipped with thickened aluminum fins, the protection board enables efficient heat dissipation, resulting in optimal performance. The product undergoes rigorous load and aging tests to ensure superior quality.

By opting for a reliable provider such as MOKOEnergy, you can trust in the excellence and effectiveness of the battery safeguard boards they provide.

Conclusion

Battery protection boards are vital components for ensuring the safe and optimal performance of electronic devices powered by batteries. Understanding their components, functionality, types, selection considerations, and installation guidelines is crucial for selecting the right board for specific applications. Battery protection technology continues to evolve, with intelligent features, wireless charging integration, miniaturization, and increased energy density driving future trends.

As a reputable supplier, MOKOEnergy offers high-quality battery protection boards, customizable solutions, and expert manufacturing capabilities to meet the diverse needs of customers across various industries. If you need a customized solution or have other questions, feel free to contact us anytime!

CONTINUE READING ABOUT THE BATTERY PROTECTION BOARD