The world is witnessing a significant shift towards sustainable energy solutions, and battery technology plays a pivotal role in this transition. Battery Management Systems (BMS) have become vital components, ensuring the efficient and safe operation of rechargeable batteries. At the core of these systems, BMS chips, also known as battery management chipsets, bring intelligence and sophistication to battery management. These chips play a crucial role in monitoring, safeguarding, and optimizing battery performance, rendering them indispensable across diverse industries. In this article, we will delve deeper into the significance of BMS chips, explore advancements in their technology, and provide a comprehensive analysis of key BMS chip manufacturers in the market.

What are BMS Chips?

Battery management system chips are sophisticated integrated circuits designed specifically to manage battery packs. They act as the brain behind BMS systems, enabling crucial functions such as voltage and current monitoring, temperature sensing, cell balancing, charge and discharge control, and fault protection. The primary objective of BMS chips is to maximize battery life, enhance safety, and improve overall battery performance.

How Does the battery management chip Work?

BMS chips function by continuously monitoring individual cells or modules within a battery pack. They gather crucial data on parameters such as voltage, current, and temperature to assess the battery’s health and performance. Based on this data, the battery management system chip can make real-time decisions, such as balancing cell voltages to prevent overcharging or discharging, adjusting charging rates for optimum efficiency, and implementing safety protocols in case of anomalies.

4 Types of BMS Chipsets and their main manufacturers

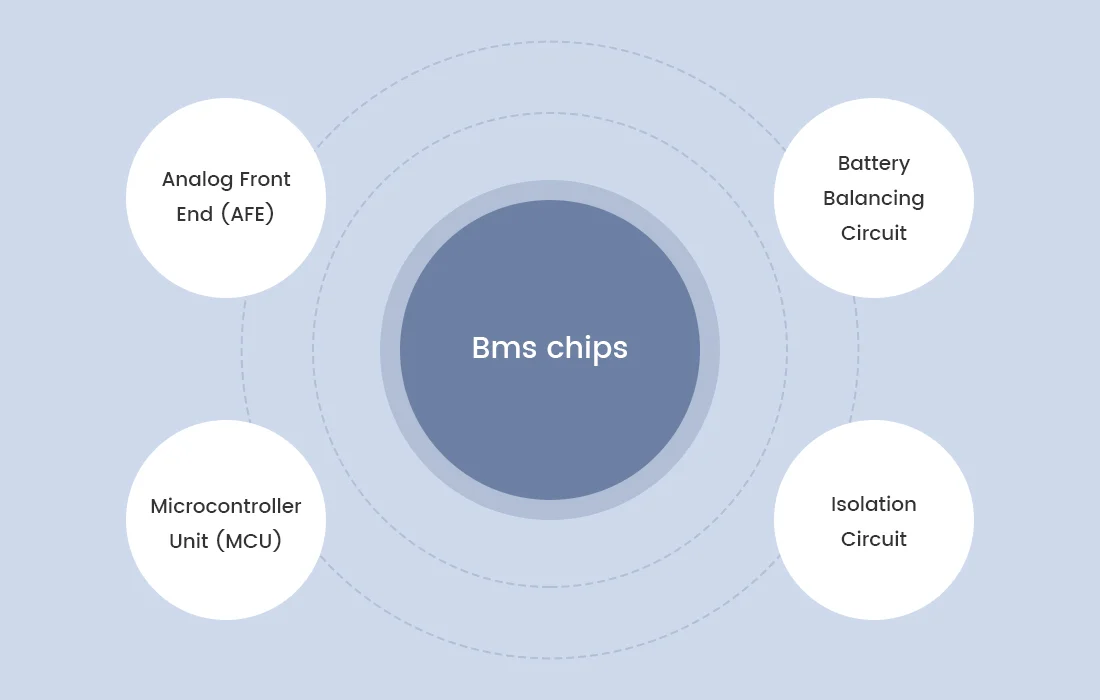

battery management chips come in various types, catering to different battery pack configurations and chemistries. They may range from simple single-cell protection chips to complex multi-cell management chips. Some of the key components commonly found in BMS chips include:

Analog Front End (AFE) Module: The AFE module is responsible for battery information acquisition and status monitoring. It comprises sensor interfaces, analog signal conditioning circuitry (including impedance transformation, programmable gain amplification, filtering, and polarity conversion), analog switches, sample-and-hold circuitry, ADCs (Analog-to-Digital Converters), data buffers, and control logic. In some cases, the AFE module may also integrate MCU (Microcontroller Unit), DAC (Digital-to-Analog Converter), and various driver circuits. The main manufacturer of AFE is ADI, which has collaborated with automotive companies like General Motors to develop wireless BMS systems and platforms that enable real-time data monitoring and analysis.

Battery Balancing Circuit: To ensure optimal battery pack performance and longevity, BMS chips employ battery balancing circuits. These circuits equalize the charge across individual cells, preventing overcharging of some cells and over-discharging of others. By maintaining balanced cell voltages, BMS chips enhance the overall efficiency and health of the battery pack.

Microcontroller Unit (MCU): The MCU serves as the central processing unit of the battery management chips. It handles control and computation tasks, managing functions such as relay control, state-of-charge estimation, balancing control, and data collection for voltage, current, and temperature readings. The MCU Suppliers mainly include Texas Instruments (TI), STMicroelectronics (ST), NXP, Semiconductors, Infineon Technologies, and Renesas Electronics.

Isolation Circuit: Isolation circuits are crucial for high-voltage and low-voltage modules to achieve electrical isolation. They ensure safe and reliable communication between different parts of the BMS while mitigating potential risks of electrical faults. The main Digital Isolation Suppliers are Analog Devices Inc. (ADI), Texas Instruments (TI), and Silicon Labs.

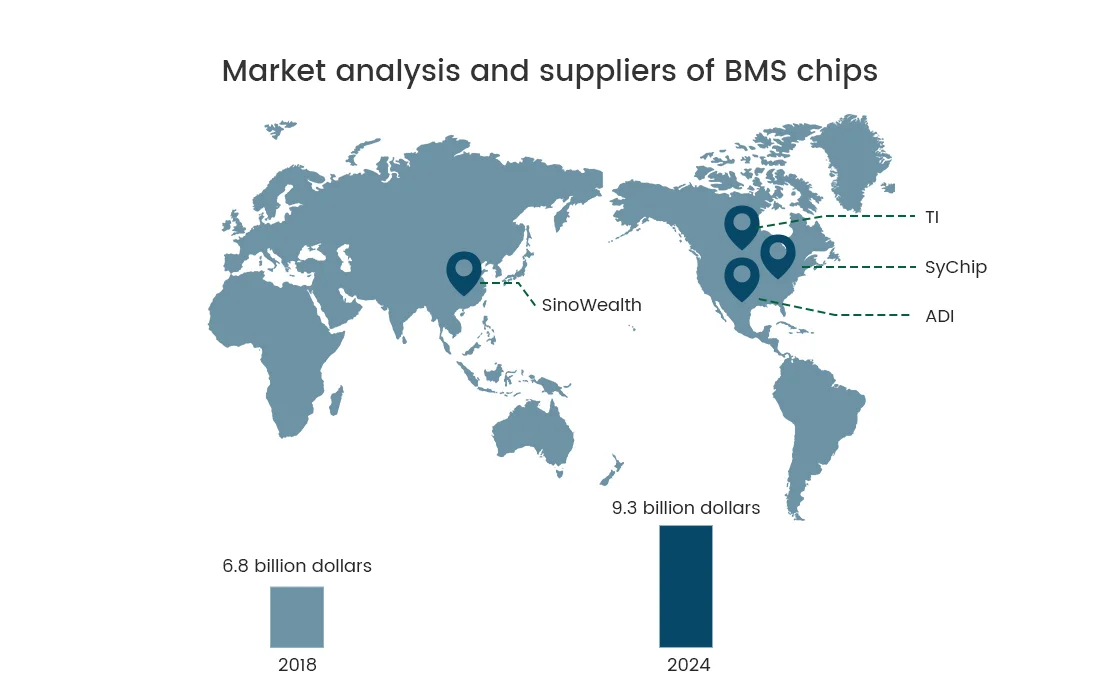

Compare 4 main BMS Chip Manufacturers: TI vs ADI vs SyChip vs SinoWealth

The BMS chip market is dominated by several leading manufacturers, each providing distinctive features and capabilities. Below, we compare some key BMS chip suppliers and their contributions to the industry:

Texas Instruments (TI): TI is a global leader in the BMS chip market, known for its wide range of products and dominance in vehicle-mounted and industrial applications. With a market share of approximately 31% in 2020, TI offers over 500 BMS battery management chip models. Recent advancements in TI’s products include improved accuracy and low power consumption, making them highly competitive in the industry.

Analog Devices Inc. (ADI): Following closely behind TI, ADI holds a 17% market share in the battery management system chip market. ADI gained prominence through the acquisition of Maxim, bolstering its position in the automotive and data center sectors. Their recent product launches include innovative BMS charging management and monitoring solutions for various automotive specifications, addressing the increasing demand for electric vehicles and industrial applications.

SyChip: SyChip is a notable player focusing on lithium battery protection chips. Their specialization in single-wafer technology has resulted in cost-effective and highly integrated battery protection chips. SyChip’s products stand out with low static and shutdown power consumption, making them ideal for applications where energy efficiency is crucial.

SinoWealth: As a Chinese BMS chip company, SinoWealth has seen significant growth in recent years. Their products mainly cater to consumer electronics such as smartphones and electric bicycles. Notably, SinoWealth’s advancements in high serial number battery sampling have allowed simultaneous sampling of 5 to 16 battery strings, expanding their application to automotive-grade use.

| Manufacturer | Key Features | Market Focus |

| Texas Instruments (TI) | Deepened vehicle-mounted BMS layout, improved accuracy, and low power consumption | Automotive and Industrial Applications |

| Analog Devices Inc. (ADI) | Innovative BMS charging management and monitoring for various automotive specifications | Automotive and Industrial Applications |

| SyChip | Utilizes single-wafer technology, low static and shutdown power consumption | Various applications, specializing in lithium battery protection |

| SinoWealth | High serial number battery sampling, application in consumer electronics | Electric bicycles, smartphones, and expanding to automotive-grade applications |

Market Analysis of BMS Chips

Global battery management chip market

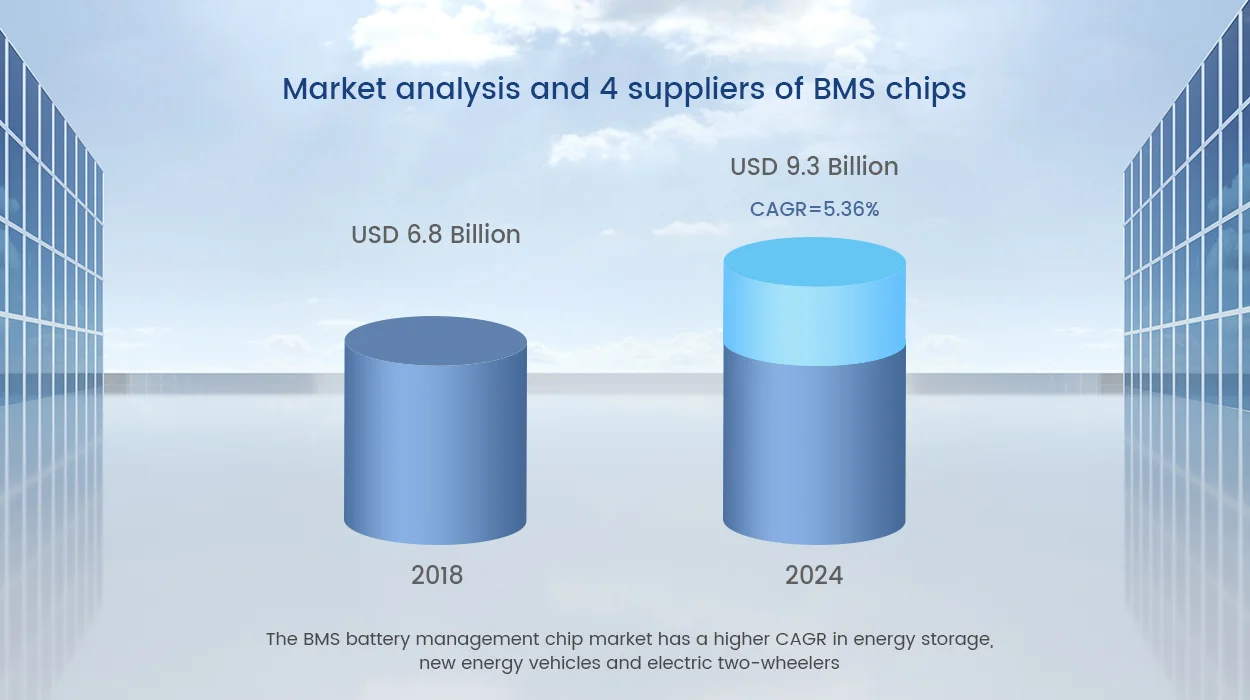

The global battery management chip market has experienced substantial growth in recent years, driven by increasing demand in energy storage, electric vehicles, and other related fields. Based on the data from Mordor Intelligence, the BMS battery management chip market was valued at US$6.8 billion in 2018 and is expected to reach US$9.3 billion by 2024, exhibiting a compound annual growth rate of 5.36%. Notably, the compound annual growth rates in energy storage, new energy vehicles, and electric two-wheelers segments are even higher, indicating the rapid expansion of these industries.

Chinese BMS chip market

In addition to the global market trends for BMS chips, it is essential to consider the significant developments in the Chinese BMS chip market. China, being a major player in the electric vehicle and renewable energy industries, plays a crucial role in driving the demand for battery management chips.

With the rapid expansion of the electric vehicle market and the government’s initiatives to promote sustainable energy solutions, the demand for BMS chips in China has soared. Chinese BMS chip manufacturers, such as SinoWealth, have been quick to capitalize on this trend by offering advanced and cost-effective solutions tailored to the Chinese market’s needs.

Moreover, China’s prowess in battery manufacturing and energy storage projects has also contributed to the surge in battery management system chip demand. As the nation continues to invest in clean energy projects and electric mobility, the need for sophisticated BMS chipsets will only grow.

Additionally, China has witnessed a rising number of BMS chip IC startups and small-scale BMS chip vendors, adding further competitiveness to the market. These players often focus on niche applications and customization to cater to specific industry demands.

What industries need BMS Chip Technology?

In recent years, BMS chip technology has witnessed significant advancements, leading to higher integration, increased accuracy, and reduced power consumption. These developments have had a profound impact on various industries:

Electric Vehicles: The automotive industry has witnessed a remarkable transition towards electric mobility, and BMS chip solutions play a crucial role in the efficiency and longevity of electric vehicle batteries. With advanced BMS chips, battery packs can be effectively monitored and controlled, optimizing charging and discharging cycles. As a result, electric vehicles can achieve longer ranges, improved reliability, and enhanced safety, accelerating the transition to a cleaner transportation future.

Consumer Electronics: BMS chips have revolutionized the battery management of consumer electronics, such as smartphones, tablets, and wearable devices. By ensuring accurate monitoring and optimal charging, these chips extend battery life and enhance user experience, reducing the need for frequent recharging.

Renewable Energy Systems: Renewable Energy Systems benefit from the integration of advanced BMS chips in energy storage, leading to significant improvements in efficiency and stability. By effectively managing energy storage, BMS chips enhance the ability to store excess energy and release it as needed, thereby promoting a more sustainable and reliable energy grid.

BMS Chips vs. BMS IC

While BMS chips refer to the individual integrated circuits responsible for managing batteries, BMS IC (Integrated Circuit) is a broader term encompassing the entire BMS system. A Battery Management IC may include multiple BMS chips and additional components, such as sensors, communication interfaces, and safety mechanisms. It serves as a comprehensive solution for battery management, enabling seamless communication between the BMS and the battery pack.

Customization and Flexibility with Mokoenergy’s BMS Chips

In the rapidly evolving battery landscape, the importance of customizable BMS chips cannot be overstated. Different battery chemistries and configurations demand tailored BMS solutions to maximize safety and performance. MOKOEnergy, a leading provider of battery management technologies, stands out with its commitment to flexibility and customization. Their BMS chips cater to specific customer needs across various applications, ensuring efficient battery management and supporting the development of innovative energy solutions.

Conclusion

The significance of BMS chips in the journey toward a sustainable future cannot be overemphasized. These powerful components are vital for optimizing battery performance, ensuring safety, and extending the lifespan of energy storage systems, electric vehicles, and consumer electronics. With continuous advancements in BMS chip technology, industries can benefit from higher efficiency, increased accuracy, and reduced power consumption, paving the way for a cleaner and more energy-efficient world. As the global demand for energy storage and electric mobility continues to rise, the importance of cutting-edge BMS chips will only grow, enabling a more sustainable and greener tomorrow. To explore the innovative BMS chip solutions offered by MOKOEnergy, we invite readers to learn more about their state-of-the-art battery management technologies and commitment to a sustainable future, contact us now.