Battery performance and safety can rapidly deteriorate when cell temperatures rise excessively high during operation and charging. This dangerous elevation in temperature is commonly referred to as overtemperature or overheating. If left unchecked, it can ultimately lead to thermal runaway — the point when a battery cell goes into meltdown with the subsequent release of electrolytes and dangerous gases. Needless to say, overtemperature scenarios must be avoided in battery packs and systems through proper safeguards. This is where battery management systems (BMS) and purposefully designed thermal management methods come into play to prevent issues and protect investments in battery storage projects across industries. In this comprehensive guide, we’ll explore key details on overtemperature protection. Read on as we delve into these topics to provide you with the knowledge to appropriately incorporate over temperature protection.

How BMS Solutions Work With Overtemperature Protection

Battery management systems are specialized electronics and software that monitor and control battery packs or arrays. BMS monitors parameters like cell voltage, currents, and yes…temperature.

In terms of overtemperature protection specifically, here is how BMS solutions excel:

- Battery Temperature Monitoring: During BMS programming and commissioning, overtemp thresholds are defined based on cell manufacturer guidelines and application demands. If monitored temperatures exceed predefined maximums, action is taken.

- Charge/Discharge Cutoff: Exceeding temperature thresholds often leads BMS to cut off charge or discharge completely to halt heating effects.

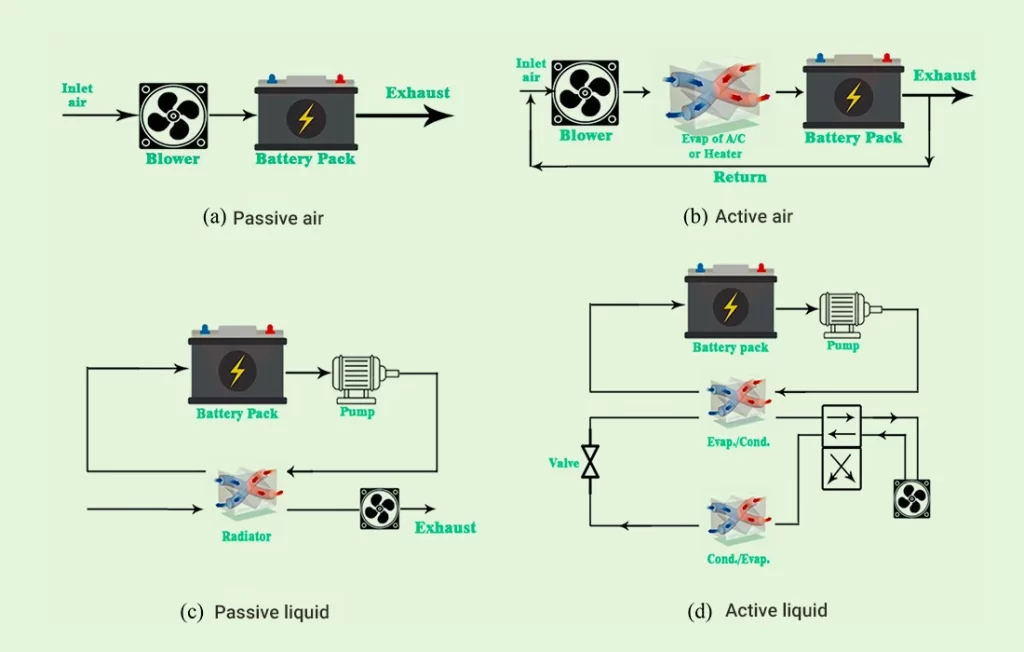

- Cooling Control: BMS can activate auxiliary cooling systems (either passive air or active refrigeration/liquid) when needed to prevent reaching critical points.

- Status Notifications: Apps and remote dashboards provide alerts when temperatures are on the rise before major issues occur.

By leveraging the automation and control functionality of BMS, over-temp scenarios can be avoided through early detection and mitigation steps. The sophistication of these protective measures scales with BMS capabilities specified.

Key Technologies in Battery Overtemperature Protection

In the relentless pursuit of ensuring the safety and optimal performance of battery systems, a multifaceted approach to overtemperature protection is imperative. This entails the integration of various cutting-edge technologies designed to mitigate thermal risks and maintain ideal operating conditions. Let’s delve deeper into the key technologies driving this innovation:

Passive Cooling Methods

Passive cooling mechanisms leverage the principles of thermodynamics to dissipate heat from battery modules without the need for external energy input. These methods serve as reliable and cost-effective solutions for managing temperature fluctuations. Some common passive cooling techniques include:

- Heat Sinks: Heat sinks are passive heat exchangers that facilitate the transfer of heat away from the battery cells to the surrounding environment. These metallic or composite structures feature extended surfaces to increase heat dissipation efficiency.

- Phase Change Materials (PCMs): PCMs are substances capable of storing and releasing thermal energy during phase transitions, such as melting and solidification. When integrated into battery systems, PCMs absorb excess heat during charging or high-demand scenarios and release it later as temperatures decrease, effectively regulating the thermal profile.

- Cooling Fins: Cooling fins, also known as heat fins or radiator fins, enhance heat dissipation by increasing the surface area available for convective cooling. These fin-like structures are often attached to heat sinks or enclosures, facilitating efficient heat transfer to the surrounding air.

Active Cooling Systems

Active cooling solutions employ mechanical or refrigeration-based techniques to actively remove heat from battery modules, ensuring precise temperature control and optimal performance. These systems are particularly effective in high-demand or high-temperature environments. Key active cooling methods include:

- Air Cooling: Air cooling systems utilize fans or blowers to circulate ambient air around battery modules, promoting convective heat transfer and maintaining temperature within predefined limits. This cost-effective approach is widely used in various applications, ranging from consumer electronics to electric vehicles.

- Liquid Cooling: Liquid cooling systems employ coolant fluids, such as water or specialized refrigerants, to absorb and transport heat away from battery cells. This closed-loop system ensures efficient heat dissipation and temperature regulation, making it suitable for high-power or high-temperature applications where air cooling may be insufficient.

- Compression Refrigeration: Compression refrigeration systems, commonly known as refrigeration units, utilize compressors, condensers, and evaporators to actively remove heat from battery modules. These sophisticated systems offer precise temperature control and can maintain sub-ambient temperatures if required, making them ideal for demanding industrial or automotive applications.

Temperature Monitoring Sensors and Measurement Principles

Temperature monitoring forms the cornerstone of over temperature protection circuit, enabling early detection of thermal anomalies and timely intervention to prevent potential hazards. Various sensor technologies and measurement principles are employed to accurately monitor temperature parameters within battery systems:

- Thermocouples: Thermocouples consist of two dissimilar metal wires joined at one end. When subjected to temperature variations, they generate a voltage proportional to the temperature difference, allowing for precise temperature measurements over a wide range.

- Thermistors: Thermistors are temperature-sensitive resistors whose electrical resistance changes significantly with temperature variations. These semiconductor devices offer high sensitivity and accuracy, making them well-suited for temperature monitoring applications in battery systems.

- Infrared (IR) Sensors: IR sensors detect infrared radiation emitted by objects based on their temperature. These non-contact sensors provide fast and remote temperature measurements, allowing for real-time monitoring of battery modules without physical contact, ideal for applications where direct access may be limited or hazardous.

By harnessing the synergistic capabilities of passive cooling methods, active cooling systems, and advanced temperature monitoring technologies, stakeholders can effectively fortify battery systems against thermal challenges, ensuring safety, reliability, and longevity.

Benefits of Incorporating Overtemperature Protection

On top of safety, there are many benefits provided by dialing in thermal management and over temp protection including:

Improved Battery Lifespan: Keeping batteries operating at moderate steady-state temperatures maximizes cycle life over years of operation. This directly prevents age-related capacity degradation that occurs during exposure to temperature extremes.

Enhanced Performance: Peak electrical performance happens in battery cells around room temperature. Avoiding operation near upper limits prevents issues like reduced charging acceptance.

Investment Protection: Letting temperatures escalate without regulation leads to premature failure of cells and necessitates expensive replacement costs and project delays.

With lithium battery technologies costing anywhere from $100 to over $200 per usable kilowatt-hour, taking measures to extend operational lifespan through over temperature protection devices just makes sense.

Additional Key Factors for Thermal Management

While we have covered core overtemp concepts, a few final points worth mentioning around thermal design include:

- Chemistry-Specific Constraints: Cell limitations based on lithium-ion subtype, lead-acid construction, etc. alter thermal sensitivity.

- Electrical & Thermal Modeling: Advanced modeling using tools like COMSOL Multiphysics optimizes heat removal.

- Uniformity & Hot Spots: Careful thermal design avoids internal hot zones devoid of cooling.

- System Monitoring: Tracking cooling equipment functionality and health allows preventative maintenance.

There is incredible complexity around thermal energy dynamics in battery deployments. Working with experienced specialists like those at MOKOENERGY helps simplify selection of BMS protective measures and supplemental temperature moderation equipment.

Let MOKOENERGY Handle Your Battery Heating Headaches

In summary, unchecked overheating destroys batteries through accelerated performance degradation and risks dangerous thermal runoff. Yet purpose-built BMS solutions with properly matched cooling technologies prevent these pitfalls via automated control mechanisms.

MOKOENERGY offers cost-effective overtemp protection packages with remote monitoring and control to extend the service lifetime for your energy storage investment. Contact our professionals today to discuss your project requirements!