- What is BMS for new energy lithium battery?

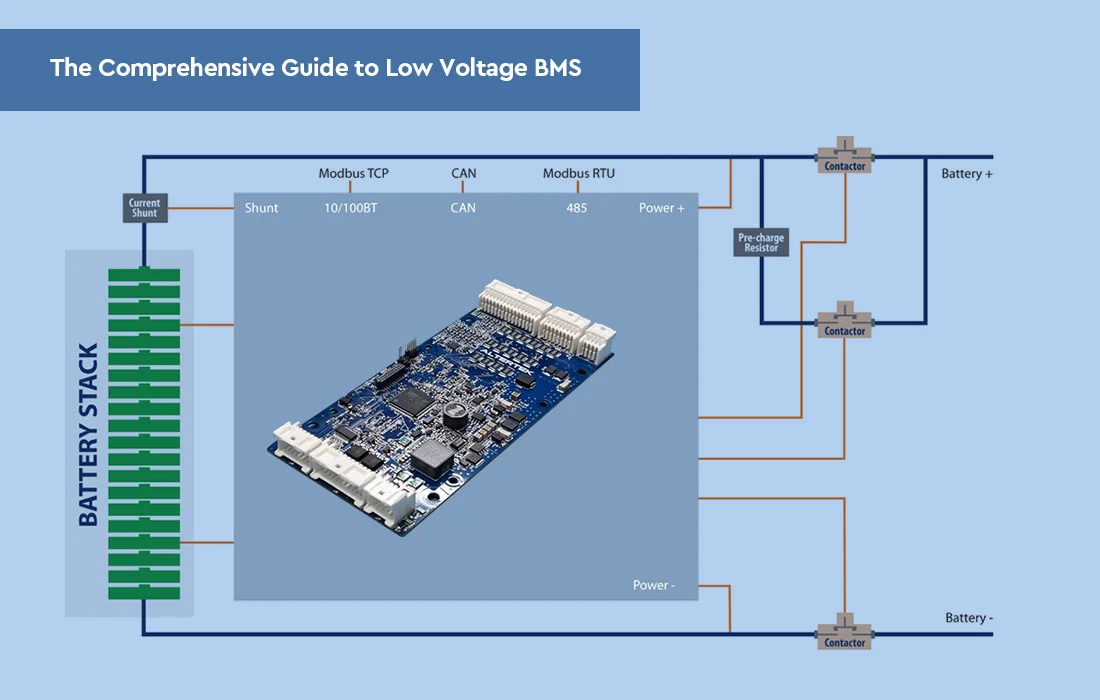

A BMS functions as the intermediary between the battery and the user, with its primary focus on secondary batteries. Its purpose is to enhance battery utilization, often referred to as the “brain” of power battery systems. Essentially, it serves as the cognitive center of lithium batteries, receiving and transmitting data from and to batteries and external sources through various ports. Once this information undergoes thorough analysis and processing, the BMS issues instructions to execute tasks. Given its critical significance in the realm of new energy vehicles, the BMS industry has consistently drawn the interest of numerous lithium battery manufacturers. - Why do we need BMS for new energy lithium batteries?

Lithium-ion batteries find extensive application in remote monitoring devices that require prolonged standby periods due to their elevated operational voltage, compact dimensions, lightweight nature, impressive energy density, absence of memory effects, non-polluting characteristics, minimal self-discharge, and extended cycling durability. Nevertheless, lithium batteries also exhibit certain inherent drawbacks, which can be categorized into the following two aspects.

(1) Safety

Lithium-ion batteries have inadequate safety features, leading to issues such as explosions. Specifically, lithium-ion batteries that use lithium cobaltate as the cathode material cannot handle high-current discharges and exhibit subpar safety measures. Furthermore, nearly all lithium-ion batteries experience some level of damage when overcharged or over-discharged.

Lithium-ion batteries are highly temperature-sensitive as well. Excessively high temperatures can lead to electrolyte decomposition, ignition, or even explosion, while excessively low temperatures can result in a notable decline in lithium-ion battery performance, impacting the proper functioning of devices.

Because of the constraints imposed by the lithium battery manufacturing process, variations occur in the internal resistance and capacity of individual batteries. When several lithium batteries are connected in series, these differences in charge and discharge rates among the batteries lead to suboptimal utilization of their overall capacity. To address this issue, a dedicated protection system is employed during the practical use of lithium batteries to oversee the battery’s health, effectively managing their utilization in real-world applications.

(2) Maintainability

In cold temperatures, it becomes challenging to accurately anticipate capacity deterioration and power performance, thereby reducing the equipment’s maintainability. Instruments that are on-line for a long period of time have to be replaced periodically, and remote monitoring equipment works at decentralized locations and the distance between each location is long, so the workload of replacing batteries is high and costly.

To minimize maintenance efforts and costs, it is essential for a lithium battery management system to incorporate a precise power status estimation feature. This feature ensures an accurate assessment of the power status of lithium batteries, enabling more focused and efficient battery replacement procedures. Additionally, the lithium battery management system should operate with low power consumption to decrease maintenance frequency and extend the battery lifespan. Consequently, the thoughtful design of a lithium battery management system holds significant importance for the prolonged, uninterrupted power supply of remote monitoring instruments.

MORE: Will the new energy storage BMS be more complex than the vehicle battery BMS?