Lithium-ion batteries have become the dominant rechargeable battery technology used in consumer electronics like laptops and smartphones. It also has been used for energy storage in hybrid electric vehicle fields. As lithium-ion batteries discharge during use, it’s important for users to understand the battery SOE (state of energy) – or how much charge is remaining. Knowing the state of energy can help you better manage the runtime of your devices before the next recharge is needed.

In this blog, we will take a closer look at the factors that affect the state of energy measurements in lithium-ion batteries. We will also discuss techniques for accurately estimating the battery SOE, and Mokoenergy’s services for lithium-ion battery care to optimize the battery’s health and lifetime. Understanding the state of energy of your lithium-ion batteries can help you better manage your battery-powered devices.

What is the Battery SOE (State of Energy)?

The battery management system (BMS) is crucial for ensuring the safe, reliable, and efficient operation of lithium-ion batteries (LIBs). A key role of the BMS is to monitor the battery’s operation and report on its status. Additionally, the BMS provides accurate estimates of key LIB parameters, including state of charge (SOC), state of health (SOH), state of energy (SOE), and remaining useful life (RUL). Of these, battery SOE is a particularly important parameter tracked by the BMS.

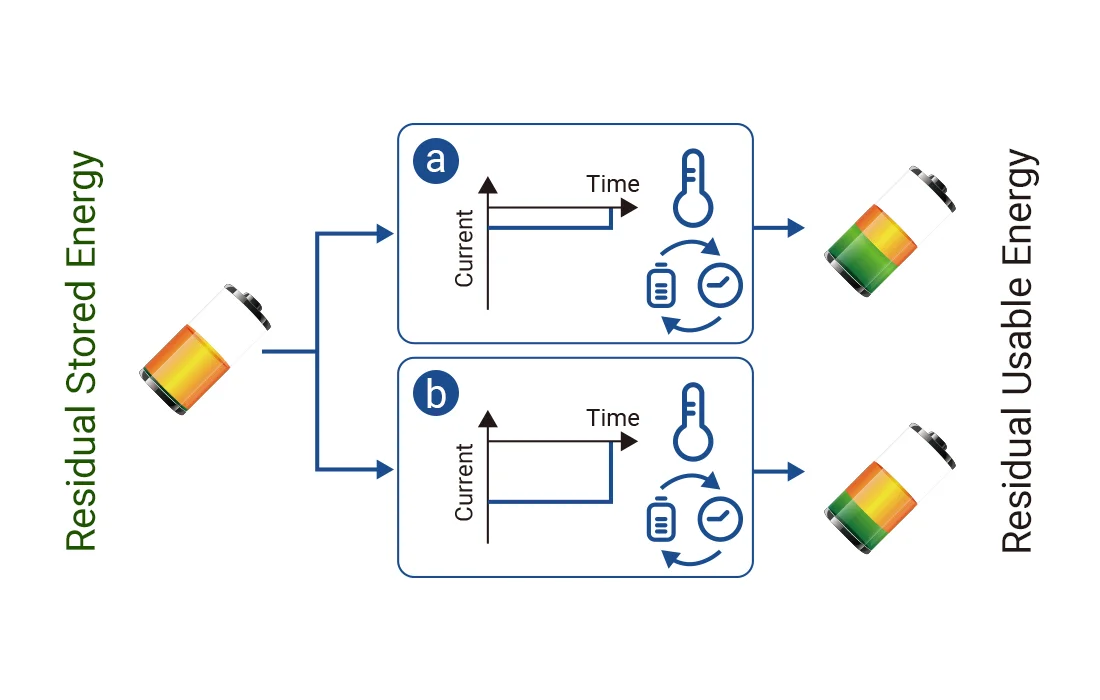

Battery SOE refers to the ratio between the battery’s remaining available energy and its maximum available energy. It is typically represented as a percentage between 100% (fully charged) and 0% (fully discharged). Tracking SOE allows the BMS to determine how much usable energy is left in the battery at any given time. This is one of the most critical pieces of information provided by the BMS, as it indicates the current energy level and remaining driving range for electric vehicle applications. Having insight into the state of energy allows users to predict how much longer a device can continue operating before the battery is depleted and needs to be recharged. An accurate battery SOE estimation is vital for proper LIB and BMS operation.

Battery SOE refers to the ratio between the battery’s remaining available energy and its maximum available energy. It is typically represented as a percentage between 100% (fully charged) and 0% (fully discharged). Tracking SOE allows the BMS to determine how much usable energy is left in the battery at any given time. This is one of the most critical pieces of information provided by the BMS, as it indicates the current energy level and remaining driving range for electric vehicle applications. Having insight into the state of energy allows users to predict how much longer a device can continue operating before the battery is depleted and needs to be recharged. An accurate battery SOE estimation is vital for proper LIB and BMS operation.

Factors that Affect Battery SOE Readings

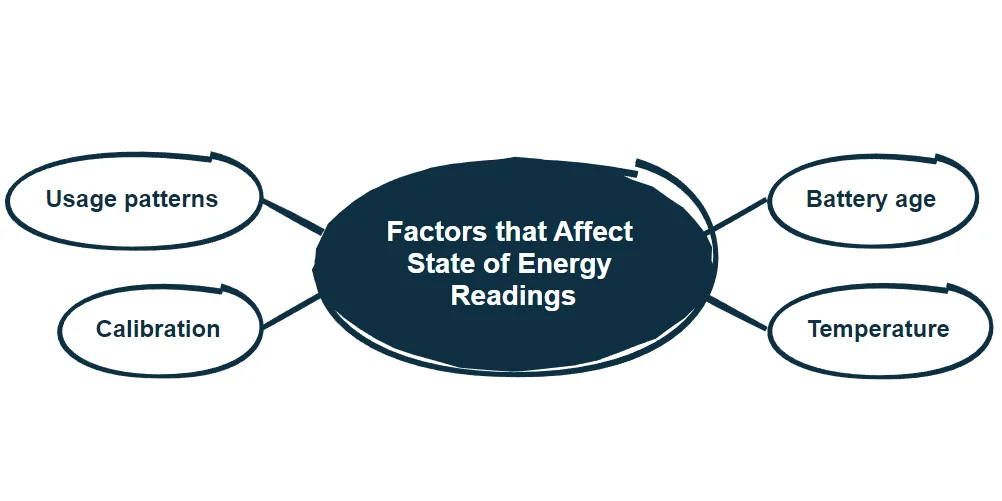

Factors that affect the battery State of Energy readings can be attributed to a multifaceted interplay of four crucial elements, each exerting its influence on the accuracy and reliability of energy measurements. These factors include:

Battery Age

The age of the battery has a great effect in determining the state of energy readings. Over time, batteries undergo chemical changes and degradation, affecting their overall capacity and performance. As batteries age, their ability to hold and deliver a consistent level of energy diminishes, directly impacting the precision of energy measurements. Monitoring and understanding the battery SOE is essential to ensure that energy readings remain dependable over extended periods.

Temperature

Temperature fluctuations can significantly impact the state of energy readings. Extreme temperatures negatively impact battery life. High heat hastens battery degradation and shortens overall lifespan, while cold temporarily lowers capacity. Accounting for temperature variations is crucial for accurate energy measurements, necessitating the implementation of temperature compensation mechanisms in energy monitoring systems.

Usage Patterns

The manner in which energy-consuming devices are utilized, commonly referred to as usage patterns, directly affects energy readings. Fluctuations in energy demand and usage intensity can lead to dynamic changes in voltage and current levels, impacting the accuracy of measurements. Understanding and analyzing usage patterns, such as peak demand periods or cyclic variations, are essential for calibrating energy monitoring systems to account for these variations and provide precise energy readings under diverse operational scenarios.

Calibration

Calibration is a critical factor that ensures the accuracy and reliability of energy readings. Regular calibration of energy monitoring instruments against known standards helps to correct any deviations or inaccuracies that may arise over time. The precision of measurement instruments can drift due to environmental conditions, component aging, or other factors. Thus, periodic calibration is necessary to maintain the integrity of energy readings and uphold the trustworthiness of the data generated by energy monitoring systems.

Battery SOE Estimation

There are various methods for estimating battery State of Energy (SOE), including the direct calculation method, power integration method, OCV method, model-based filtering algorithm, machine learning method, and joint estimation method.

Direct Calculation Method:

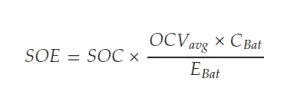

- Utilizes a constant average voltage to calculate SOE from current SOC, total battery energy, capacity, and average voltage (Equation 1).

(Equation 1) - Simple and practical but prone to large errors due to voltage approximation, impacting accuracy if SOC has errors.

Power Integration Method:

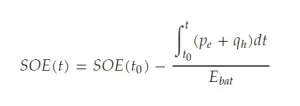

- Similar to AH for SOC estimation (Equation 2)

(Equation 2) - Simple, doesn’t require SOC estimation but accumulates errors due to sensor inaccuracies.

OCV Method:

- Utilizes correlation between OCV and battery SOE.

- Limited by the time needed for stable OCV, making it challenging in dynamic working environments.

Model-Based Filtering Method:

- Employs power integration for SOE estimation, corrected by filtering algorithms like KF, PF, and H-infinity.

- Using high-accuracy estimation minimizes cumulative SOE errors, but relies heavily on an accurate battery model.

Machine Learning Method:

- A recent trend involves using machine learning to estimate SOE.

- Approaches include using current and temperature as inputs for neural networks or predicting future voltage with Monte Carlo sampling. Accuracy depends on training data quality.

Joint Estimation Method:

- First estimates battery SOC, then derives SOE through the SOC-SOE relationship.

- Joint state-of-energy estimation methods offer improved accuracy over single estimation techniques but depend on identifying clear correlations between SOE and other battery states.

Possible Effects of Low State of Energy

- Reduced Capacity: Low energy levels indicate that the battery has less charge stored. This leads to a reduction in the overall capacity of the battery, meaning it can provide power for a shorter duration.

- Voltage Sag: As the battery depletes, its voltage decreases. This can result in voltage sag, where the output voltage temporarily drops during high-demand situations. Voltage sag can affect the performance of electronic devices relying on a stable power supply.

- Decreased Performance: Devices powered by a low-energy lithium-ion battery may experience reduced performance. For example, smartphones may have slower processing speeds, and laptops may have shorter runtimes.

- Risk of Deep Discharge: Allowing a lithium-ion battery to reach an extremely low state of charge may lead to deep discharge. Deep discharging can harm the battery’s overall health and reduce its lifespan.

- Cycling Issues: Lithium-ion batteries have a limited number of charge-discharge cycles. Allowing the battery to consistently reach low energy levels can contribute to faster degradation and reduce the overall number of cycles the battery can undergo.

- Increased Self-Discharge: Batteries with low energy levels tend to have a higher self-discharge rate. This means that they lose their charge more quickly when not in use, leading to a shorter shelf life.

- Voltage Cutoff and Protection: Many lithium-ion batteries include built-in protection circuits that prevent over-discharge. When the battery reaches a critically low level, it may trigger a voltage cutoff to protect the battery from damage. This can result in the device powering off abruptly.

- Safety Concerns: Operating a lithium-ion battery at very low energy levels can pose safety risks. It may lead to issues such as over-discharge-induced thermal runaway.

How Will MOKOENERGY Play Its Role in Battery Health Protection

MOKOEnergy plays a pivotal role in safeguarding battery health through our advanced battery management systems (BMS) which are renowned for their efficacy and reliability. With a global presence and partnerships in countries like the United States and Australia, MOKOEnergy ensures that its BMS adheres to international standards such as IEC 61508, providing clients with products that meet regulatory requirements.

The emphasis on battery state of energy (SOE) monitoring is a cornerstone of MOKOEnergy’s approach to Lithium Battery Protection. By incorporating cutting-edge technology, MOKOEnergy’s BMS monitors and manages the battery SOE, optimizing performance and extending the lifespan of lithium batteries. This capability is particularly crucial in diverse applications, ranging from energy storage systems to electric vehicles, industrial sectors, and portable devices. MOKOEnergy’s commitment to battery health protection is underscored by our comprehensive suite of solutions. Choose us as your trusted partner in ensuring the safety and longevity of battery systems worldwide.