Understanding the Li-ion BMS design requires a basic and advanced understanding of its construction and functional principles.

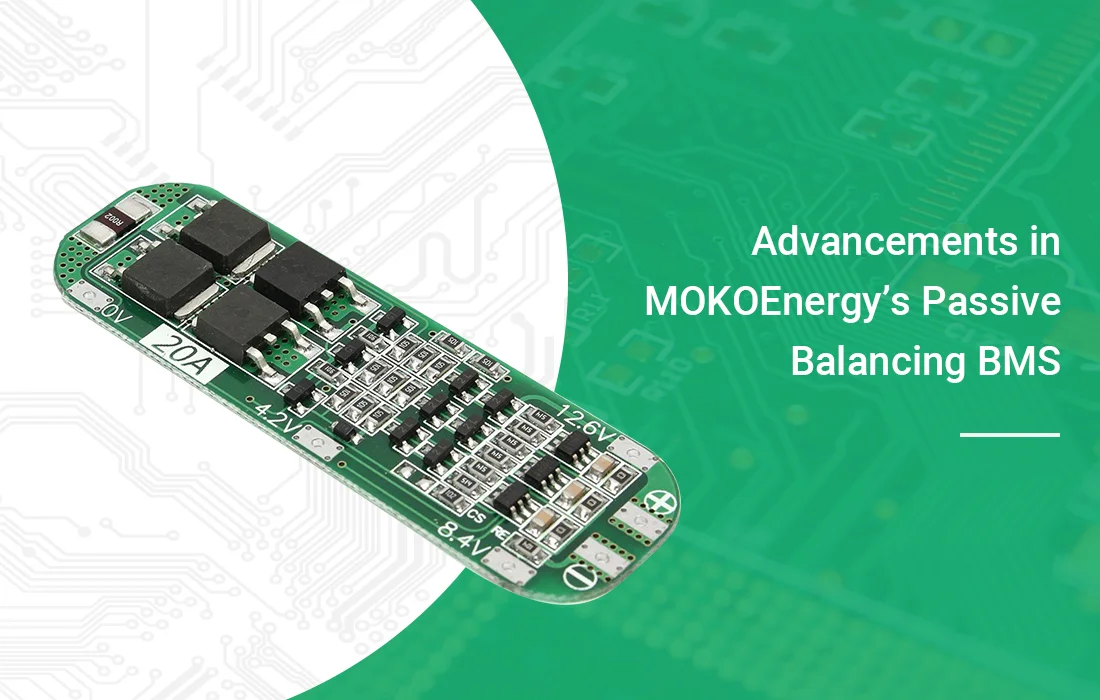

- Each different lithium-ion chemical will have different maximum and minimum voltage Settings. Therefore, BMS design must be adapted to each type of chemical. In some chemicals (and agents), the rate of charging and/or discharging is limited. Therefore, the BMS needs to allow the user to program these restrictions.

- Since the higher the temperature of the battery, the more degradation of the lithium-ion battery will occur, the BMS needs to monitor the battery temperature to adjust the charge/discharge rate to avoid exceeding the preset temperature. If the temperature is too low, then charging may damage the battery (usually at 0°C or lower). Firing below a certain temperature can also damage cells. Therefore, the BMS needs to limit these behaviors.

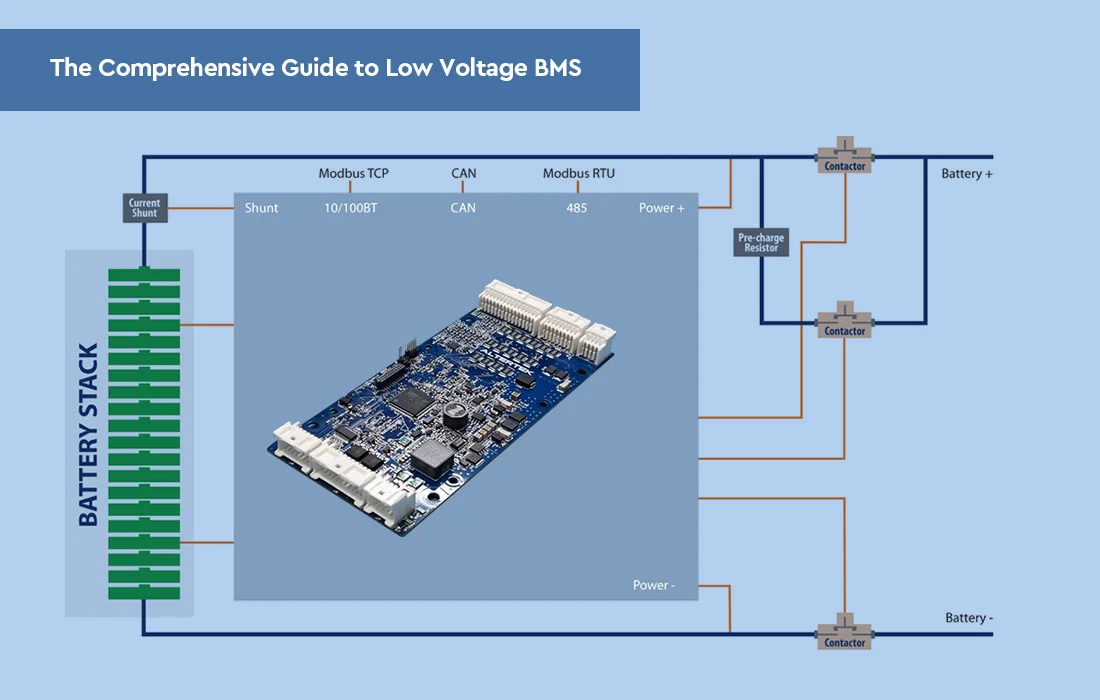

- More advanced designs will accommodate more complex powertrain arrangements; Examples include many subgroups of parallel and series battery connections; Battery balance, etc. Finally, safety. Ensure that ISO-26262 is used to design the circuit; D level is preferred.

MORE: How can we ensure cost savings as we gradually expand the battery management system?