As the new energy market expands increasingly, efficient energy storage solutions have been regarded as the most important sector. The Master-Slave Battery Management System (BMS) is an innovation that seamlessly combines performance, safety, and sustainability. Read on to learn more about the master-slave BMS architecture, and the basic installation components, and then get to know how to choose the right master-slave BMS board.

Master Slave BMS Architecture

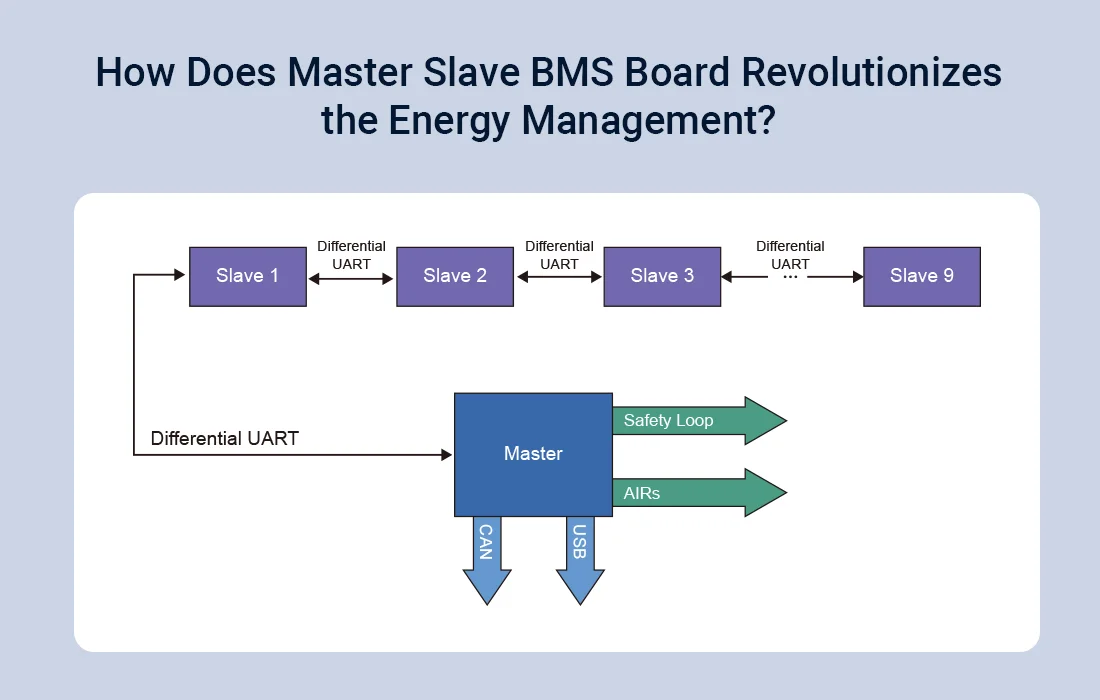

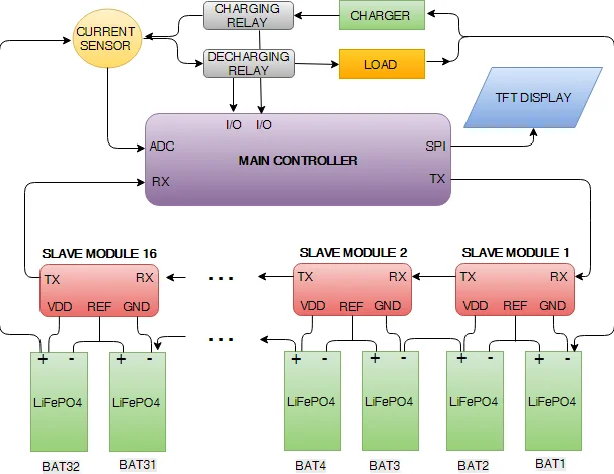

The core of the master-slave BMS architecture is a well-designed framework that coordinates energy management with unparalleled efficiency and security. This architectural marvel is based on collaboration between the main unit, a central command center, and multiple slave units, each dedicated to monitoring and controlling a single unit or module. This good interaction enables real-time monitoring, precise energy distribution, and enhanced safety within the battery pack.

Going deep into the heart of this architecture, the master unit emerges as the conductor, orchestrating the energy ensemble. With the data flowing out of the unit, it can make informed decisions about charging and discharging strategies. In parallel, the slave unit acts as a sentinel, continuously monitoring parameters such as voltage, current, and temperature at the individual unit level. This seamless communication between master and slave units ensures a dynamic and optimized flow of energy and information.

Components of Installing a Master-Slave BMS

The establishment of a master-slave BMS system requires the coordination of several key components that work seamlessly together.

- Relay: The Guardian Against Overcurrent

The relay acts as an “automatic switch”, using a small current to control a large current. It’s mainly used to protect the system from overcurrent by shutting off the power output when too much current is detected. - 12V Step-Down Module: Enabling Reliable Operation

The 12V step-down module provides the relay with a stable 12V operational voltage. The module is the cornerstone of BMS functionality and requires an external 12V power supply to activate the main contactor and prevent potential short circuits. - Power Cables: Essential Links

Power cables act as the bridge connecting BAT+ & LOAD+ to the main contactor terminals, ensuring smooth energy transfer. These connections enhance vigilant monitoring of battery pack and load voltages, ensuring both energy flow and data exchange. - Main Contactor: Enabling Energy Flow

The main contactor plays a central role in integrating the Master-Slave Board BMS Master. These connections enhance vigilant monitoring of the battery pack and load voltage, ensuring energy flow and data exchange. - Remote Main Contactor Installation: A Flexible Approach

For enhanced flexibility, remote main contactor installation allows terminals to connect to the board through compact cables and round terminals. This configuration enables remote monitoring while preserving the critical role of the primary contactor. - Main Negative Current Path: Precision in Monitoring

Monitoring current flow requires the main negative current path to traverse BAT- & LOAD-. A substantial shunt resistor beneath the PCB facilitates this monitoring, necessitating meticulous connections involving cable lugs and bolts.

Master-Slave BMS Network Topologies

Master slave BMS topologies are mainly divided into the following 4 categories:

- Star Topology

The star topology places a master node at the center, encircled by parallel-connected slave nodes. This configuration facilitates direct communication between each master and slave node, ensuring seamless data exchange and optimal information flow. - Bus Topology

In the bus topology, a singular main bus interconnects all nodes, encompassing both master and slave units. Shared communication wiring is embraced, with each node assigned a distinct address for precise identification. - Ring/Daisy Chain Topology

The ring or daisy chain topology involves sequential connections of slave nodes, with the master node positioned at one end. Data traverses each slave node before reaching the master node, enabling a comprehensive communication flow. - Hybrid Topology

The hybrid topology marries the strengths of preceding configurations. It accommodates multiple daisy-chained communication lines linked to the master or several star topologies intertwined into a central bus. This adaptability provides a common platform for efficient communication network design.

Advantages of master slave battery management system

Scalability: Master-Slave BMS systems can accommodate a wide range of battery pack sizes, making them suitable for various applications, from small-scale residential energy storage to large industrial setups.

Redundancy: The layered structure improves the reliability of the system. If one slave unit fails, the master unit can still operate and manage the other slave units, reducing the risk of a complete system shutdown.

Efficiency: By monitoring individual cells or modules, the BMS master slave system can optimize the charging and discharging process, thereby increasing overall efficiency and extending battery life.

Safety: Precise monitoring at the battery level allows early detection of anomalies, such as overcharging or overheating, which improves the safety of the entire battery pack.

Flexibility: The master slave BMS system can be adapted to various chemistry and types of batteries, making it suitable for different applications such as lithium-ion, lead acid, etc.

Where to use the master slave BMS board?

The versatility of Master-slave BMS technology makes it widely used:

Residential energy storage: In the home energy storage systems, master-slave BMS guarantees a reliable power supply and maximum solar self-use.

Electric Vehicles: The technology optimizes battery performance, extends driving range, and improves the overall efficiency of electric vehicles.

Renewable Energy Plants: Master-slave BMS systems play an important role in stabilizing the grid by managing the output of renewable energy sources such as solar and wind.

Telecommunications: Backup power systems for cell towers and communications infrastructure benefit from the reliability and security provided by master-slave BMS.

How to Choose an Ideal Master Slave Board?

The selection of a suitable slave board is paramount for a high-performance Master-Slave BMS system. The factors below should be taken into consideration.

- Compatibility and Integration

The chosen slave board must seamlessly integrate into the overarching BMS architecture. Compatibility with the master unit and adherence to communication protocols guarantee seamless data exchange and unfaltering system operation. - Scalability and Expandability

Scalability is key when evaluating slave board options. The chosen board should readily accommodate potential system expansions, facilitating the integration of additional battery cells or modules as needs evolve. - Data Precision and Fidelity

The capability for accurate voltage, current, and temperature monitoring is indispensable. High-resolution data acquisition guarantees informed decision-making, optimizing energy allocation and safety. - Balancing Proficiency

Effective cell balancing prolongs battery life and ensures consistent performance. The selected slave board must facilitate balancing mechanisms, enabling voltage equalization across cells. - Real-Time Communication

Efficient real-time communication between slave and master units is of paramount importance. The chosen slave board should empower rapid data transmission, minimizing latency and ensuring timely responses.

MOKOEnergy: Pioneering a Sustainable Vision

In this dynamic field, MOKOEnergy is a pioneer in the master-slave Battery management system space. As an ODM and OEM manufacturer of BMS boards, MOKOEnergy seamlessly integrates technology with practical applications to foster a greener, sustainable energy ecosystem.

Conclusion

In the relentless pursuit of energy efficiency, the master-slave BMS architecture shines as a beacon of innovation. From coordinating energy flows to protecting batteries, the BMS system points the way to a sustainable future. If you’re looking for BMS board manufacturers, then contact us and partner with MOKOEnergy!