If you are a battery manufacturer or have some knowledge about rechargeable batteries, then you must be well aware of the relationship between the Battery and the BMS. The Battery serves as the power source for devices like portable gadgets to electric vehicles and renewable energy systems, etc. On the other hand, the BMS plays an important role in ensuring the efficient, safe operation, and long lifespan of these batteries. One of its key tasks is to balance the battery cells, a critical process that guarantees uniformity and optimal performance. In this article, we will guide you on how many balancing currents are required in different applications for enhancing battery performance and safety in various scenarios.

Why Balancing Current is an Important Role in a BMS?

The BMS serves as an intelligent electronic system responsible for monitoring and managing various aspects of a rechargeable battery, including voltage levels, current flow, temperature, and State of Charge (SoC). Among its essential functions, balancing battery cells emerges as a crucial task.

The role of the BMS balancing current is to equalize the State of Charge (SoC) of individual cells within a battery pack. By achieving this balance, all cells reach the same SoC during the charging and discharging cycles. As a result, the battery’s charge capacity is optimized, allowing it to deliver maximum power, constrained only by the cell with the lowest capacity.

A balanced battery exhibits a harmonious state where all cells are precisely at the same SoC level. This balance can be achieved at any SoC level, although batteries frequently charged to full capacity often balance at 100%.

4 Types of Cell Imbalances

Battery cells can experience various types of imbalances, and resolving these imbalances is essential for optimal performance. The main types of cell imbalances are:

Actual State of Charge (SoC): Variations in the charge level of individual cells.

Leakage (Self-discharge Current): Differences in the rate at which cells lose their charge when not in use.

Internal Resistance: Variations in the resistance of the cells, affect their charge and discharge characteristics.

Capacity: Differences in the overall capacity of individual cells.

Balancing primarily targets the first type of imbalance by equalizing the SoC of cells. It also provides some compensation for variations in self-discharge (leakage) current among cells. However, capacity imbalances are managed through another technique known as Redistribution.

Why Maintaining a Balancing Current is Necessary for Your Battery?

Maintaining uniform cell capacities within a battery pack is paramount for efficient performance, especially when using cells from different manufacturers that might exhibit significant variations. While cells from top-notch manufacturers may require minimal balancing due to closer matching, those using cells from multiple manufacturers could benefit from extensive balancing to achieve optimal performance.

Cell balancing current ensures that each cell receives an equal share of charging and discharging, preventing overcharging and over-discharging of cells with higher capacities while avoiding undercharging weaker cells. This balance not only extends the battery’s lifespan but also promotes safety by mitigating the risk of cell failures.

Balancing vs. Redistribution

While balancing addresses the SoC of individual cells, it does not directly handle capacity imbalances. However, Redistribution optimizes the battery’s energy utilization by transferring charge between cells during charging and discharging. Unlike balancing, Redistribution requires higher currents to ensure all cells are fully utilized.

Balancing and Redistribution work in tandem to optimize battery performance. Balancing ensures that all cells contribute equally to the battery’s capacity, while Redistribution allows the battery to operate at its full capacity, unrestricted by any single cell.

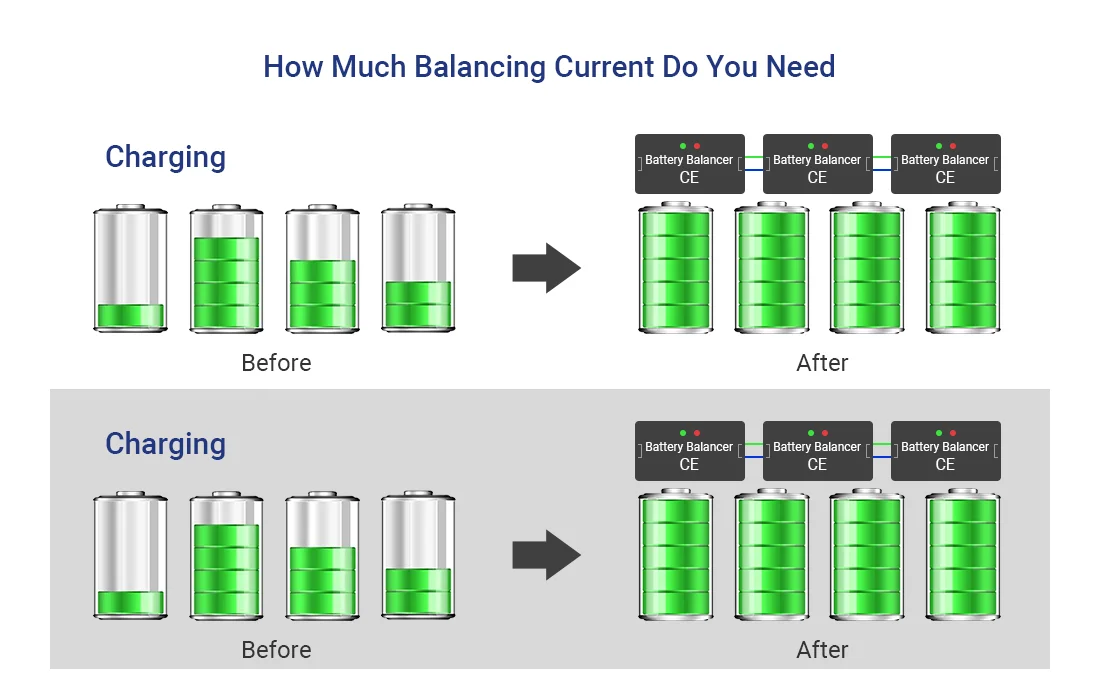

Determining the Right Cell Balance Current

The required balance current depends on the specific scenario and purpose of balancing:

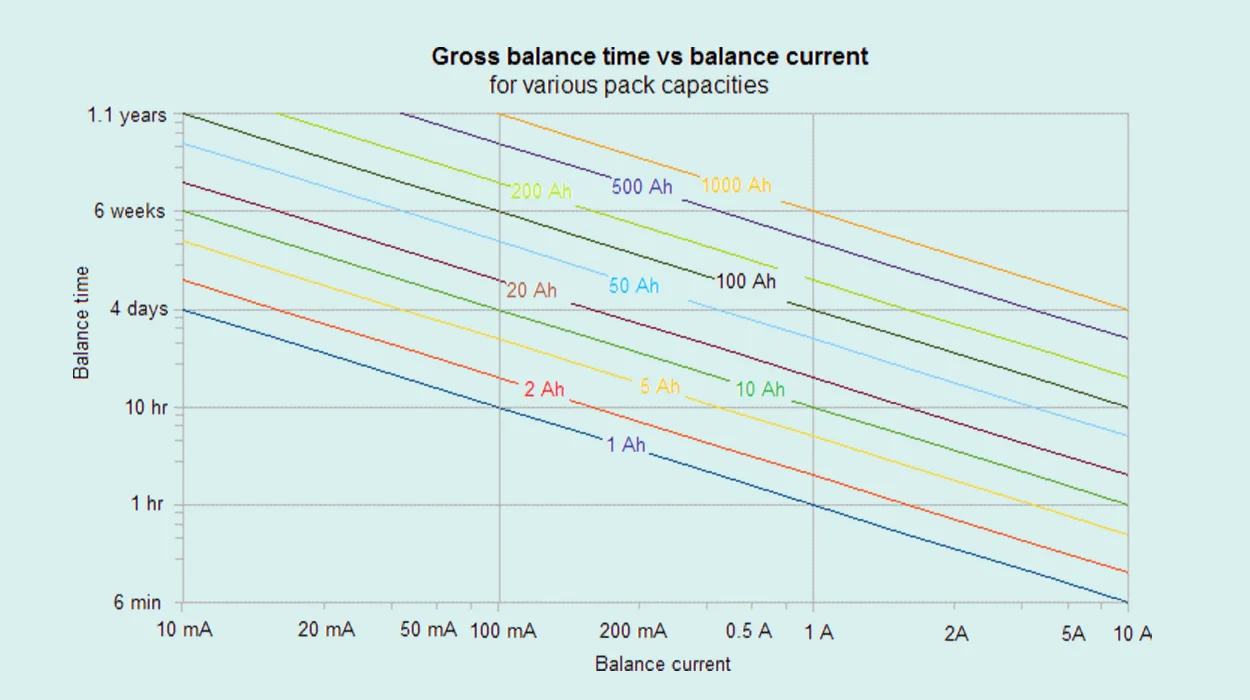

Gross Balancing:

Gross balancing is necessary when assembling or repairing a battery pack using mismatched cells. Ideally, manufacturers should build or repair packs in a balanced state, reducing the need for gross balancing. This can be achieved through balancing before build (using cells with the same SoC) or balancing after build (applying a load or supply to individual cells to adjust their charge).

The balance current required for gross balancing depends on the pack’s size and desired balancing time. Larger packs or shorter balancing times demand higher balancing currents.

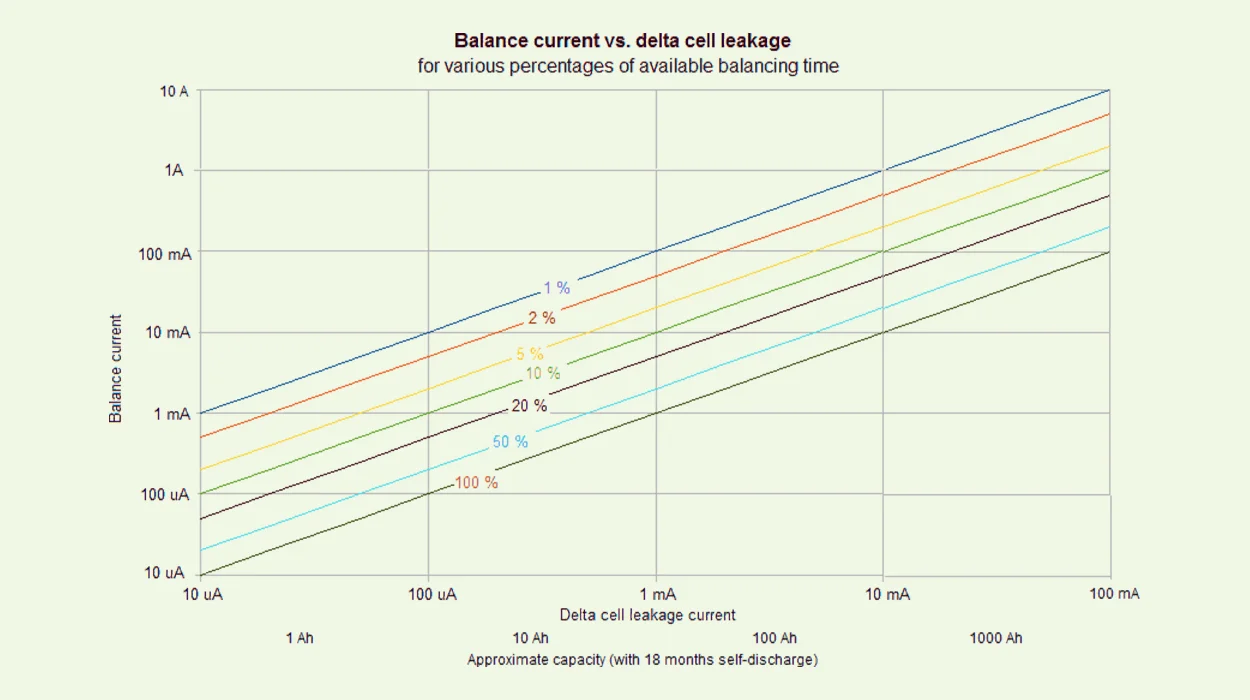

Maintenance Balancing:

Maintenance balancing is essential to keep a pack in balance during normal usage. In this scenario, the BMS compensates for variations in self-discharge leakage in the cells. The required cell balanced current depends on the difference in leakage current and the available balancing time. As some BMS systems may not be able to balance 24/7, higher balance currents are necessary to compensate for the available balancing time.

Smarter Algorithms for Enhanced Cell Balancing

Sophisticated BMS systems employ intelligent algorithms to optimize balancing efficiency. By continuously balancing whenever the pack is plugged in, BMS systems increase the available balancing time, enhancing their balancing capability without hardware upgrades.

Continuous battery balancing allows BMS systems to handle packs with higher leakage currents without compromising performance. The intelligent algorithms enable BMS systems to achieve higher balance currents by adjusting the balance duration or duty cycle to match the cells’ leakage delta current.

Choosing the Right Battery Balance Current for Different Applications

To determine the appropriate balance current for a specific application, key factors such as pack size, leakage current, and available balancing time must be considered. Here are some general rules of thumb to estimate the required balance current for Li-Ion packs in various scenarios:

- Small Backup Supply Applications (10 kWh):

A balanced current of 10 mA is sufficient. - Large Applications (100 kWh):

100 mA balance current is required for efficient maintenance balancing. - Automotive Applications (10 kWh, Plugged in Nightly):

100 mA balance current is sufficient for consistent balancing. - Large Pack Applications (>100 kWh, Cycled Daily):

A balanced current of 1 A is necessary for effective maintenance balancing.

| Application | Required Balance Current (mA) |

| Small Backup Supply (10 kWh) | 10 |

| Large Applications (100 kWh) | 100 |

| Automotive (10 kWh, Nightly) | 100 |

| Large Pack (>100 kWh, Daily) | 1000 |

Conclusion

Battery Balancing current is the key to achieving optimal battery performance, safety, and longevity. By equalizing the State of Charge (SoC) of individual cells within a battery pack, balancing ensures uniform cell capacities and mitigates cell failures. The combined efforts of balancing and redistribution enable batteries to operate at their full capacity, unrestricted by any single cell.

Manufacturers must strive to build and repair packs in a balanced state to minimize the need for gross balancing. Intelligent algorithms in BMS systems enhance balancing efficiency, enabling continuous balancing and efficient handling of packs with higher leakage currents.

Understanding the appropriate balance current for different applications is essential to optimize battery performance and ensure the efficient utilization of rechargeable batteries across various industries.

At MOKOEnergy, we are dedicated to developing cutting-edge BMS solutions that empower the future of sustainable energy storage. Our advanced BMS technology ensures efficient balancing, extending battery life, and enhancing overall system performance. With a focus on innovation and sustainability, we aim to revolutionize the way the world uses and manages energy. Reach us if you need to talk with an energy management expert!